Ultra-compact material handling equipment New solutions to unique challenges in construction, mining, and utilities

Written by leonard | January 9th 2024

In today’s increasingly complex construction, mining, and utility sectors, efficiency, cost-savings, and workplace occupational health and safety are more important than ever. These industries face a wide range of material handling challenges, from navigating through narrow urban job sites, accelerating throughput, and ensuring worker safety to dealing with an aging workforce compounded by a tight labour market.

Unfortunately, standard large-sized material handling equipment, with its large footprints, often falls short when it comes to operating within the tight confines of rugged construction sites, the intricate tunnels of a mine, or the high-stakes operational zones of power grids.

The constraint is not merely spatial but also logistical, as the heavyweight machinery typically used in such industries can exacerbate issues of ground disruption and is often impractical or too expensive to be used in challenging or remote environments. In addition, industrial material handling equipment requires qualified personnel to operate it and can be complex to maintain. Finally, with fuel prices showing signs of coming down, many businesses are dealing with increased operational costs simply running their material handling equipment.

The rise of compact material handling equipment

In the face of these pressing challenges, several material handling equipment manufacturers have started developing more compact fuel-powered equipment and even electric industrial equipment powered by batteries.

These smaller units are definitely a step in the right direction, offering more maneuverability and versatility in confined spaces as well as generating less ground impact. Easier to operate and maintain than their predecessors, compact material handling equipment has been proven to improve productivity and operational efficiency.

However, compact industrial material handling equipment still presents several material handling challenges. For example, most machines are still too big to navigate through very tight and restricted spaces. Most have been designed for general-purpose use—and not the demanding tasks of very specific applications. Compact material handling equipment must still be operated on board by experienced staff. While some have become electric, many material handling machines are still run on gas. Until now, there was a jarring gap in material handling solutions for the construction, mining, and utility industries.

And that is where Movex Innovations steps in.

The business case for ultra-compact remote-controlled and battery-powered material handling equipment

Movex Innovation is ushering in a new era of ultra-compact material handling solutions that are powered by batteries and can be controlled remotely by operators.

