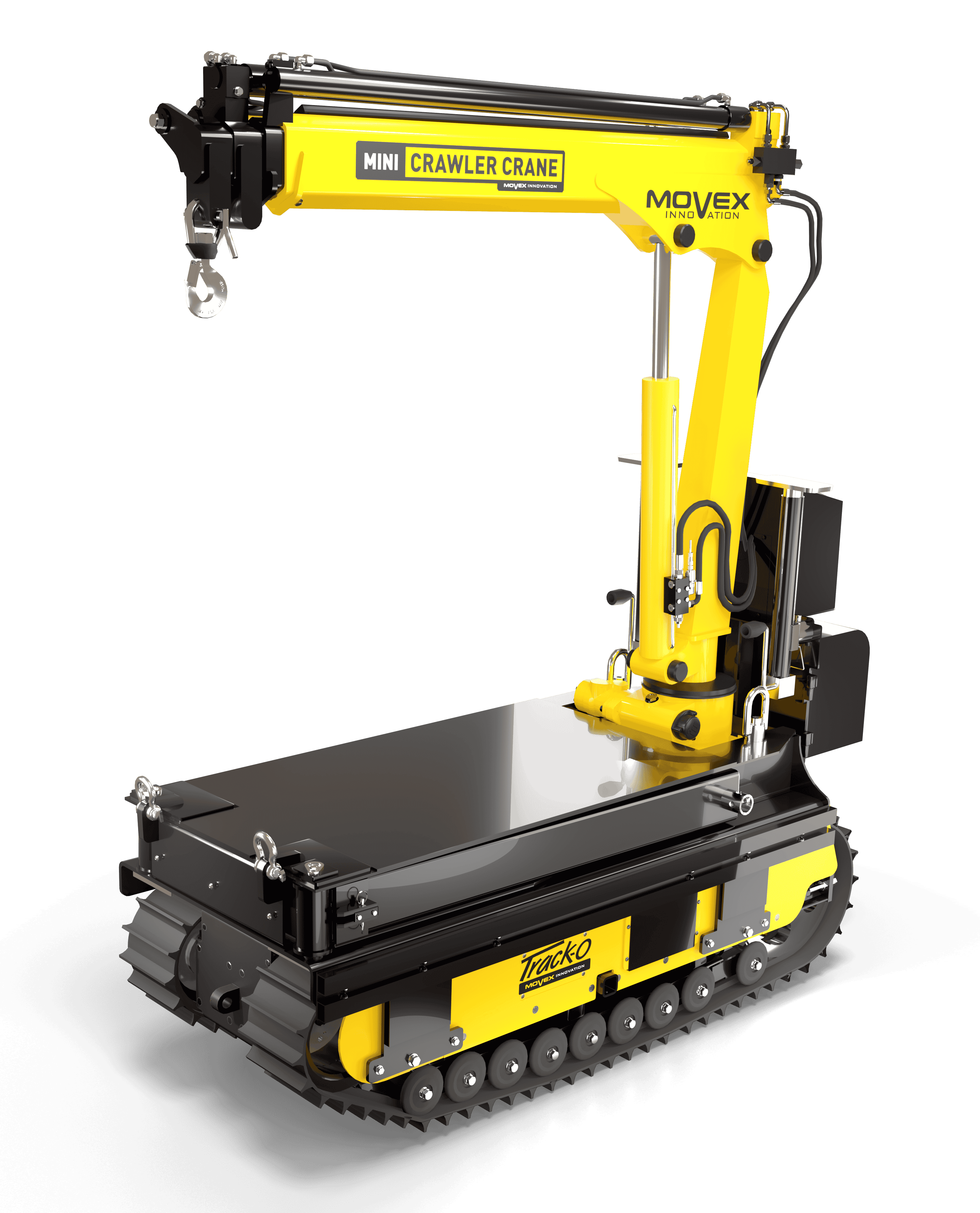

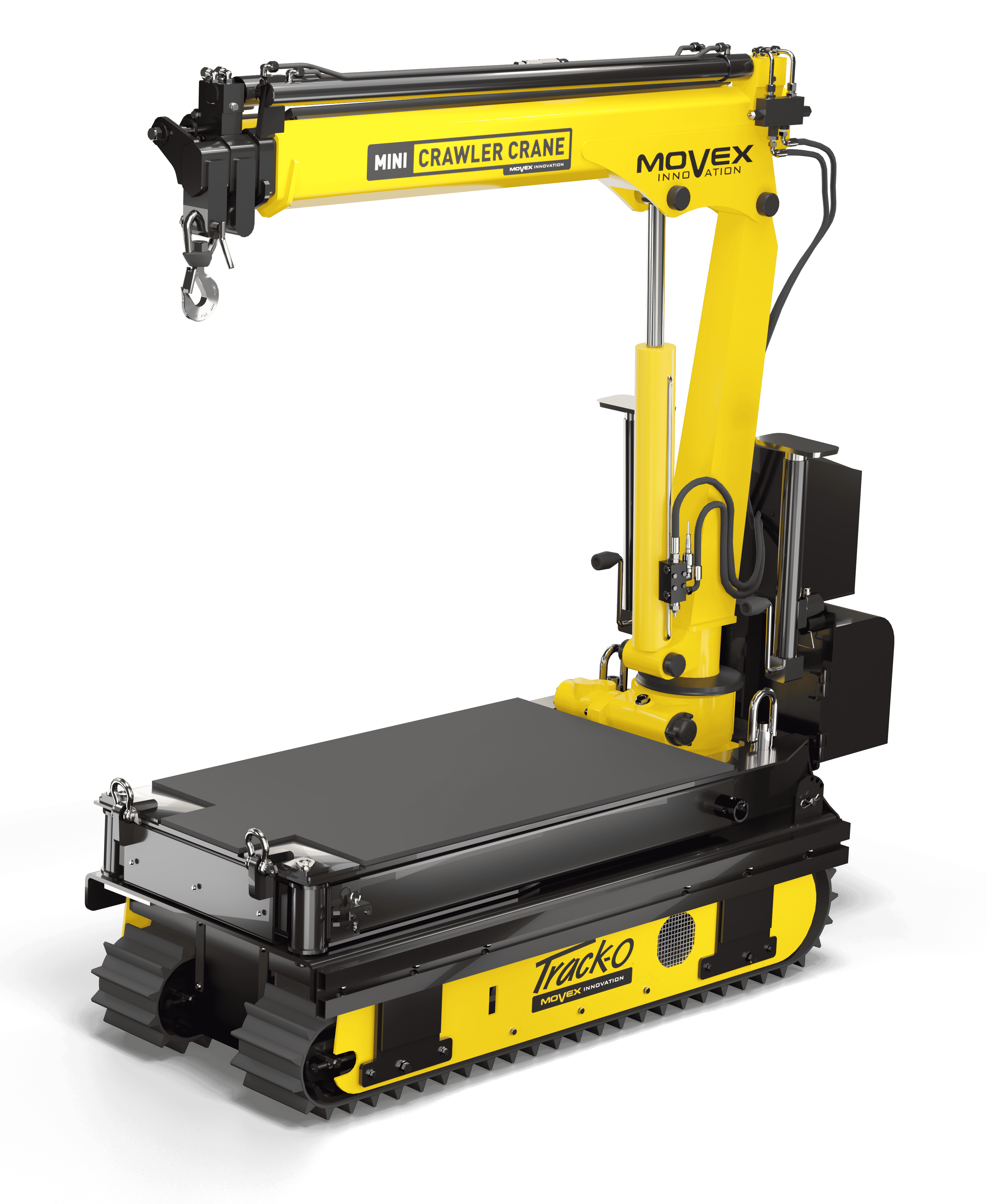

Heavy-duty material-handling equipment

for

aluminum smelters

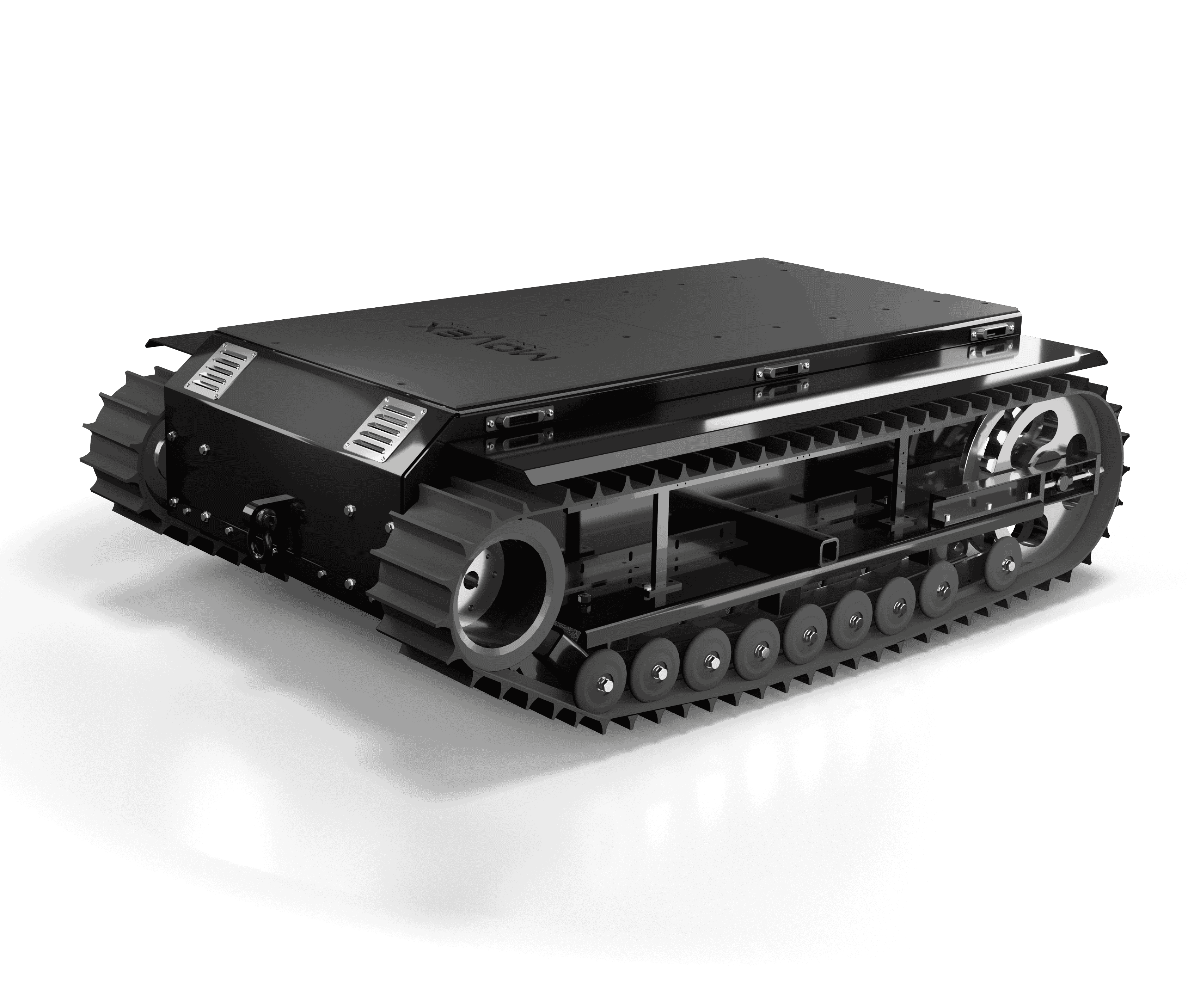

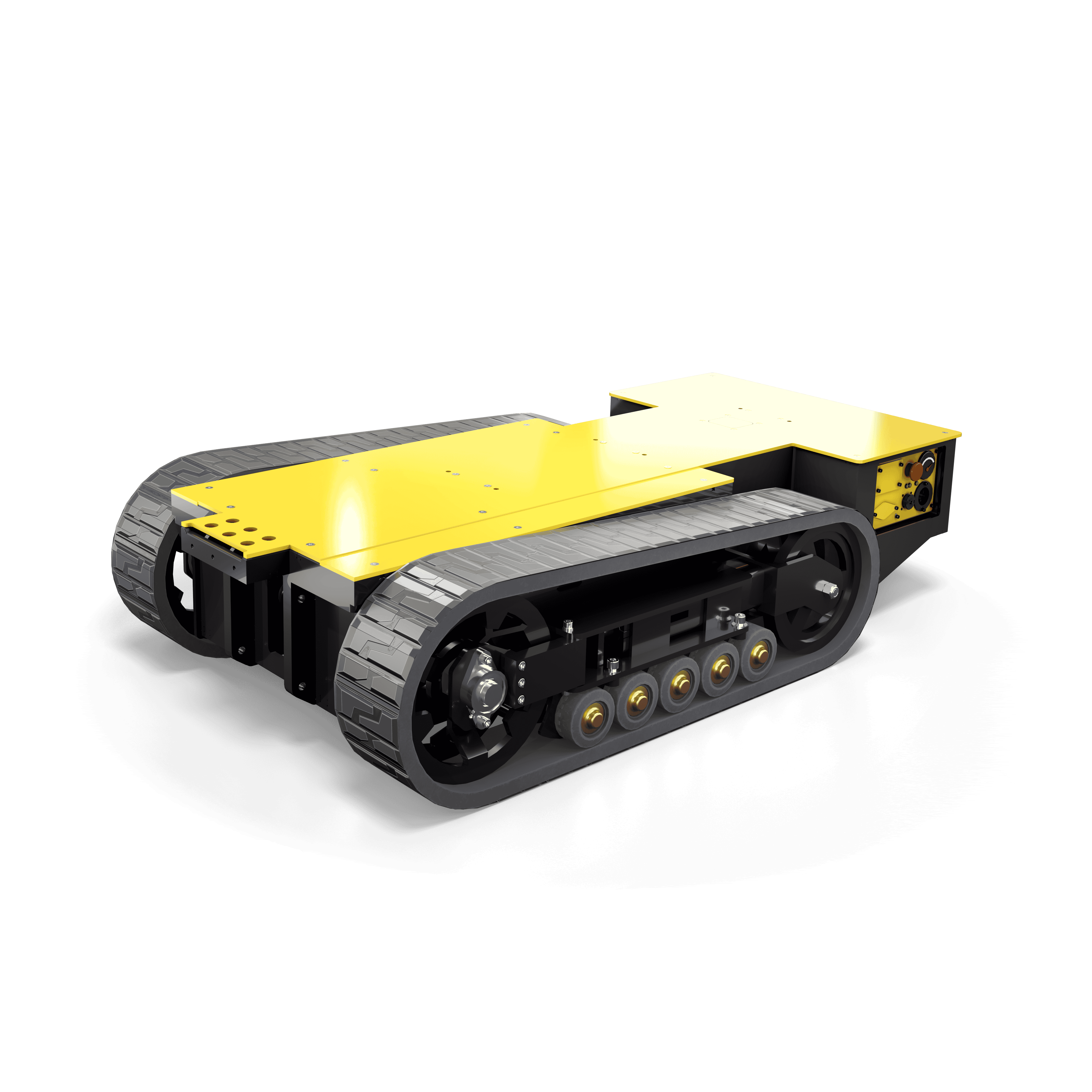

