Customer Story - Hydro-Québec

Written by leonard | November 27th 2023

Hydro-Québec snapshot

Hydro-Québec (HQ) is a public corporation that has produced, transported and distributed electricity since 1944. This Québec flagship company has more than sixty hydroelectric power stations, making it one of the world’s most important producers of hydroelectricity.

In fact, they generate almost 100% of their electricity with the force of water. In addition to power generation, they operate the largest transmission grid in North America. It extends over more than 21,000 miles! Hydro-Québec also distributes electricity directly to their customers. Their distribution lines stretch over more than 162,000 miles!

Finally, Hydro-Québec has an important research and development department that allows them to be at the forefront of technology. With so much innovation in their DNA, Hydro-Québec and Movex Innovation have teamed up to develop an innovative solution that significantly improved the health and safety of their linemen.

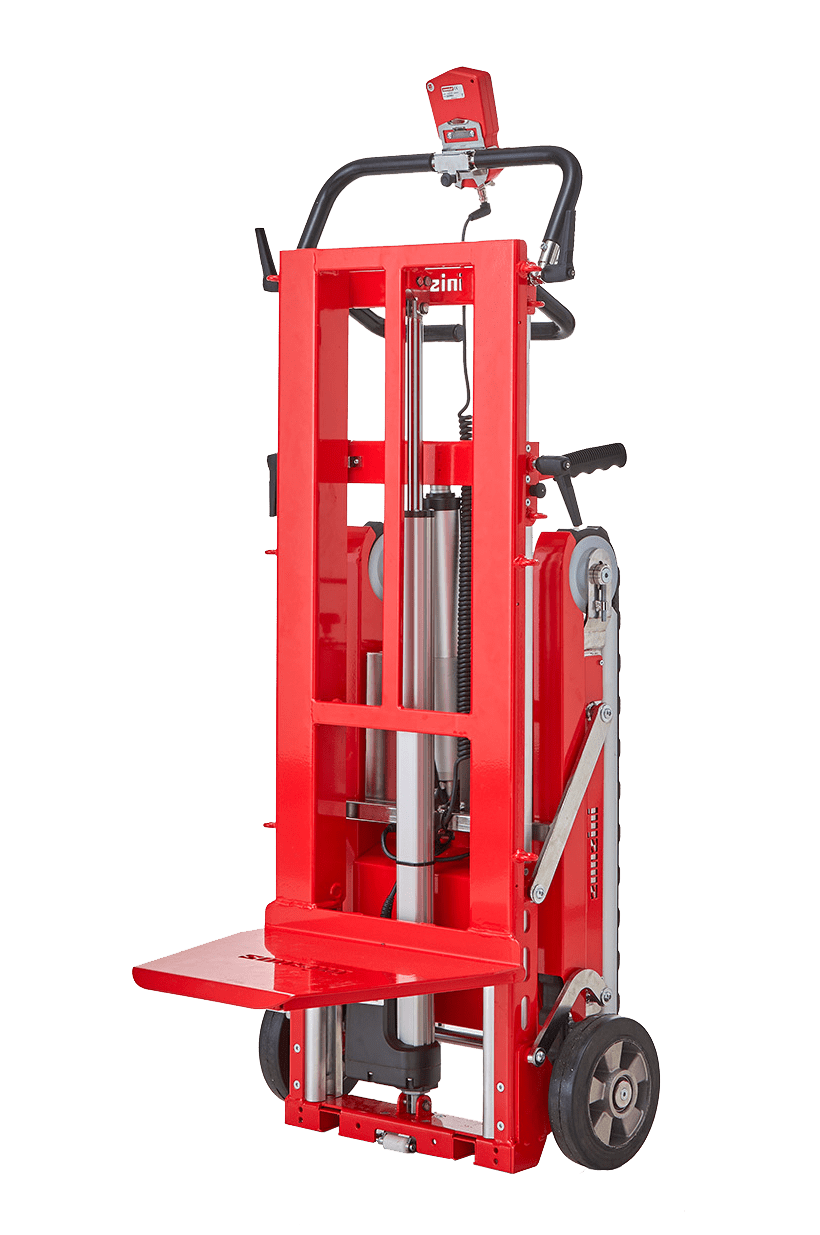

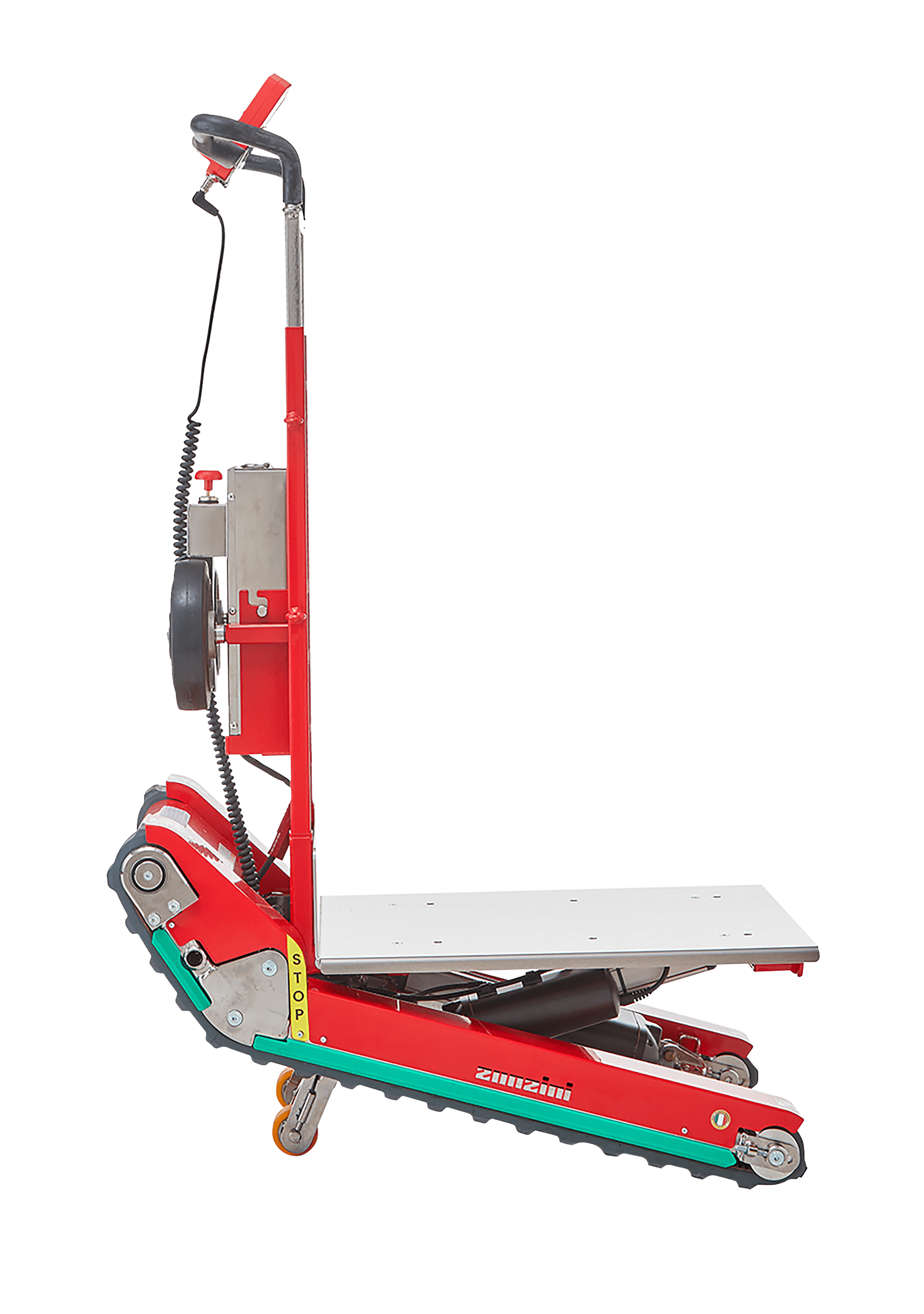

We have then developed the Cross-Country Utility, a pole-mounted transformer carrier and installation device. After purchasing the first unit in 2009, Hydro-Quebec realized how essential the equipment was for their backyard work and increased their fleet to more than 70 units today.

