Tips for Finding the Right Material Handling Equipment

Written by William Nicholls | September 15th 2025

The first time Jake stepped onto the site, he knew the job was going to be hell. Narrow hallways. Uneven terrain. Tight delivery windows. And a whole lot of weight to move.

His workers had been making do with outdated material handling equipment for months, burning out their backs, wasting hours on workaround solutions, and cursing every time a machine stalled mid-transfer. It wasn’t that they didn’t care about efficiency. They simply didn’t know there were better options available.

Finding the right material handling equipment isn’t about picking the biggest machine or the flashiest tech. It’s about choosing material handling solutions that match the realities of your work. The stakes? Time, safety, and money.

What is material handling equipment?

Material handling equipment is the backbone of any job site that deals with physical goods. It’s the gear that moves, stores, protects, and controls everything from bulk materials to neatly packaged boxes. Whether you’re hauling sacks of cement up a flight of stairs, shifting pallets in a warehouse, or transferring components across a factory floor, material handling equipment is what keeps things moving.

But don’t picture only forklifts and pallet jacks. Material handling solutions encompass a wide range of machines, including stair-climbing dollies, compact dozers, conveyors, cranes, and automated storage systems. These tools are designed to handle various types of loads, such as loose aggregates, oversized equipment, and standard shipping crates.

You’ll find material handling solutions everywhere: mining operations carving through bedrock, construction crews pouring concrete on tight urban lots, logistics teams racing against the clock in last-mile delivery hubs, and manufacturers keeping production lines humming.

In every case, the right material handling equipment makes the difference between chaos and control.

Main categories of material handling equipment

Not all jobs call for the same kind of muscle. Choosing the right material handling equipment starts with understanding what’s out there and how each category fits into the real demands of your operation. Whether you’re stockpiling parts, moving gravel by the ton, or navigating a tight basement with a load of concrete, there’s a tool built for it. Here’s a breakdown of the main types.

Storage and handling equipment

This is your staging ground: the racks, shelves, stacking frames, bins, and drawers that hold materials until they’re needed. If you manage long-term inventory or a temporary holding of materials, this type of material handling equipment keeps things organized and accessible.

Bulk material handling equipment

When you’re dealing with loose materials like ore, coal, gravel, or grain, you need more than brute force; you need flow. This category includes conveyors, hoppers, silos, and reclaimers that are built to keep heavy, granular loads moving smoothly through your operation.

Industrial trucks

From forklifts and pallet jacks to carts and lift trucks, these are the go-to machines for moving materials across short distances, particularly when flexibility and quick maneuvering are key. If it needs to roll, pivot, or lift in a hurry, industrial trucks are ideal.

Engineered systems

High-tech, high-efficiency. These automated systems, like robotic arms, conveyors, AS/RS (automated storage/retrieval systems), are designed for speed, scale, and precision. Often integrated with digital control platforms, they’re built for operations where throughput and accuracy can’t be compromised.