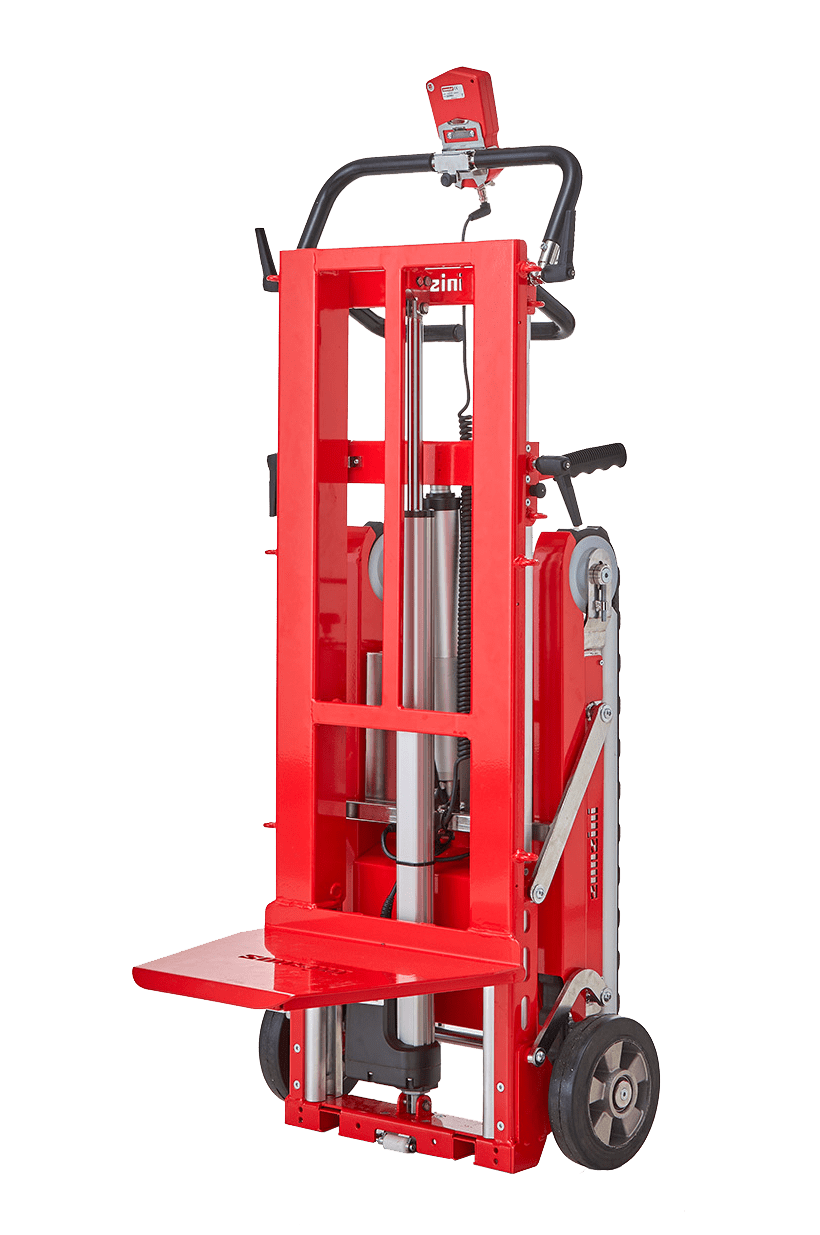

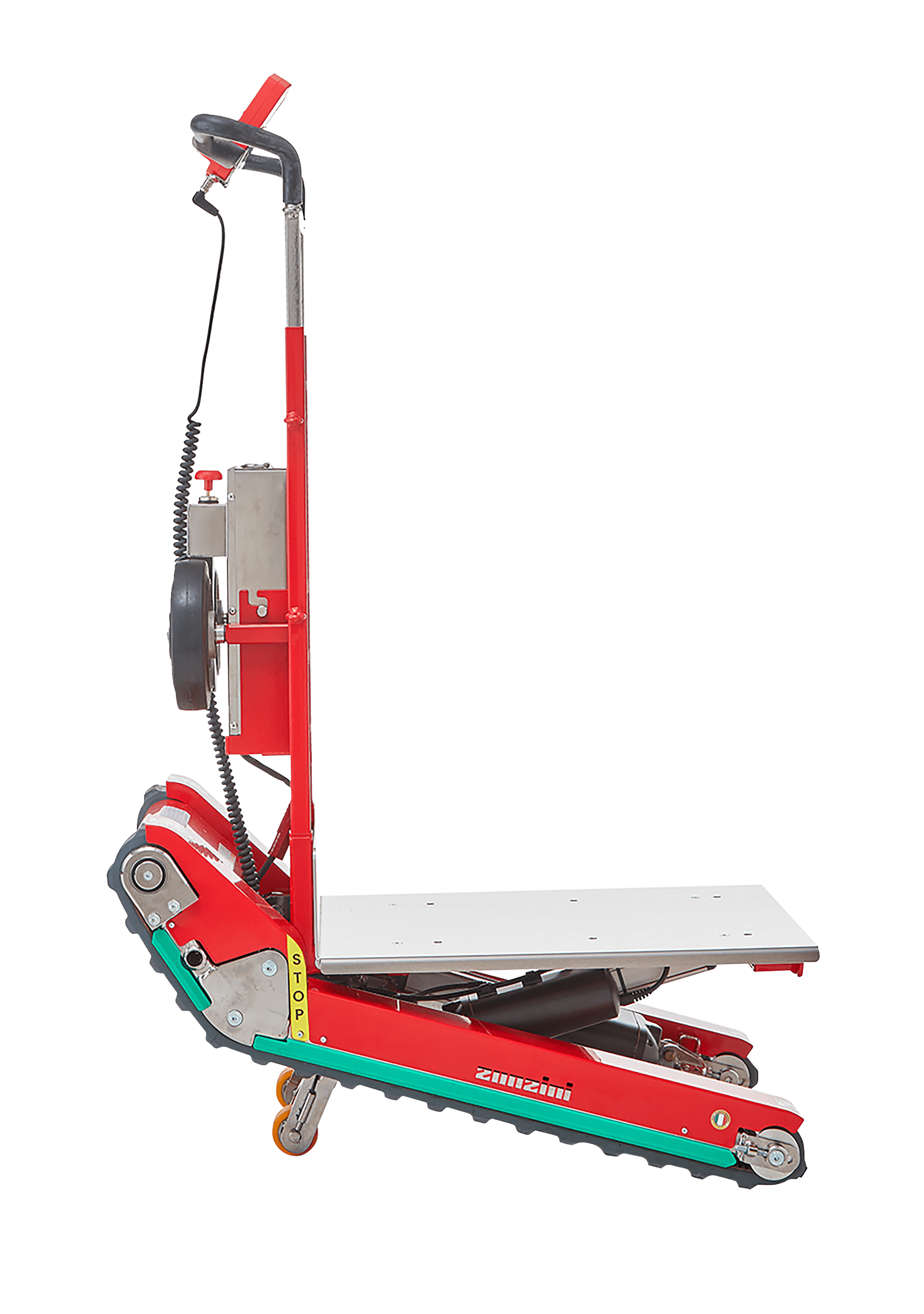

In the demanding environments of aluminum smelters, cleaning beneath a potline poses significant risks to worker safety. The confines of the operation demand compact material-handling equipment for aluminum smelters, and not just any equipment will do; it must be robust against magnetic fields.

Work crews are also constantly required to increase productivity and mitigate high operating costs. Movex Innovation’s heavy-duty equipment is tailored to the unique needs of aluminum smelters. Find out how we stand out.

What if we could help streamline your operations and boost your team’s productivity?

Designed for your aluminum smelter material-handling challenges

Why choose Movex Innovation?

- Robust and reliable equipment

- Ultra-compact design for restricted and narrow spaces

- Low vehicle height

- Resistant to magnetic fields

- Impressive bucket capacity and operation speed

- Reduced required labor & labor costs

- Decreased worker effort & risk of accidents

- Improved worker productivity

- Zero emissions

Trusted by the biggest names around the world

Need more information on our ultra-compact remote-controlled equipment?