Challenges

With a distribution network of this size, it frequently happens that transformers are hard to reach. Typically, the maintenance team arrives on the job and performs the grid restoration and maintenance with a bucket truck. This solution works well only when the transformers are easily accessible from a street.

Before our collaboration, no equipment allowed their linemen to do back-lot maintenance. It is hard to imagine a bucket truck going into a backyard. The backyard would be hard to reach, and landscaping would be damaged. Hydro-Québec needed compact equipment that would enable them to go through a 30-inch-wide gate and a solution that would allow them to bring their equipment without damaging their client’s landscape.

This is not the only reason Hydro-Québec used our remote-controlled vehicle. The health and safety of their employees were a genuine concern for the company. It was through their standards and methods advisor that the project scope was defined and presented to the HQ management team.

Solution

The Cross-Country Utility is used primarily for back lot transformer replacement. It is used for routine maintenance, restoration maintenance, new grid development and distribution network re-engineering. Moreover, the frequency of use is based on the situations mentioned above.

Example

A violent storm breaks, and a branch falls on the electrical transformer located in a back yard, causing an electrical outage for 6 000 customers. A Hydro-Québec maintenance team reacts quickly to change the broken transformer for a new one. They can easily access the back lot with their compact Cross-Country Utility. In addition, they will not damage the customer’s back yard, will not disturb the neighbourhood, and they will get the job done safely.

Before having the Cross-Country Utility in their fleet, the maintenance team in the distribution department had many problems to address.

First, they had difficulty gathering the equipment needed for maintenance work in the backyard or hard-to-reach terrain. Then they did not always have generators for their power tools. Finally, they had to load the equipment needed for the job separately into multiple transport trucks. This often resulted in significant oversights, which increased the time needed to complete the job.

Our electric all-terrain vehicle was therefore designed to solve these three problems. The Cross-Country Utility enables linemen to move heavy equipment like a transformer into narrow places, carry all the tools needed for a job, and allows linemen to use power tools with the machine’s built-in inverter charger.

Furthermore, according to the Fleet manager, if Hydro-Québec had not used the Cross-Country Utility, there would have been an increased risk of injury when transporting the equipment, and operating time would have been longer. With our equipment, they can carry transformers over 1800 lb on rough terrain.

In addition, they can safely lift the transformer to its spot with its hoist system and capstan brake. This dramatically reduces the physical effort required to install an overhead transformer. Also, the capstan brake prevents the transformer from falling when the lineman lets the rope go.

“Everything on the market has been tested. Various equipment that was non-compliant in terms of capacity or load was modified and used before the development of the Cross-Country Utility. It was developed to meet the needs by bringing together all the equipment in a single product, reducing handling, and respecting the standards in terms of mechanical and electrical capacities”. —Claude

Results

Although it was not the primary goal and it is difficult to quantify, the Cross-Country Utility saved time and money for the organization. Hydro-Québec meets its objective to have equipment that meets safety standards for its workers while maximizing ergonomics. Using electric equipment like ours contributes to Hydro-Québec’s ecological brand image. Finally, our product’s electrical aspect allows linemen to work at night without disturbing the neighbourhood. This is also explained because an electric motor is quieter than a gasoline engine.

The fleet manager says they were able to generate cost savings associated with maintenance work. Using electric equipment compared to a piece of gasoline-powered equipment increased reliability and reduced operation and maintenance costs. They also optimized labour management by sending one less employee on back-lot maintenance work.

Contact us for more information!

