How can construction material handling machines solve your manpower shortage?

Written by leonard | February 7th 2024

The construction industry is facing a big problem: not enough workers. This shortage is hitting businesses hard.

For example, according to an early 2023 report by the Associated Builders and Contractors (ABC), a US-based national construction trade association, estimates the shortage of construction workers at 546,000 in 2023. That number represents half a million workers over and above the normal pace of hiring to meet demand.

The situation is similar in Canada. In a recent interview with Global News, CIBC’s Deputy Chief Economist, Benjamin Tal, indicated that the job vacancy rate in the construction sector is at a record high, with around 80,000 unfulfilled positions. And the looming wave of retirements slated to start in the next few years (as the current construction work median age is 52) will only exacerbate the situation.

Construction work keeps economies growing, but without enough skilled workers, projects are getting delayed, costs are going up, and the workers who are still on the job are under a lot of pressure. This isn’t just a problem for construction sites; it affects the whole economy.

So, what are the solutions?

Industry experts agree that in order to mitigate the damaging effects of a never-ending labour shortage, construction companies must turn to new strategies to address the evolving work dynamic in their industries. As David DeSilva, Head of Construction at The Hartford, said in October 2023:

“Construction has been a late adopter of technology. This creates a new opportunity for leaders in the industry to find ways to include technology in their daily practice. As we’ve seen, the shortage of labour has created higher levels of workmanship issues due to a lack of capacity. This is the perfect opportunity to implement effective technology to better protect job sites.”