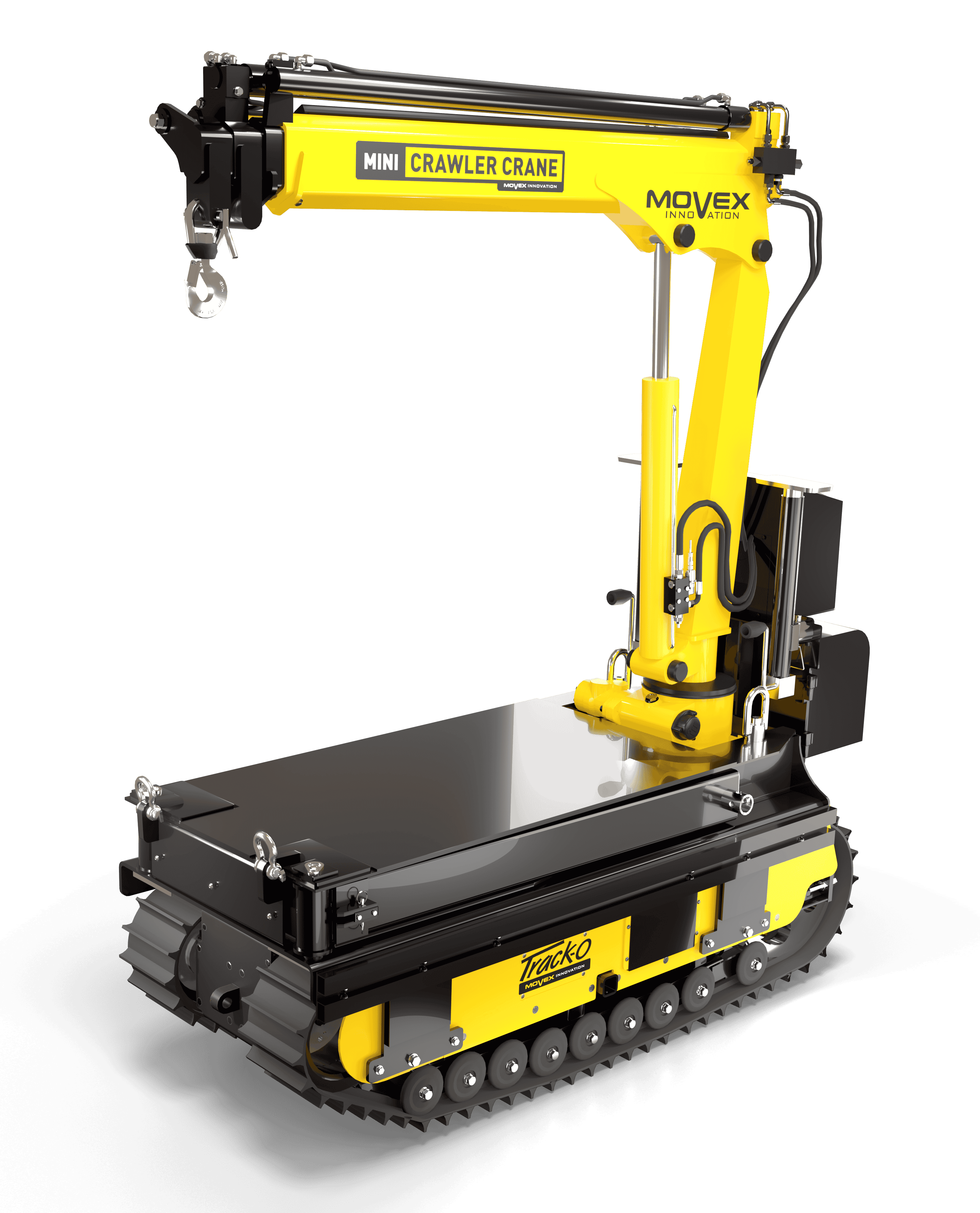

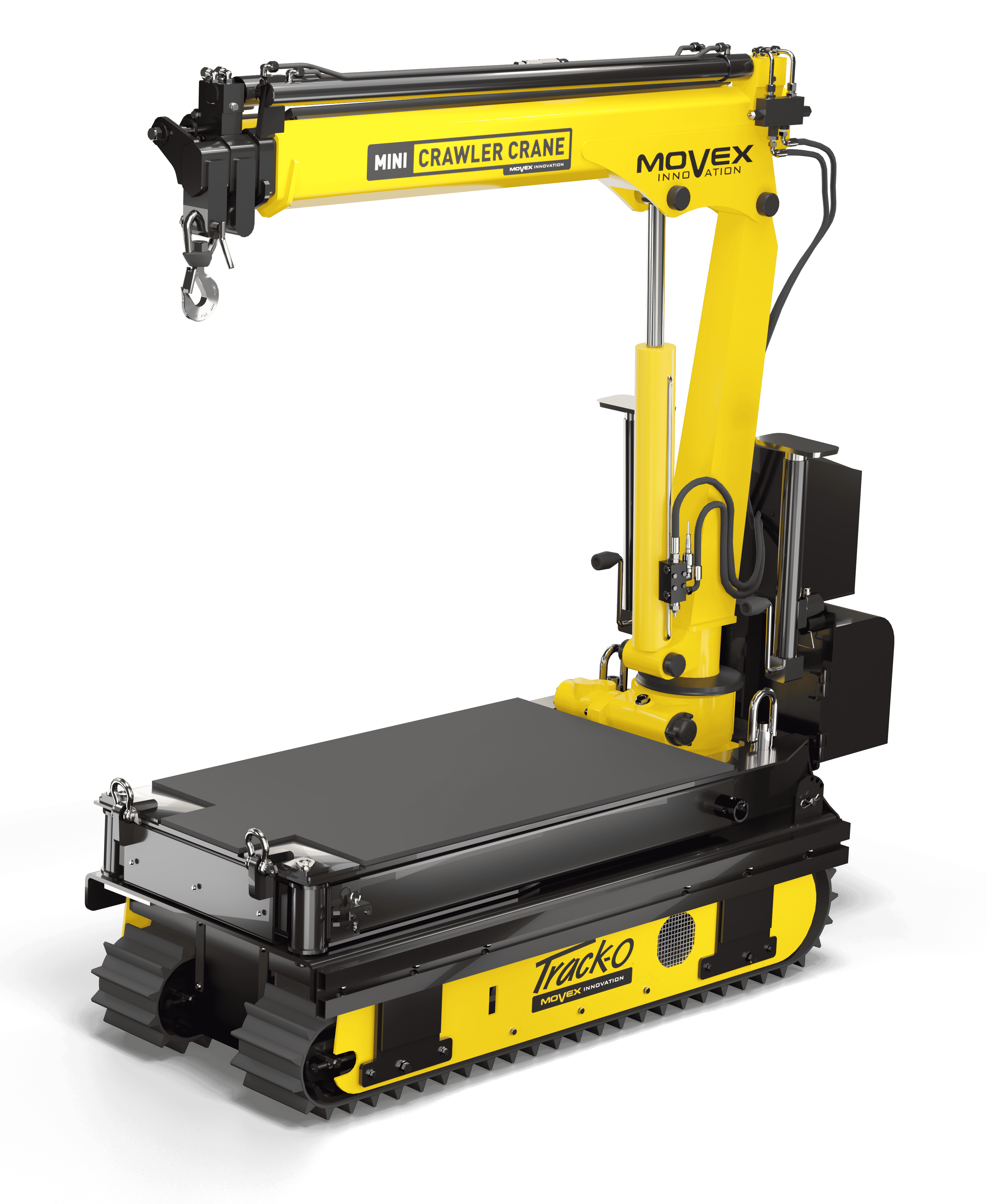

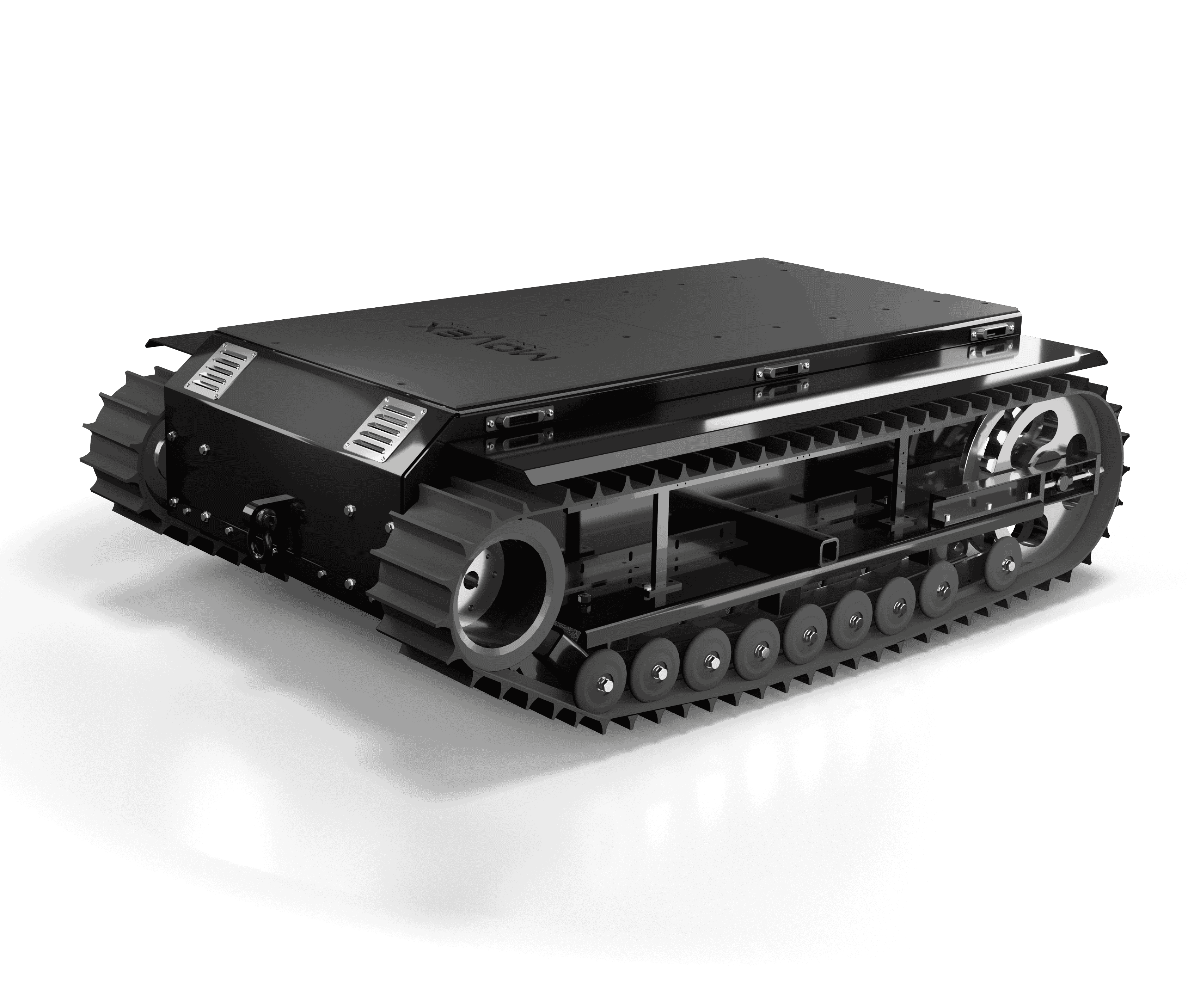

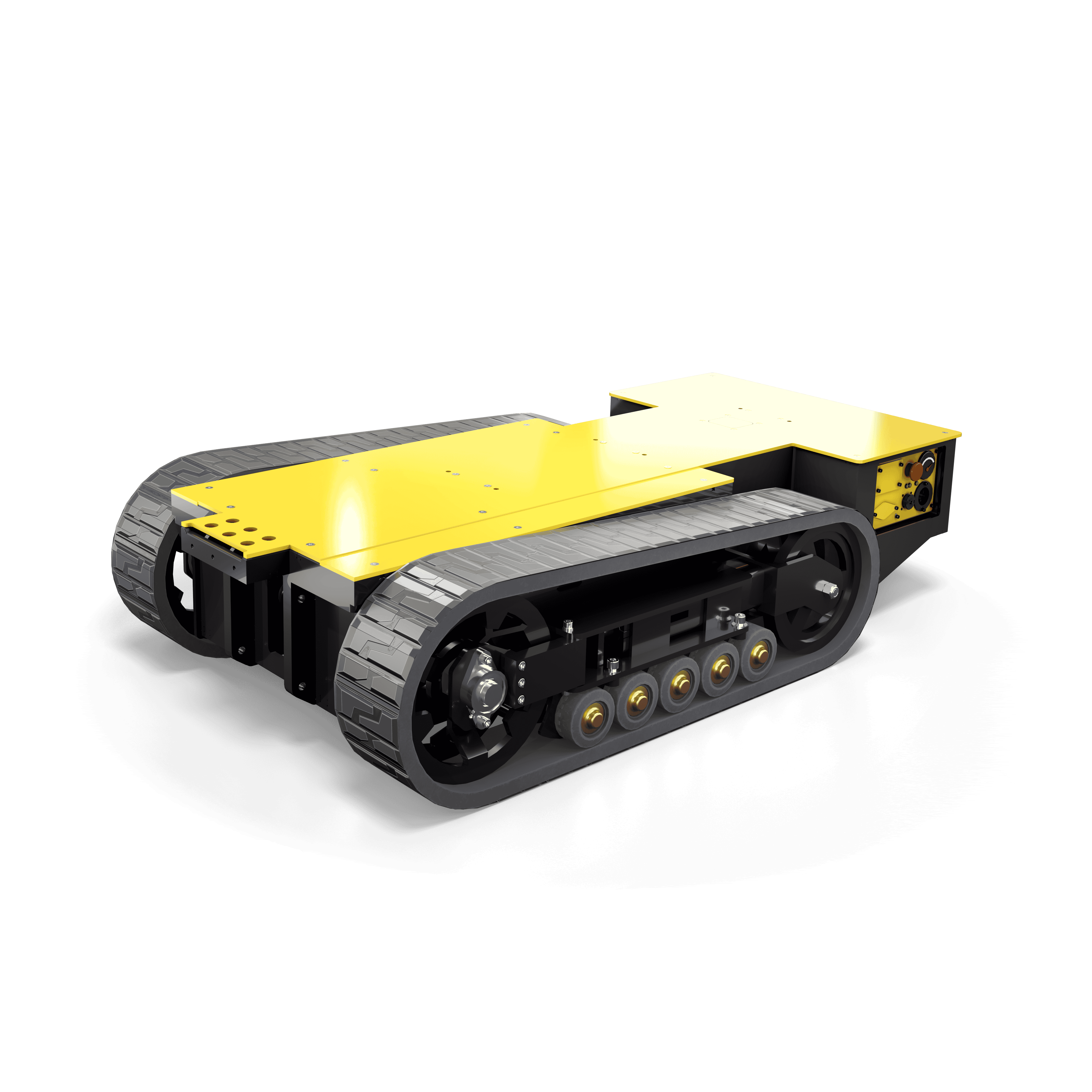