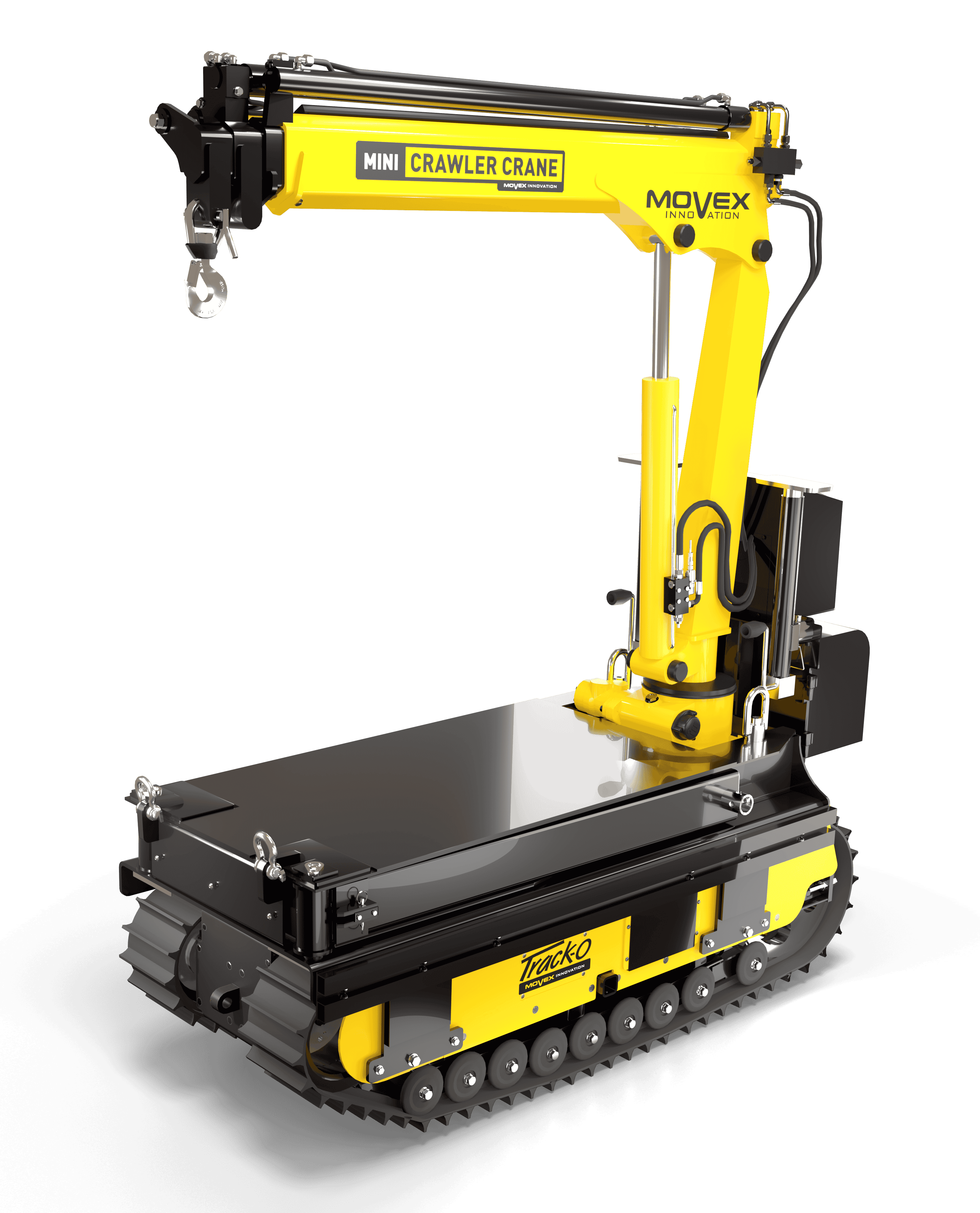

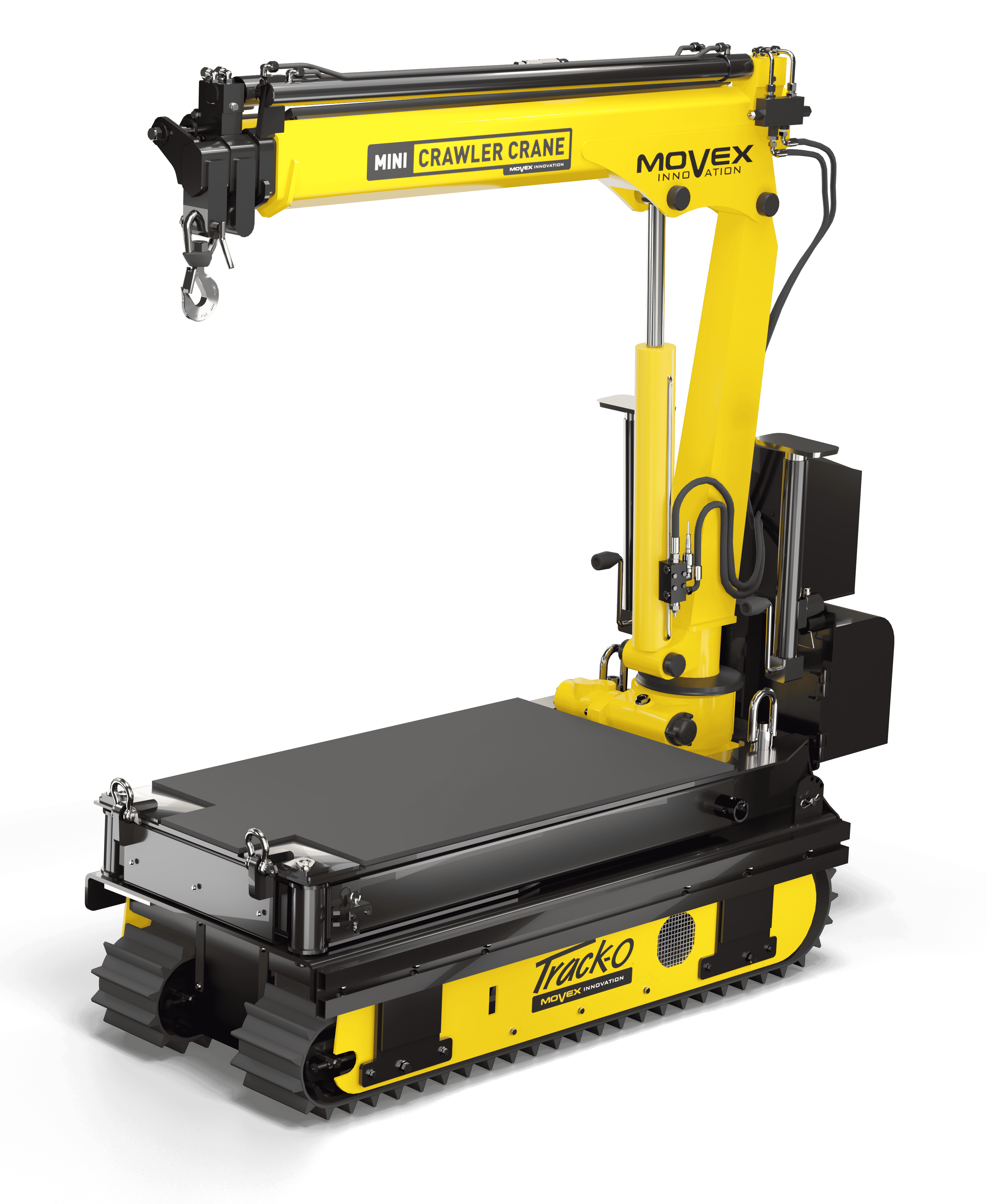

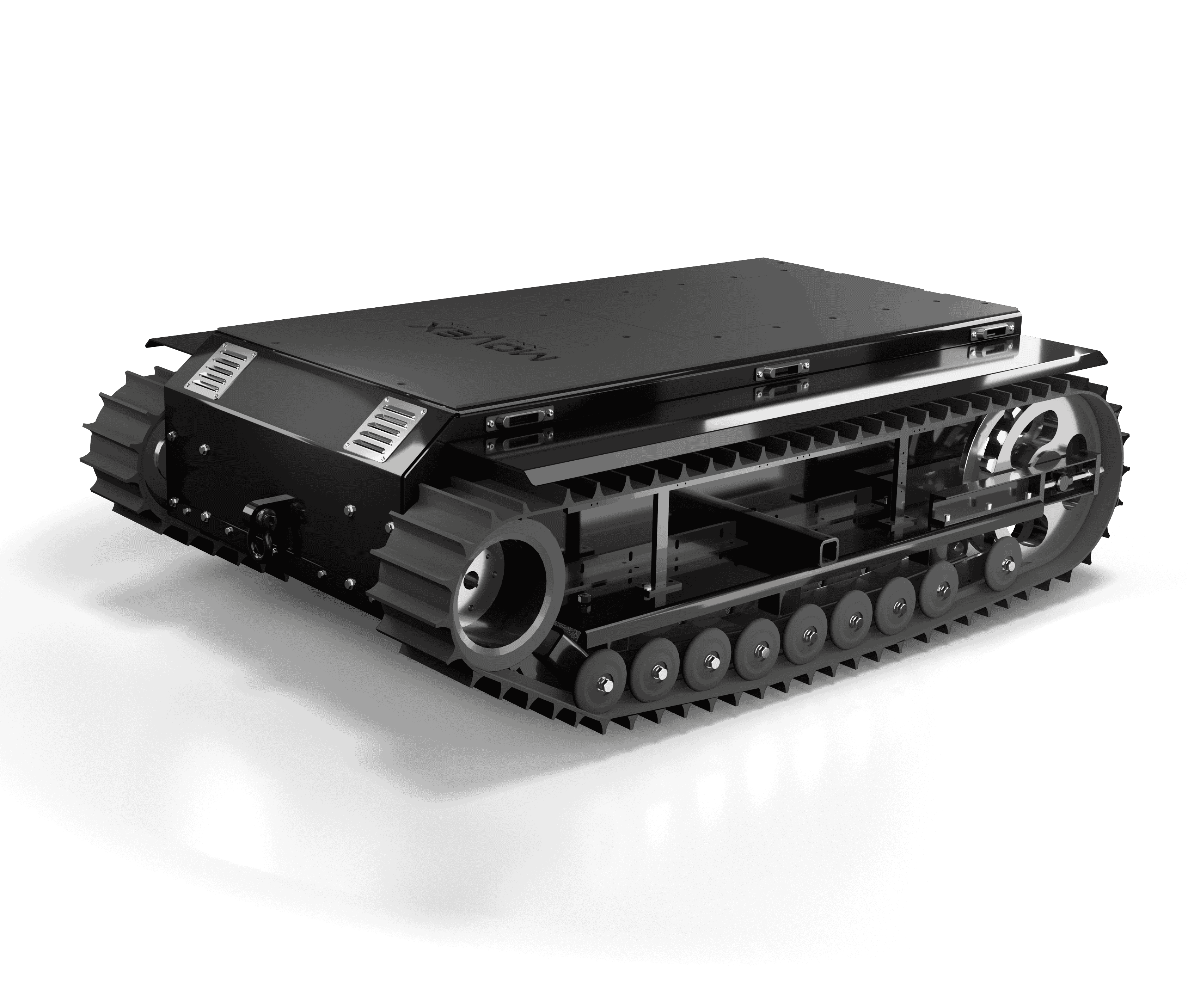