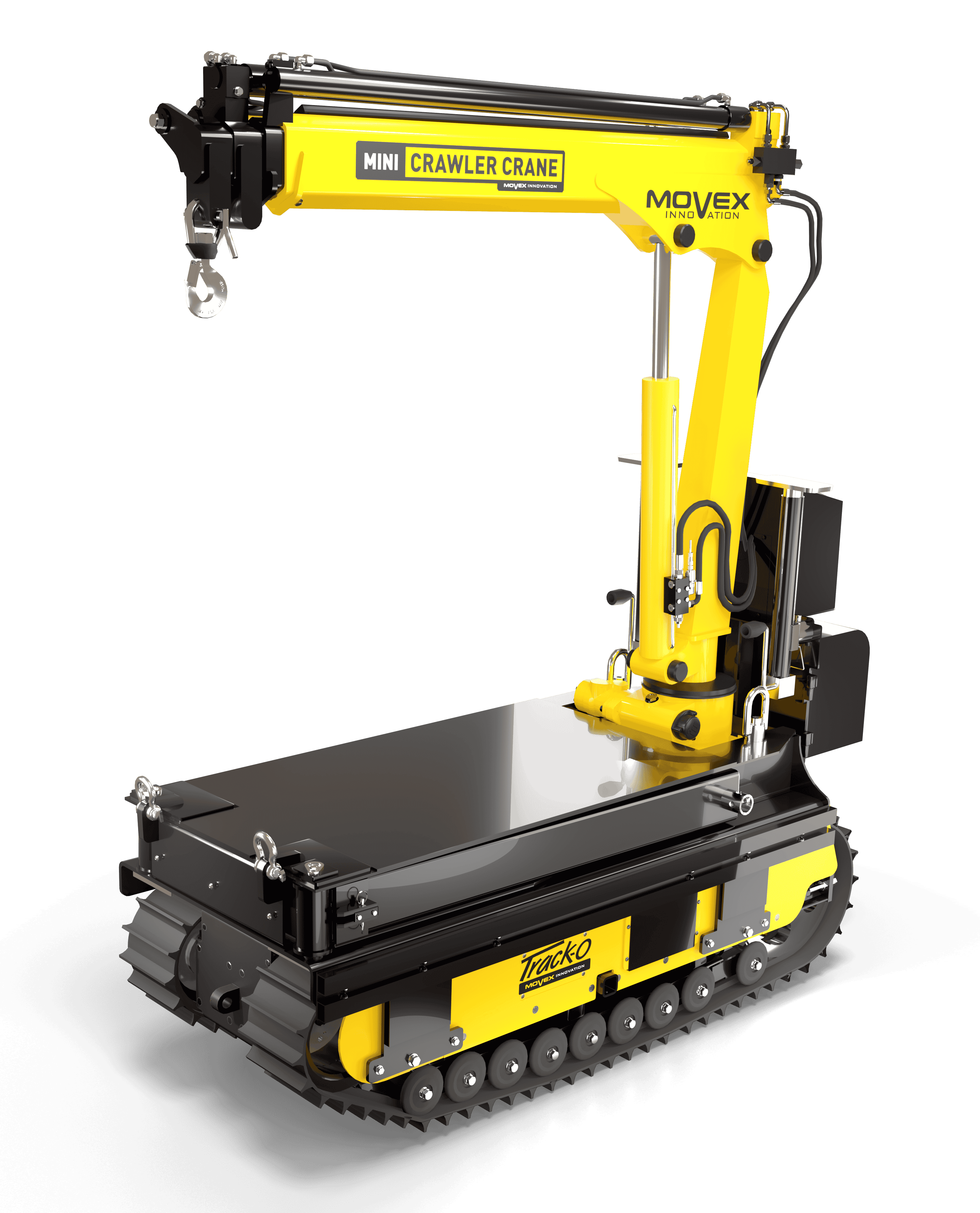

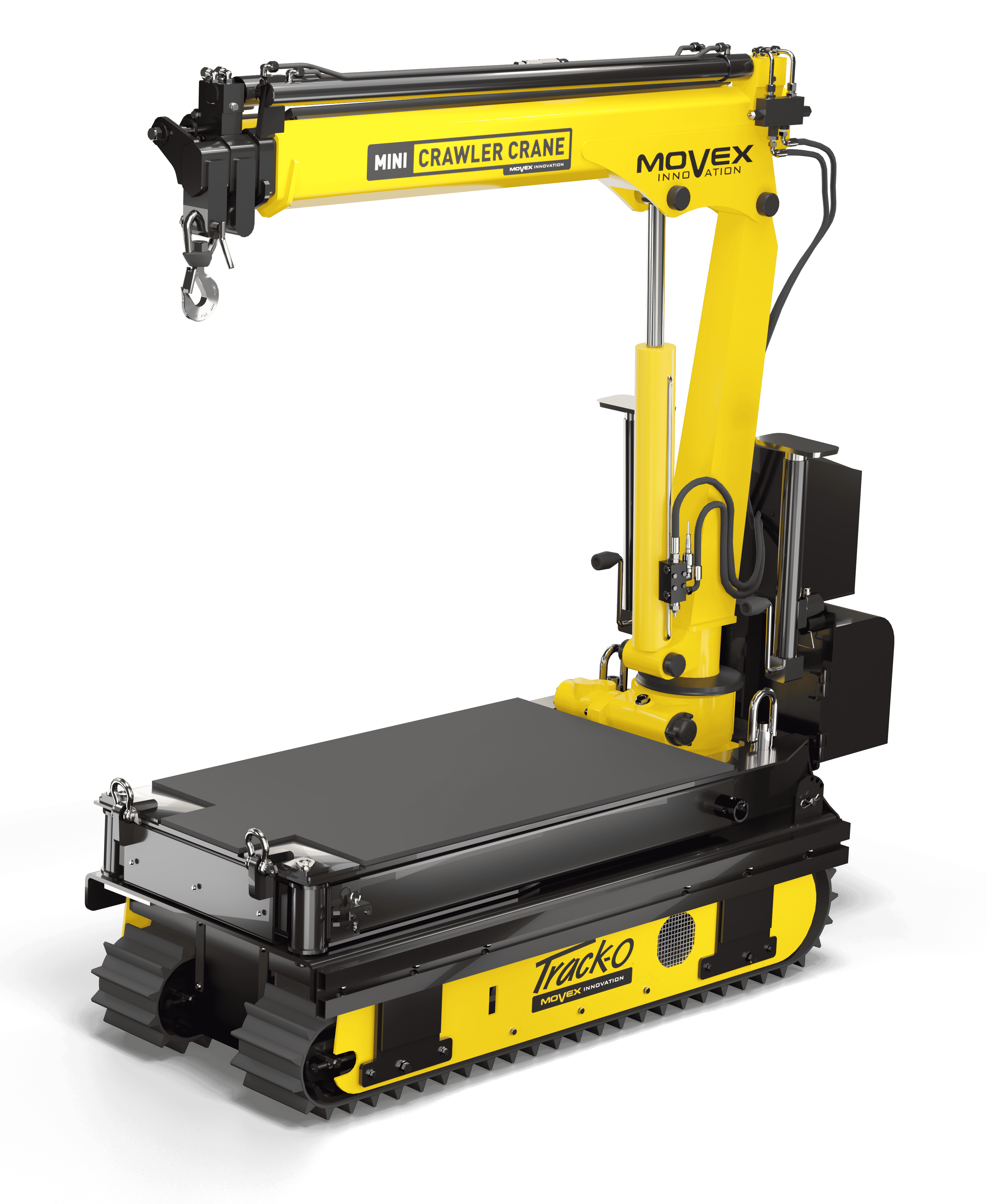

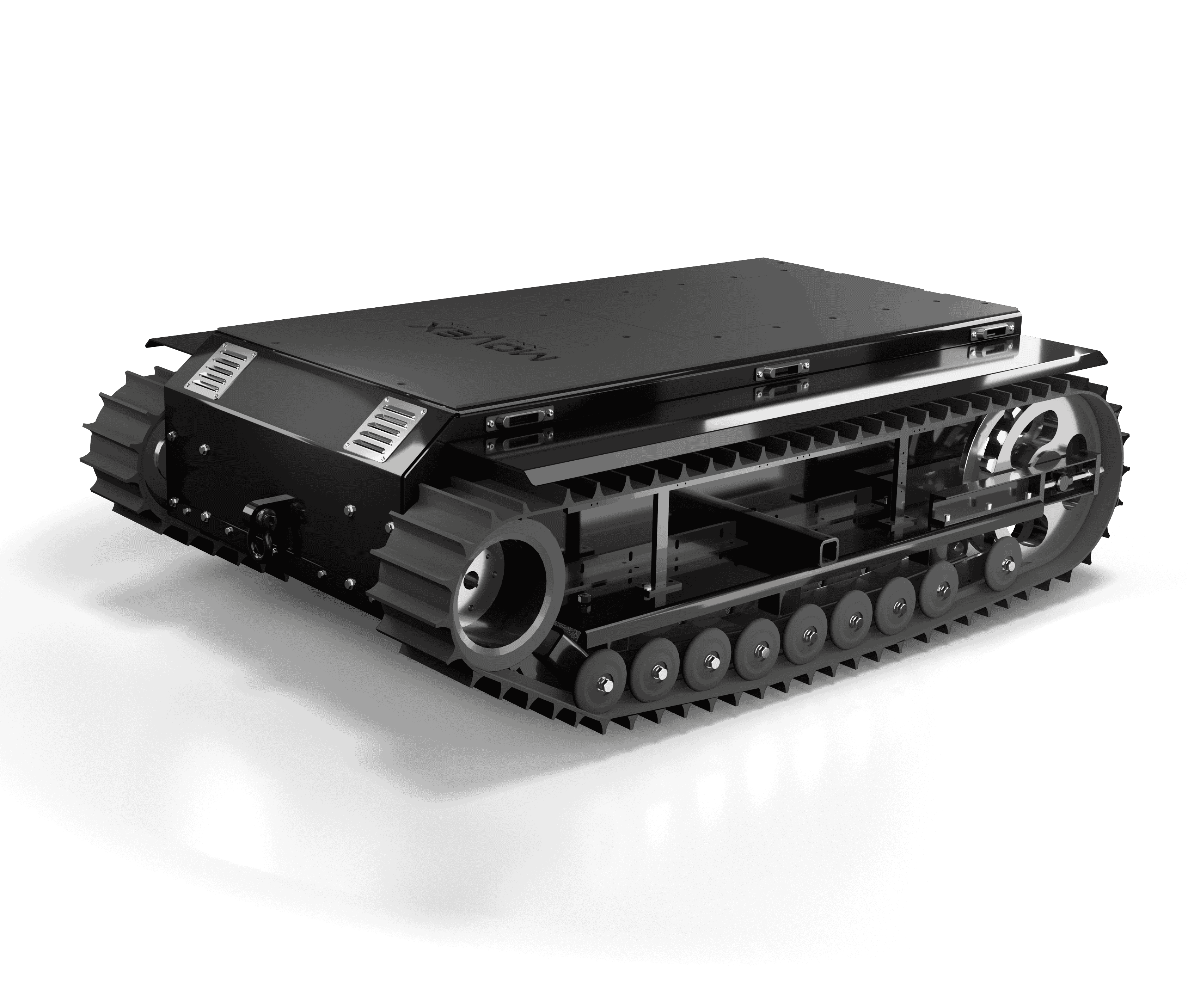

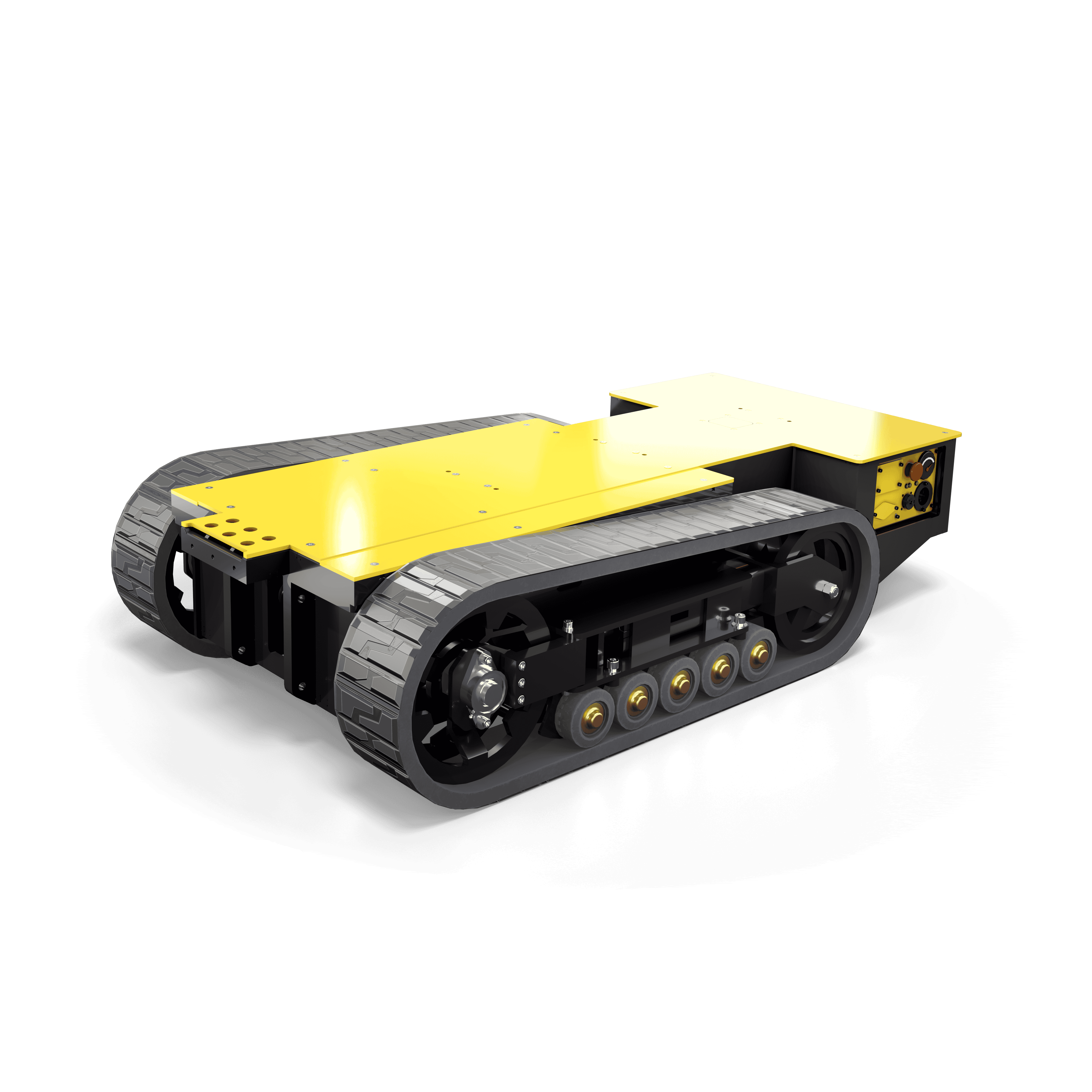

Modern and ultra-compact material handling equipment in construction is one of the easiest technologies businesses can implement to reduce the negative impacts of a tight labour market on operations.

Let’s explore how.

Catering to a new generation of workers

Manual labour has traditionally been the backbone of the construction industry. However, the reluctance of the younger generation to engage in strenuous physical labour is now very common. Given the choice between manual tools or technologically advanced equipment, most new construction workers will opt for the latter.

This preference for efficiency over exertion is where construction material handling machines step in. Ultra-compact, remote-controlled equipment can simplify material handling tasks that were traditionally done by only hand. Rather than struggle with moving materials from Point A to Point B, oftentimes in rugged, cumbersome or confined spaces, younger workers can now operate newer material handling equipment effortlessly, elevating their job satisfaction and increasing employee retention.

Better construction site health and safety

A case in point? Battery-powered construction material handling equipment, such as Movex Innovation’s mini dozer, allows for reduced crews, cutting down the required number of workers from four or five to just two, without compromising on productivity or safety