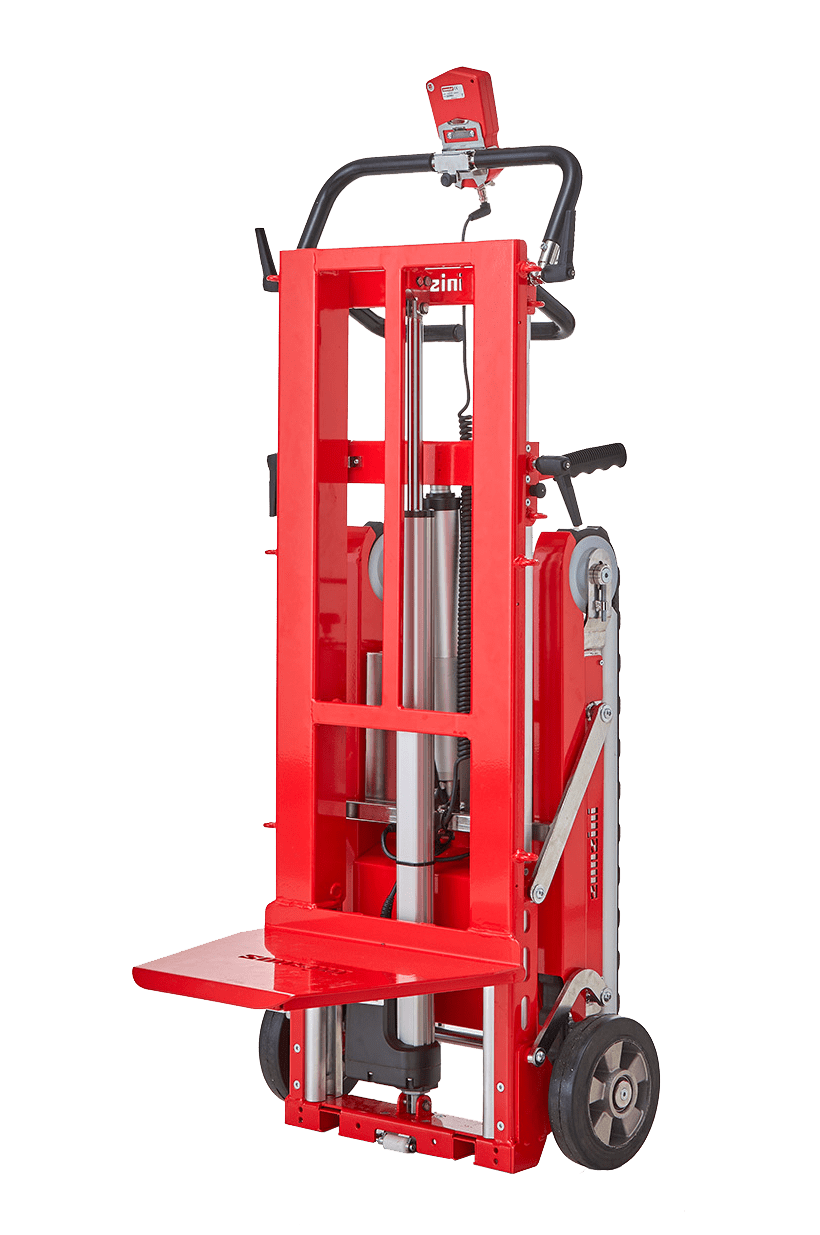

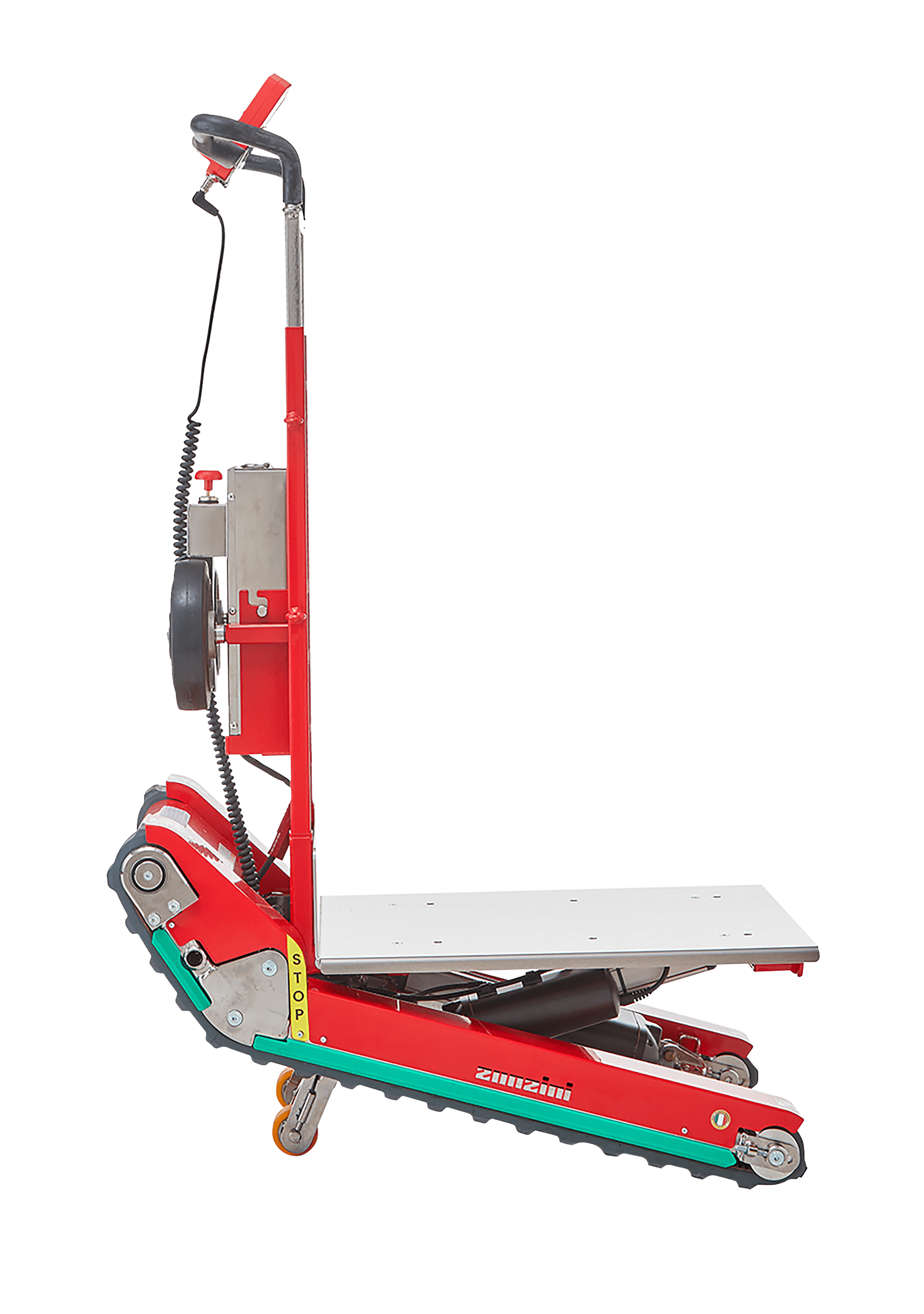

Our industrial material handling equipment, typically 30 inches wide, is designed to operate in spaces where traditional and legacy compact material handling equipment can’t. This ultra-compact dimension is not just a feature but a necessity for specific tasks, such as navigating narrow corridors or operating in very confined areas, which are very common in mining and construction. Developed to withstand harsh conditions, Movex Innovation’s ultra-compact electric industrial equipment can also be used for jobs in utility companies.