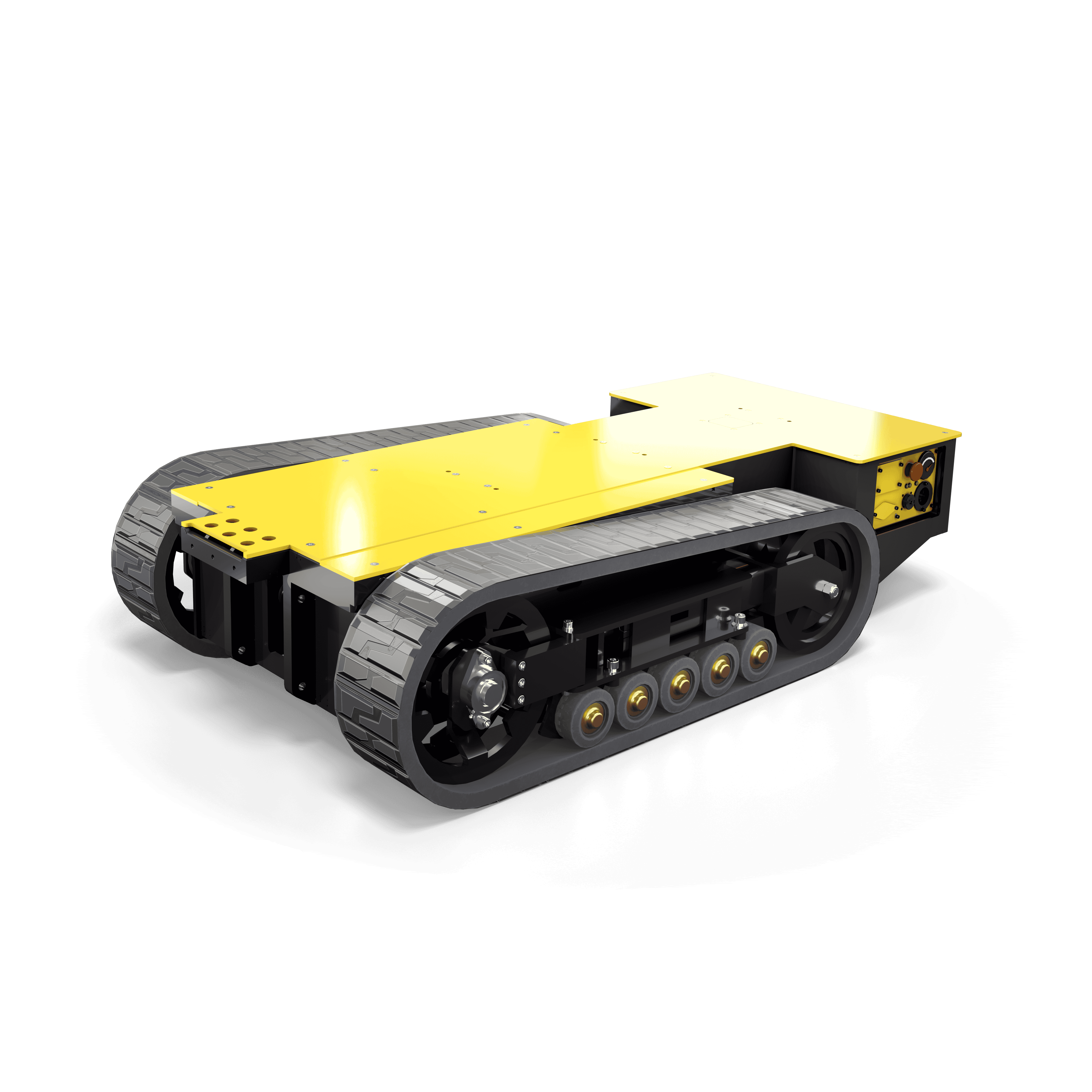

As demonstrated, the Cross-Country Utility is a perfect piece of equipment to transport and install overhead transformers. But what about pad-mounted transformers or underground transformers? Well, we also have the equipment for that.

For more information, do not hesitate to contact our commercial director responsible for developing the electric utility market.