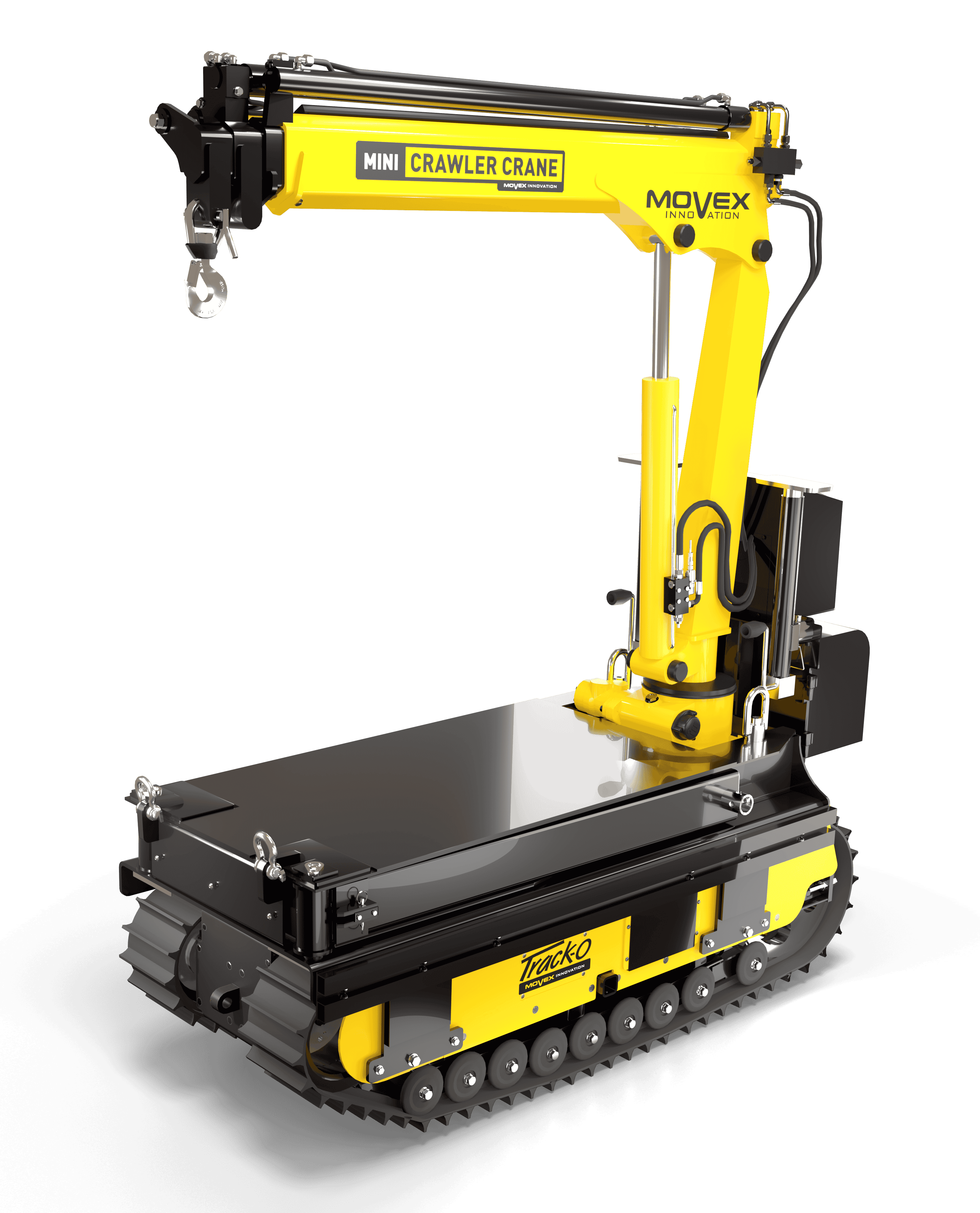

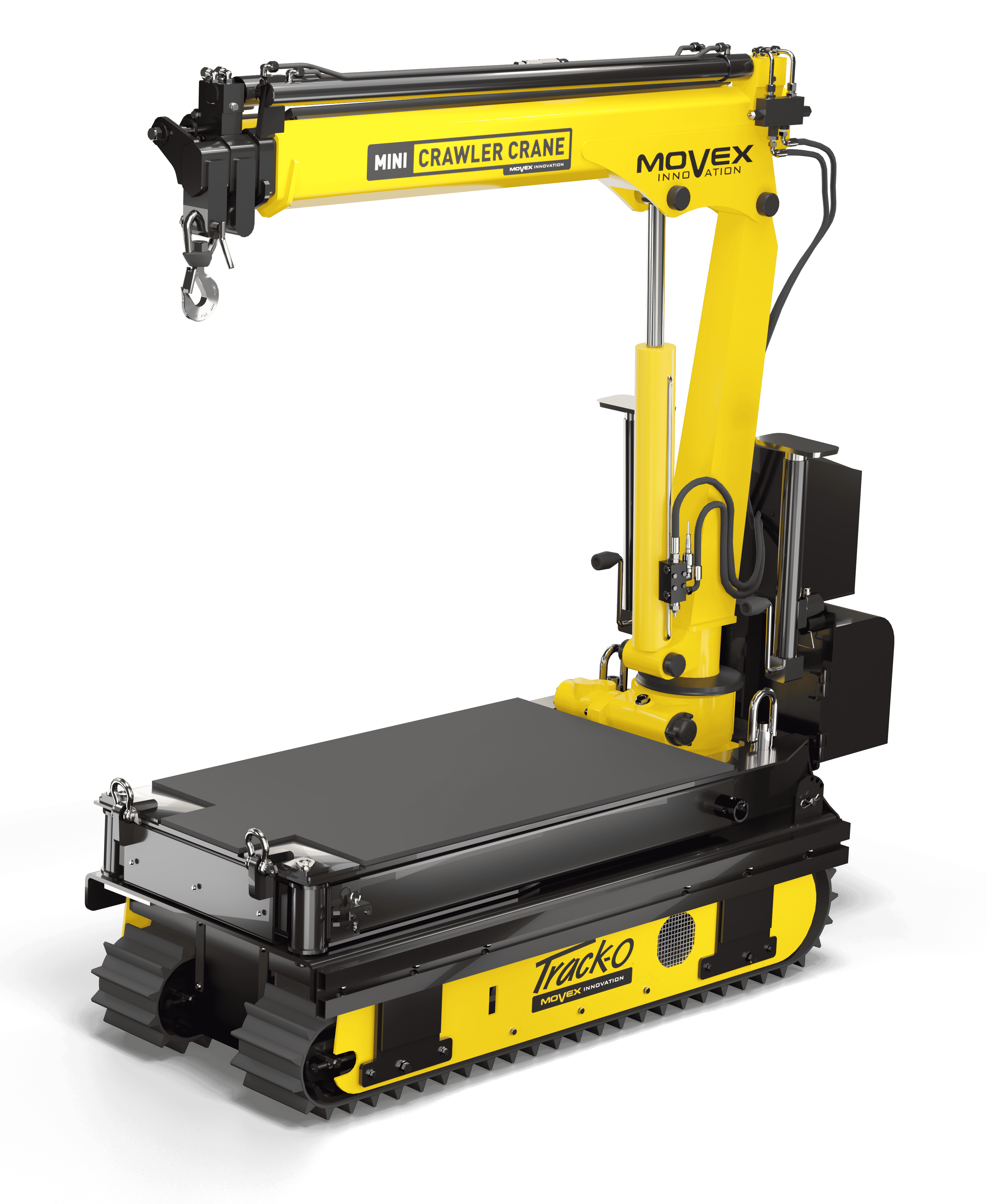

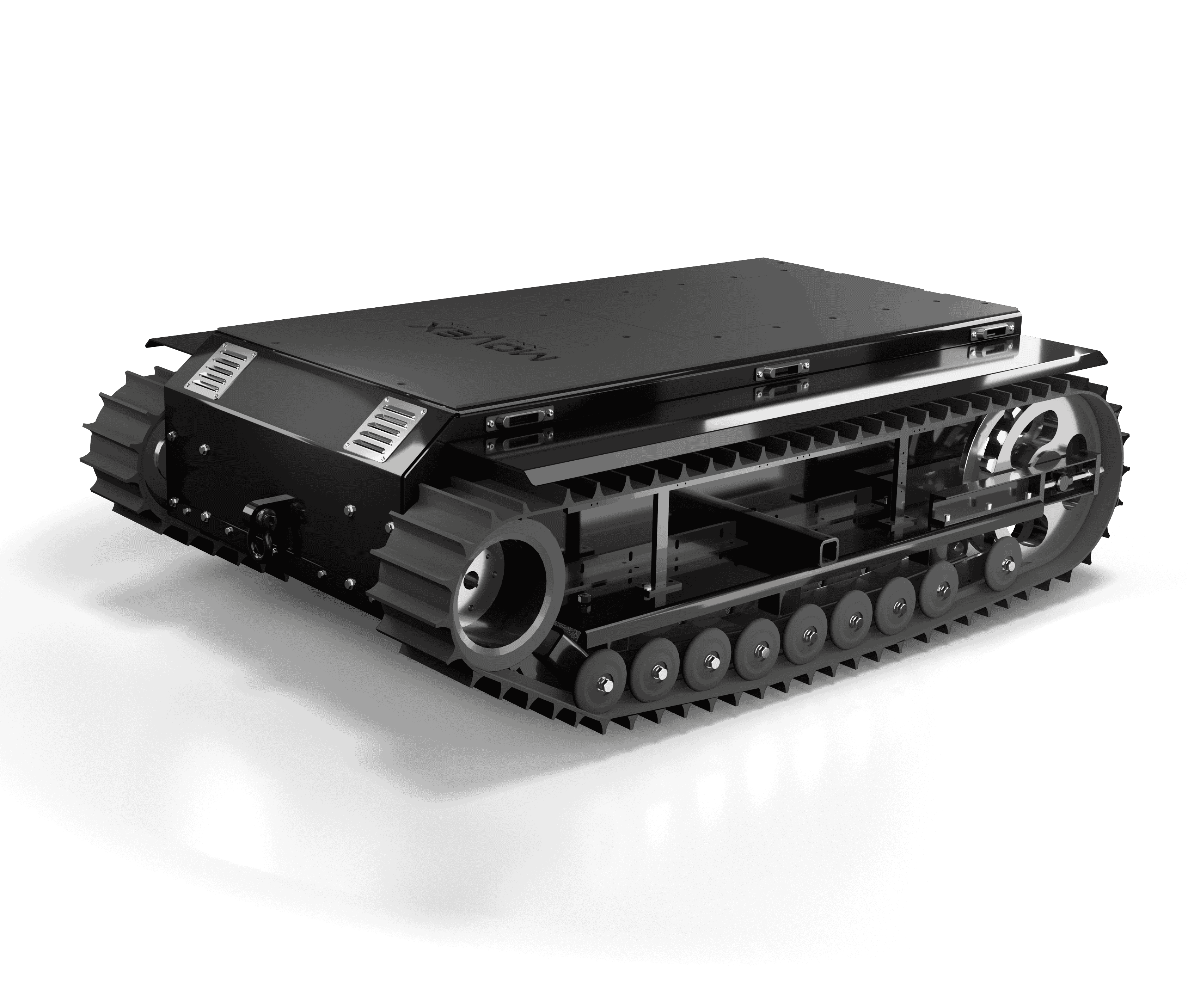

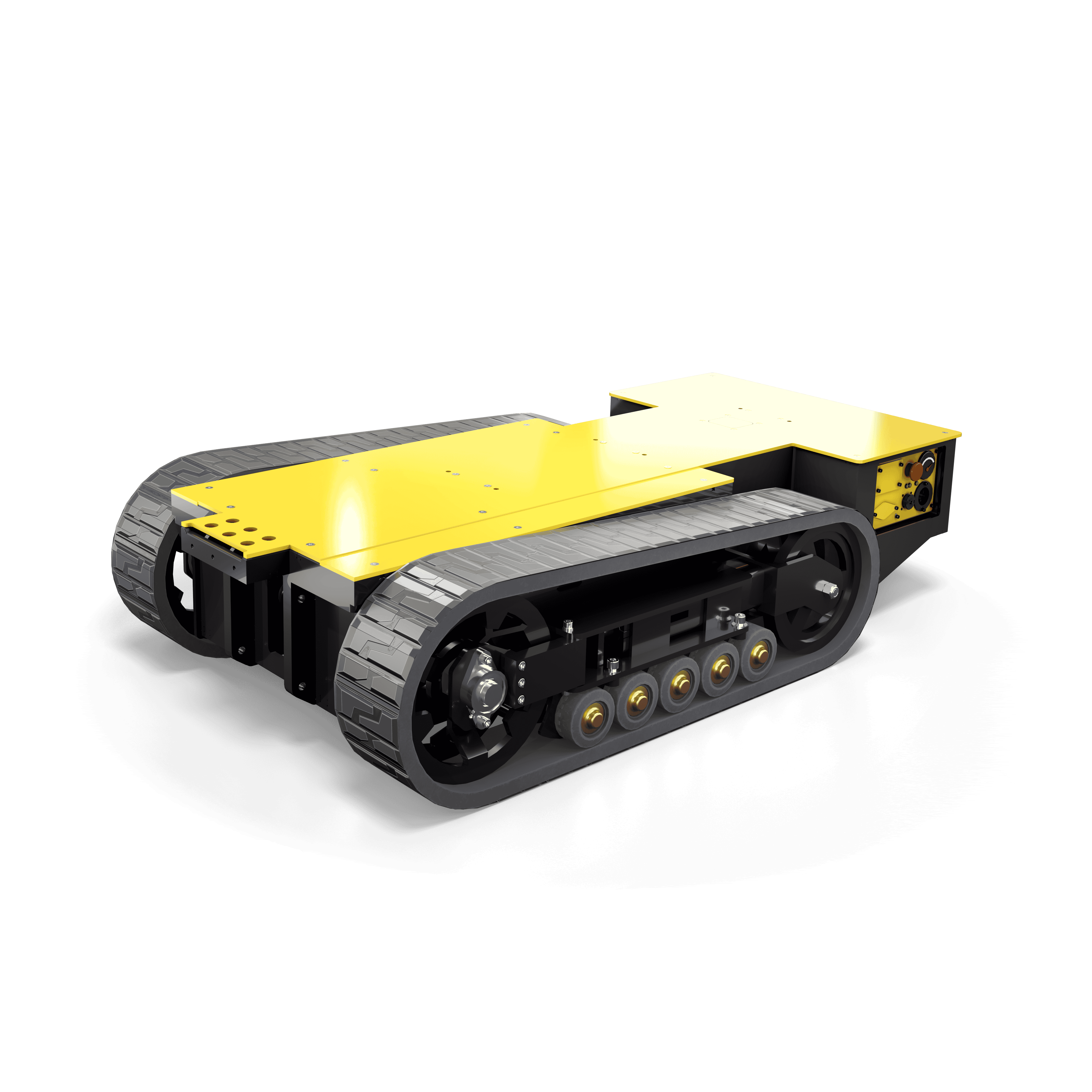

Specialty equipment

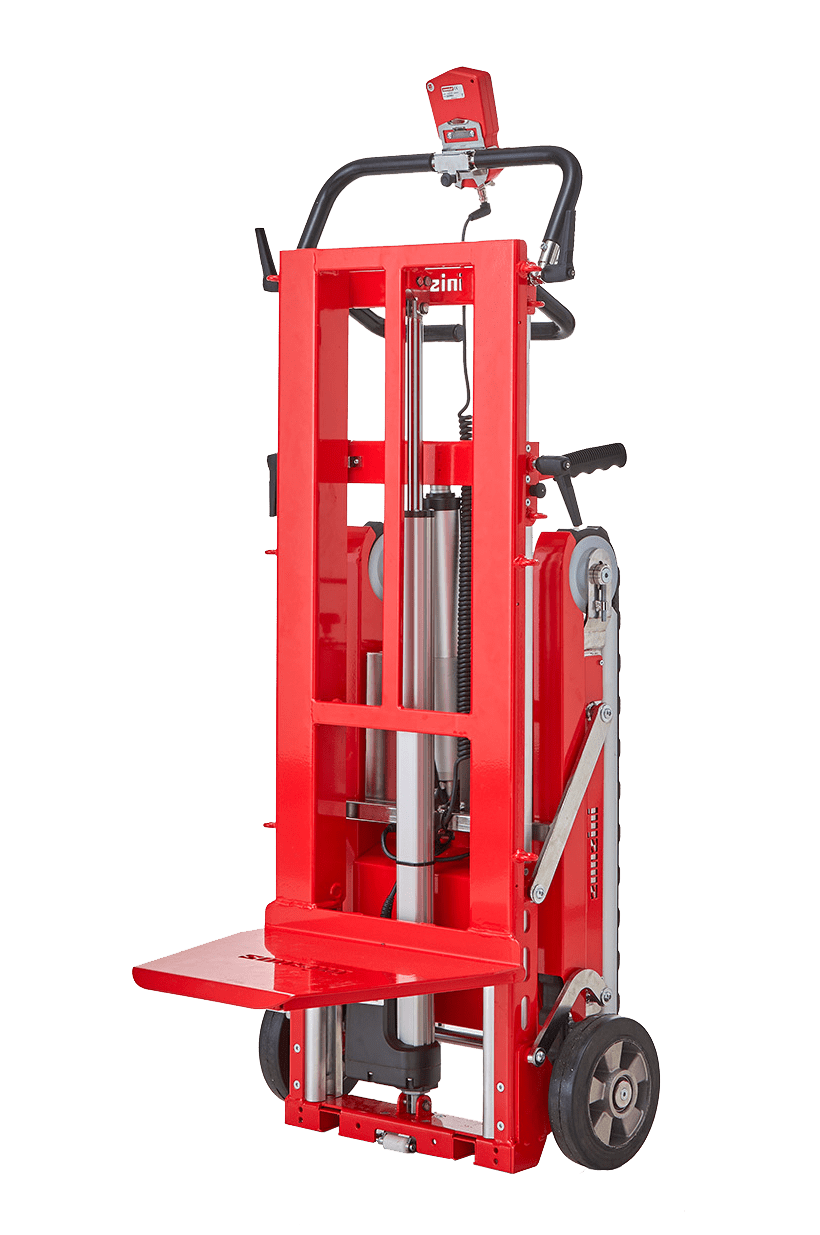

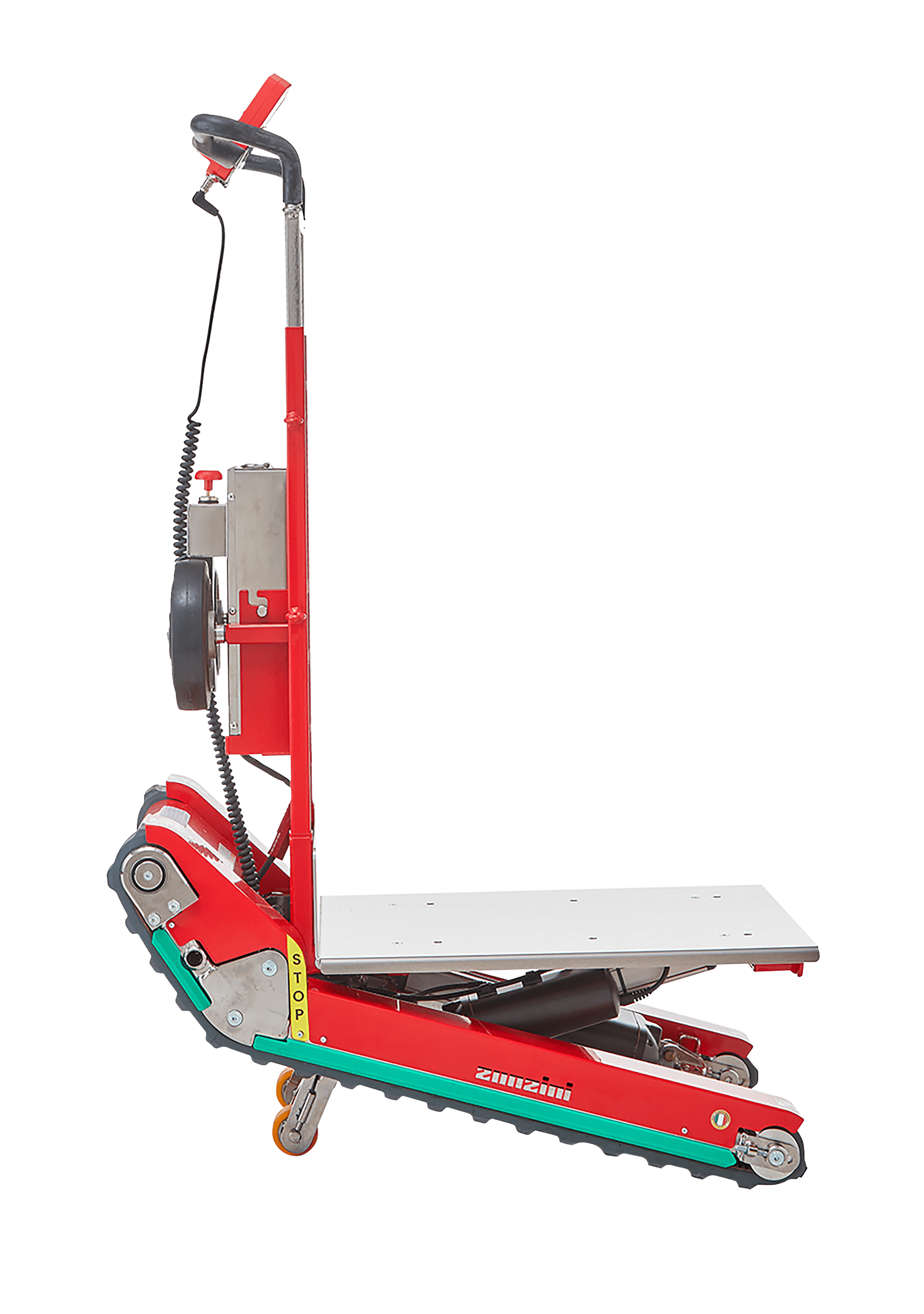

Some jobs fall outside the playbook. Tight stairwells. Cramped mechanical rooms. Uneven construction sites. That’s where specialty equipment, such as stair climbers, tracked carriers, and ultra-compact mini-dozers, comes in—material handling solutions like what Movex Innovation designs for teams that need to move heavy loads through challenging terrain.