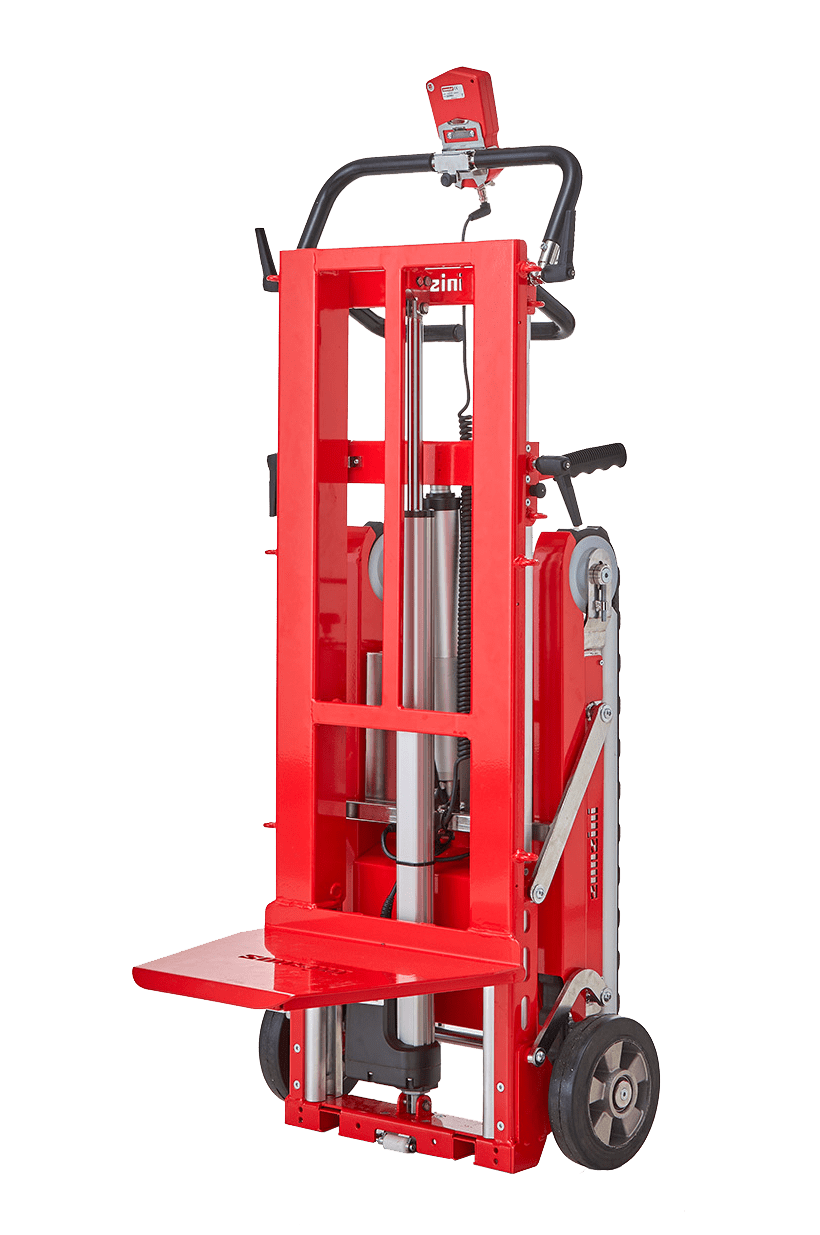

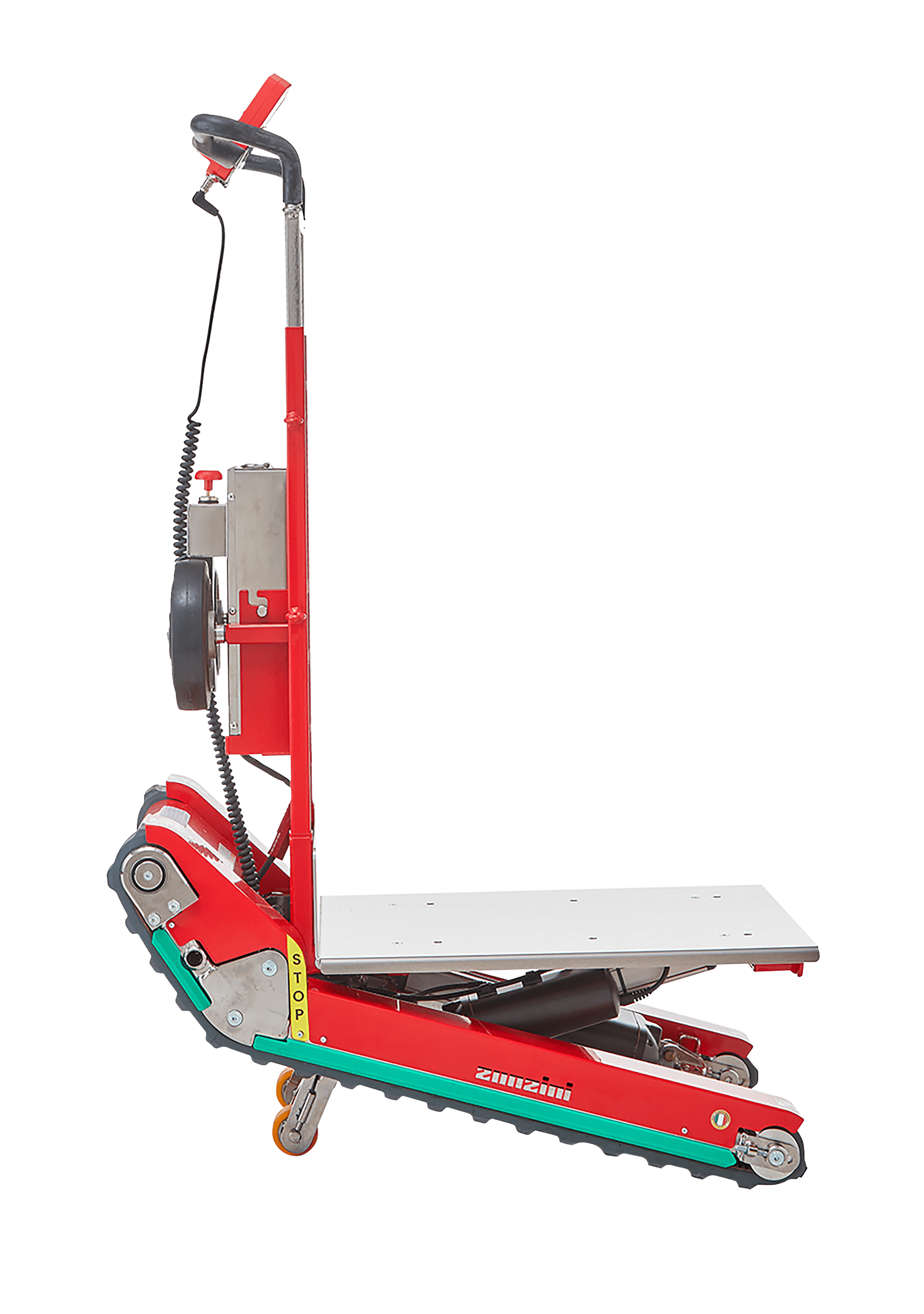

Reduced physical strain and exposure risks are other advantages of remote-controlled electric material handling equipment. Here is an example. In the past, workers struggled to move material up and down stairs, increasing the risk of immediate and long-term injuries. Now, with ultra-compact stair climbers, a fewer number of employees can haul loads where they need to go without compromising worker safety. Because contemporary tracked stair crawlers are increasingly electric, the staff is not exposed to airborne dust, fuel leaks, and toxic emissions.

Finally, while keeping employee well-being in check, construction companies can reduce sick days and prolonged leaves of absence due to workplace-related health issues and injuries.

High-performance equipment. Improved workplace conditions

The silent operation of battery-powered construction material handling machines is another feature that makes them more appealing than their diesel counterparts.

Their all-electric drive systems are not only environmentally friendly but also create a more pleasant and quiet work environment. This factor is significant when considering employee retention, as workers are always looking for better day-to-day working conditions.

Operational cost savings

Using electric material handling machines on construction sites also accelerates material handling efficiency and strengthens output capacity, even with less staff. Ultra-compact, remote-controlled material handling equipment streamlines operations, helping businesses to complete tasks faster and keep projects on schedule.

Moreover, the reduced need for large construction teams lessens the risk of delays and cost overruns, directly benefiting the project’s progress and financial viability.

In conclusion, construction material handling machines present a multifaceted solution to the current labour challenges in the construction industry. Their adoption is not just a matter of keeping pace with technological advances but a strategic investment in the future of construction, ensuring that projects can progress efficiently and safely, even as the nature of the industry’s workforce evolves

Would you like to explore some of Movex Innovation’s solutions for the construction sector? Check out our TT-66 tracked urban carrier, XC-30 all-terrain track carrier, and M-27 mini loader.