Here are just some of the ultra-compact material handling solutions Movex Innovations offers:

Besides being able to tackle material handling jobs in very constricted spaces, there are several other key benefits of Movex Innovations’ ultra-compact material handling equipment, including:

A complete range of material handling solutions: Movex Innovation offers stair climbers, urban carriers, mini loaders, all-terrain carriers, industrial carriers, and mini telescopic cranes

Battery-powered: Our electric material handling equipment helps businesses substantially reduce fuel costs and generate zero emissions or noise.

Remote-controlled: Easy to use, all of Movex Innovation’s material handling equipment improves worker health and safety by minimizing direct exposure to harsh terrains and hazardous conditions. Each material handling solution also requires less physical effort and fewer human resources to get a job done.

Versatile options: Each business has different material handling challenges. Movex Innovation provides standardized material handling equipment as well as customizable material handling solutions and accessories for different needs. Movex Innovation also offers equipment rental services for ad hoc requirements.

Engineering services: Taking on the biggest material handling challenges

To cater to customers with special material handling challenges, Movex Innovation’s engineering services enable clients to create a piece of equipment from scratch thanks to feasibility studies, conceptual and detailed engineering, and manufacturing.

Our initial forays into ultra-customized, ultra-compact material handling equipment design started when we were first approached by a major aluminum smelter to develop a mini loader with an exceptionally low profile that was capable of maneuvering under electrolytic cells and remove alumina.

Next, a large electrical distribution company, Hydro-Québec, asked us to develop an all-terrain, ultra-compact pole-mounted transformer carrier and installation vehicle. At the time, there was no solution on the market to enable them to carry out maintenance in a back lot. You can read more about our work with Hydro-Québec here.

Future directions in material handling equipment

As the material handling industry evolves, several key trends have emerged, shaping the future of operations in construction, mining, and utilities. These trends reflect each industry’s response to material handling challenges and the shift towards more efficient, sustainable, and flexible equipment.

Movex Innovation, with its finger on the pulse of these developments, has positioned its suite of material handling solutions not just to meet these trends but to be at the forefront of them, future-proofing ultra-compact equipment for all types of material handling applications.

Modular and scalable solutions

The demand for modular solutions reflects the clients’ need for customization and flexibility. Modular systems allow for rapid assembly, reconfiguration, and scalability to meet the changing demands of businesses. Recognizing this, Movex Innovation offers customizable equipment and engineering services so that any company can benefit from our ultra-compact material handling solutions and overcome their distinct challenges.

Ergonomic and safety-first designs

Enhancing ergonomics and safety in material handling equipment design improves worker well-being, reducing workers’ physical strain and risks—and boosting compliance of safety protocols based on industry standards. All of Movex Innovation’s material handling equipment are remote-controlled and highly ergonomic, safeguarding teams from hazards and injuries.

Green and sustainable practices

Each industry’s pivot towards green and sustainable practices is driven by the imperative to minimize its environmental impact. That’s why Movex Innovation’s electric industrial equipment is battery-operated and produces zero emissions. Rather than relying on non-renewable energy sources, like fuel, and leveraging the performance of electricity as a renewable energy source, Movex Innovations equipment is indeed a greener alternative.

Robotics

Automated systems, like automated guided vehicles (AGVs), are revolutionizing the way materials are transported within facilities, bringing about reductions in labour costs and human error while enhancing speed and accuracy. Movex Innovation’s equipment is often referred to as material handling robots—not because they are entirely automated but because workers can carry out material handling tasks at a distance with remote control capabilities.

In sum, Movex International’s ground ultra-compact, electric material handling solutions for the construction, mining, utility, and many other industries are continually being adapted to unique material handling challenges with innovative, ultra-compact and high-performance equipment that goes where others cannot tread.

Interested in learning more about how Movex Innovation can support your business?

Read our latest articles