Interested in learning more about Movex Innovation?

Key features to consider when choosing material handling equipment

The right material handling equipment is more than what looks good on paper. You need to consider how it holds up in the field.

Before signing off on your next purchase or rental, take a hard look at the features that matter most to your day-to-day reality.

Here’s what experienced material handling managers weigh when making the call.

Load capacity and weight handling

Start with the numbers. If the equipment can’t safely handle your heaviest load, it’s a non-starter. Don’t just look at average weights; factor in your worst-case scenario. At the same time, don’t design around rare exceptions. Choose a product that performs reliably for the majority of your needs. Remember, it’s not magic—it’s a tool. And like any tool, it has its limits.

Terrain type

Flat warehouse floors are one thing. Muddy construction sites, uneven gravel, or steep stairs are another. Your material handling solution needs to be compatible with the environments it’s working in: indoor or outdoor, smooth or rugged, dry or soaked.

Power source

Electric is great for indoor use and has lower emissions. Diesel gives you power and autonomy outdoors. Manual tools still have their place for tight spots and quick jobs. Your choice should reflect both job-site constraints and energy needs.

Mobility and maneuverability

If the equipment can’t turn, pivot, or fit through your tightest pinch point, it’s going to sit idle more than it moves. Compact footprints and smart mobility features can make all the difference between a constant workflow and constant workarounds.

Automation level

Looking to reduce labor or boost precision? Automated systems can speed things up and reduce errors; however, they require setup, calibration, and training. The question is: Does automation help you scale, or does it overcomplicate things?

Safety features

Every load comes with risk. Whether it’s a heavy crate on a stairwell or a delicate machine part being moved across a site, the right safety systems, like load-stabilizing features, automatic braking, or remote control, can prevent injuries and save costs.

Durability and maintenance needs

Tough material handling equipment boosts efficiency. And it saves you from downtime. Look for rugged builds, corrosion resistance, and designs that are easy to service. Bonus points for machines that don’t require a specialized technician every time something goes wrong.

Modular attachments and customization

No two jobs are the same. Equipment that adapts to your changing needs, whether through custom platforms, lift arms, or track configurations, will stretch your investment a lot further than single-purpose machines.

Total cost of ownership

Sticker price is just the start. Factor in energy use, maintenance costs, operator training, downtime, and lifespan. Sometimes the “cheaper” option ends up being the most expensive mistake.

Material handling equipment applications

Every job site has its own unique rhythm and set of challenges. That’s why material handling equipment isn’t only for warehouses or industrial plants. It shows up wherever things need to be lifted, shifted, loaded, or cleared. From construction zones to e-commerce fulfillment centers, the right equipment keeps operations running safely and efficiently.

Here’s where material handling solutions make the biggest impact:

- Construction/demolition: Transporting concrete, rebars, and tools

- Mining: Cleanup after blasting, moving ore or waste, and tight-access zones

- Warehousing: Inventory organization, order picking, and pallet movement

- Manufacturing: Assembly line feeding, waste removal

- Logistics: Loading/unloading trucks and containers

- Retail and E-commerce: Shelf stocking and parcel handling

- Utility-Electrical: Safe handling of batteries, switchgear, cabinets, and transformers in stairwells or tight back-lot spaces

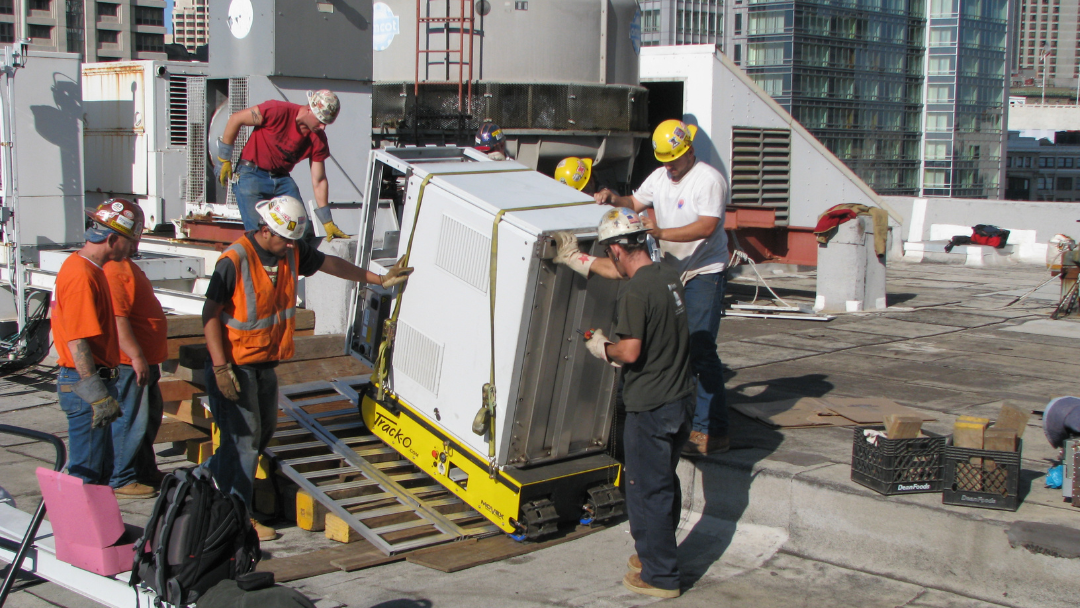

- Building Services (HVAC, Plumbing, Electrical): Safe handling of HVAC roof units, boilers, and furnaces in stairwells or confined spaces

Find More Movex Applications for Everyday Handling

Material handling equipment: Your competitive edge

When every moment and every move costs time and money, having the right material handling equipment can drastically improve employees’ work.

Jake learned that the hard way. After months of muscle strain, delays, and near-misses, he finally brought in a stair climber and tracked carrier from Movex Innovation to tackle one of the tightest projects he’d seen all year. What used to take four guys half a day now takes one operator under an hour—with zero damage, zero stress, and zero risk.

That’s the thing. When you’re investing in material handling equipment, you ensure safety and peace of mind. So here’s your final tip: match the right equipment not to a spec sheet, but to the real rhythm of your work: your spills, tight corners, heavy lifts, and early-morning rushes. Because when your material handling solutions keep pace with your operations, every shift stays profitable.

READ OUR LATEST ARTICLES