Heavy-duty equipment: Boosting construction material handling efficiency

Written by William Nicholls | August 12th 2025

Some material handling equipment on construction sites can be frustrating. Others really put your efficiency to the test.

Narrow corridors. Steep stairs. Basement mechanical rooms with barely enough space to turn around. You don’t have the luxury of time or of trying to wedge in construction material handling equipment that just doesn’t fit.

That’s where Movex Innovation comes in.

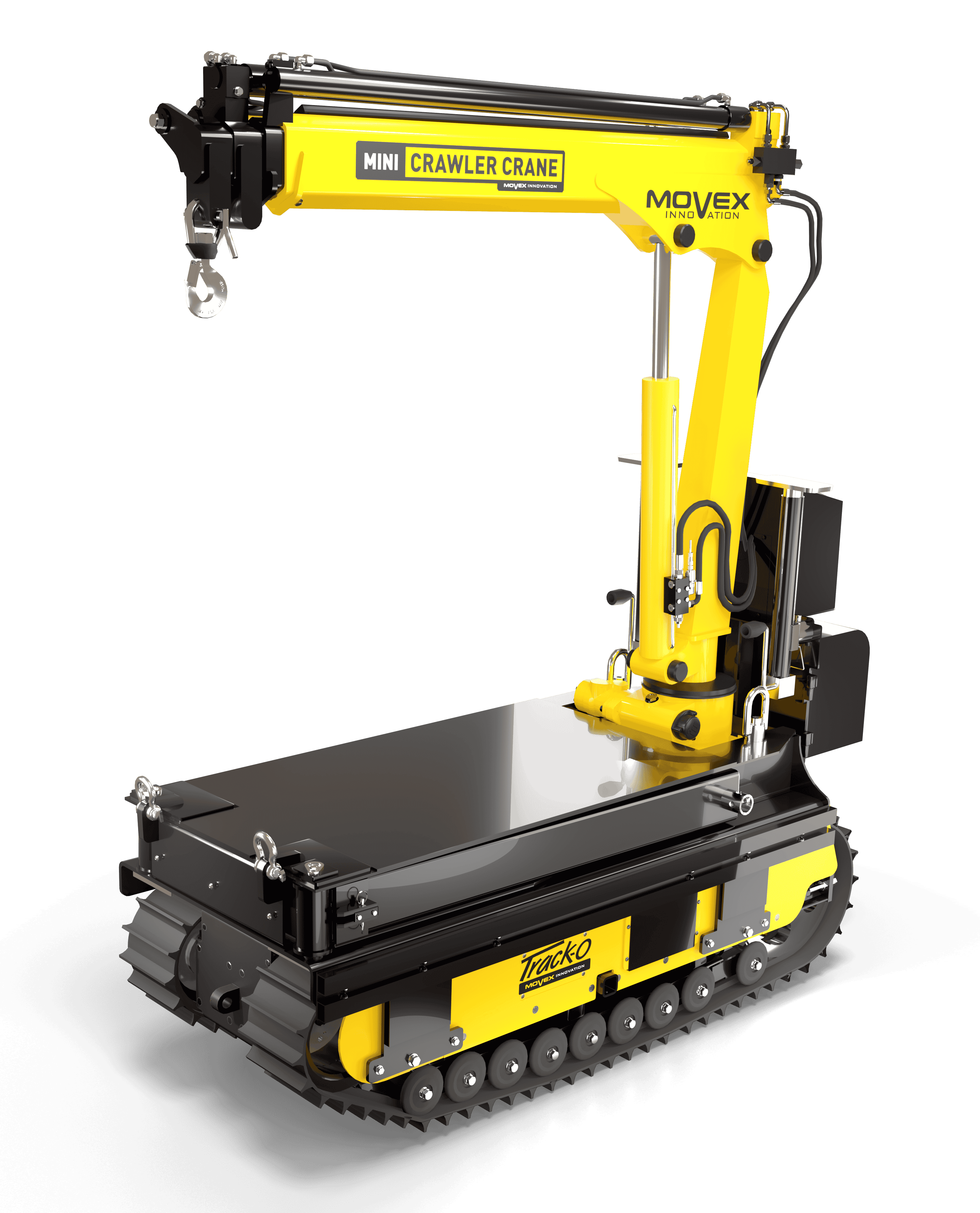

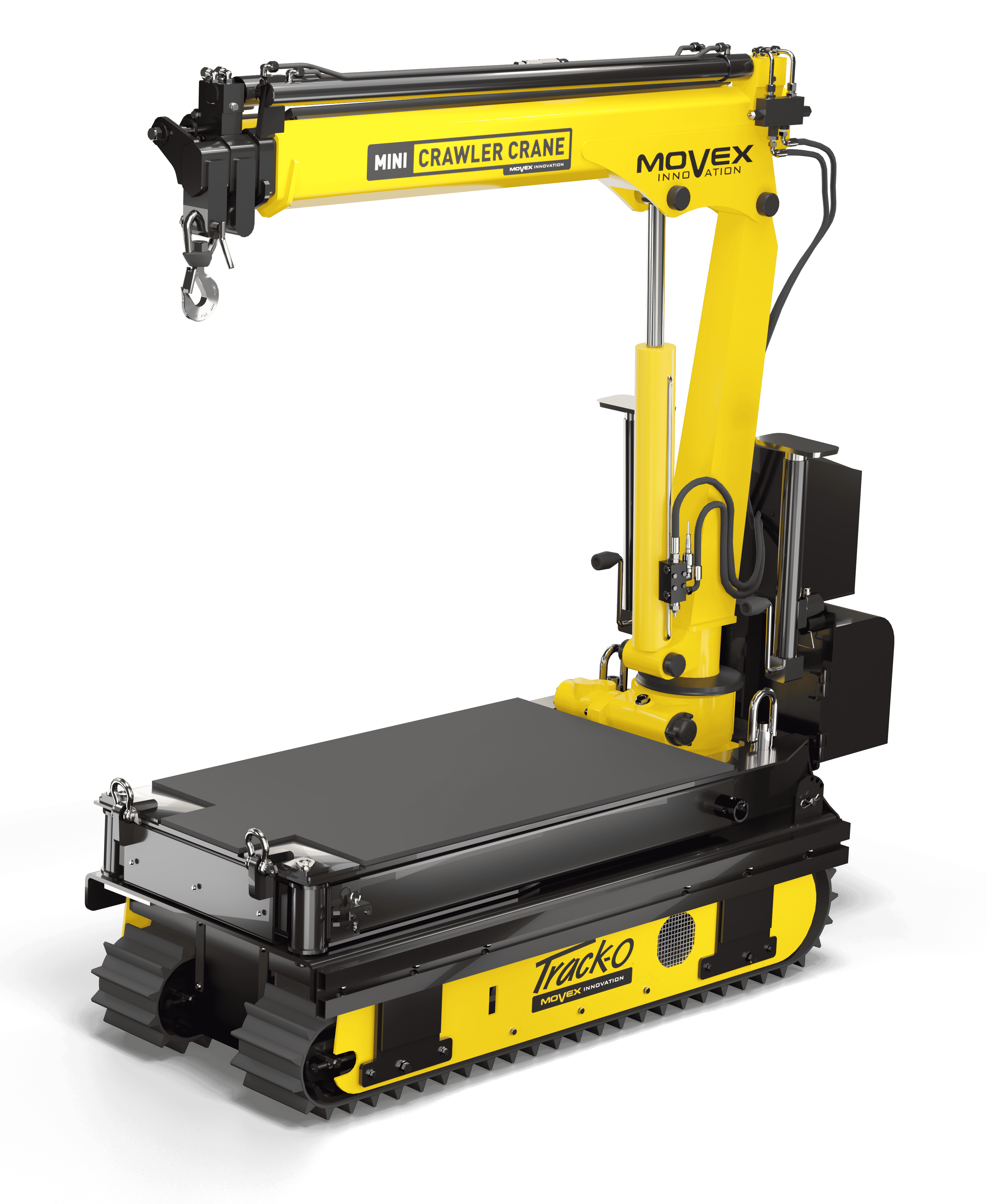

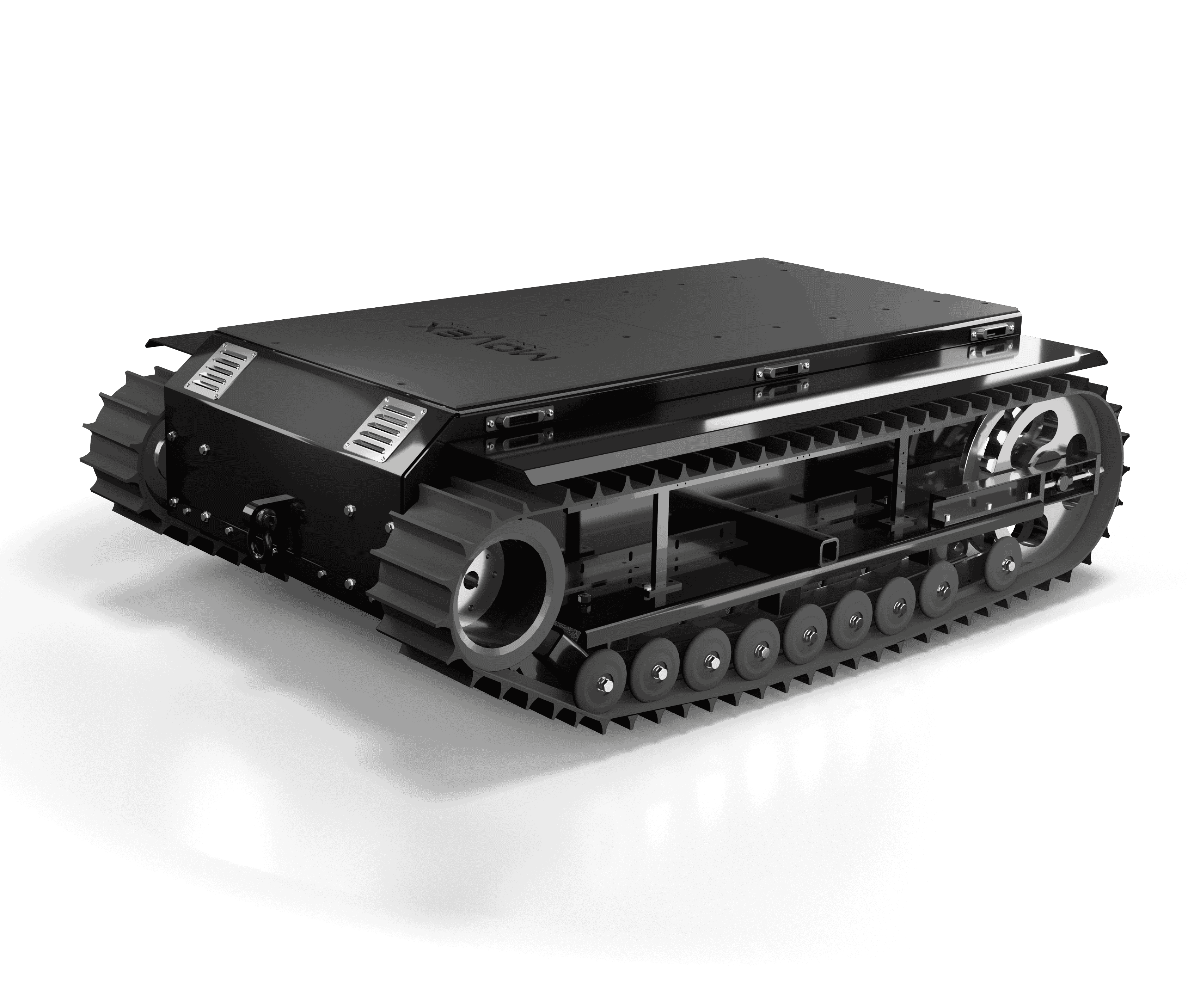

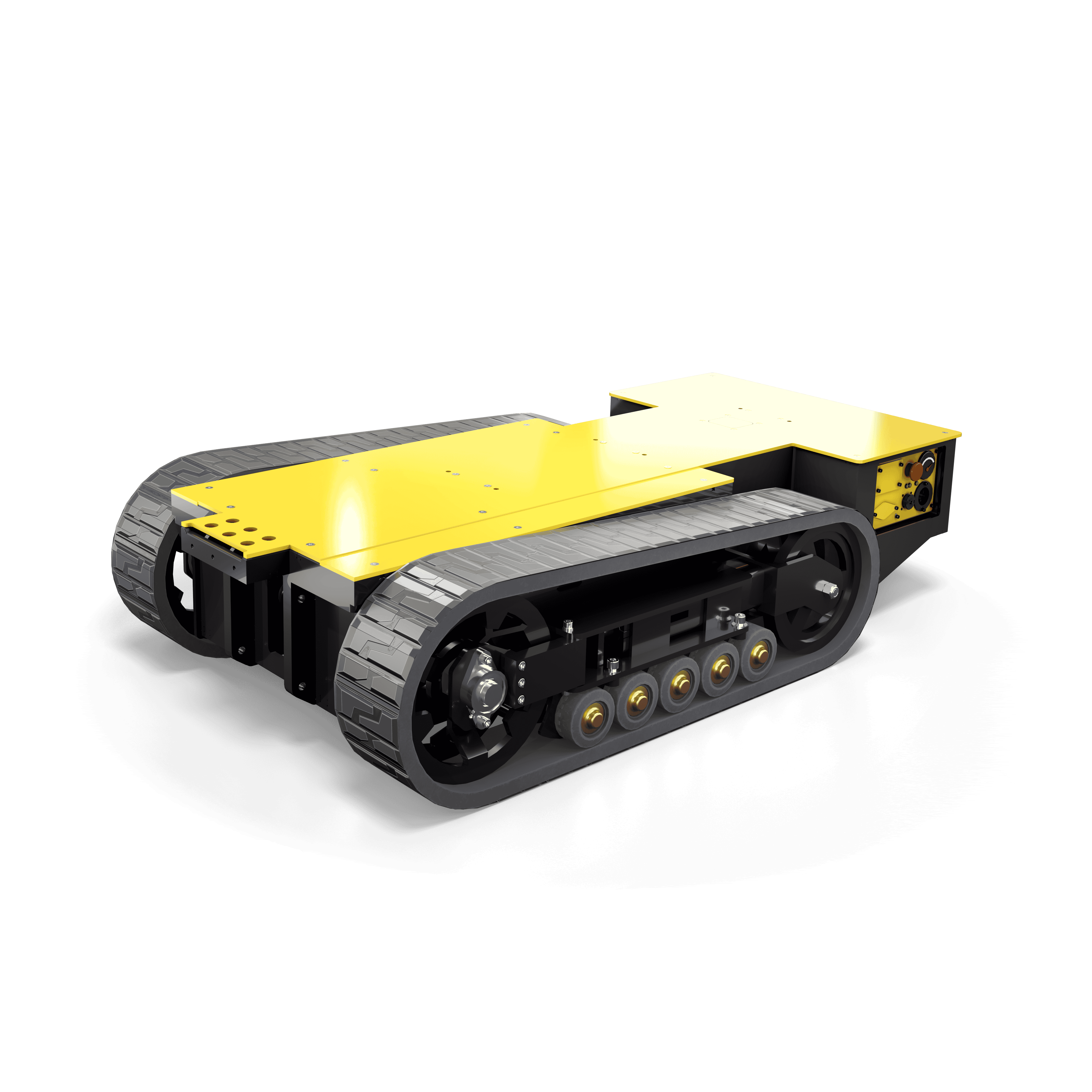

When conventional material handling equipment can be hard to use for construction jobs, Movex keeps your workers moving. Our ultra-compact, electric-powered material handling equipment is designed specifically for the real-world challenges of material handling in construction, especially in tight, awkward, or hard-to-reach places.

Here are the benefits of Move Innovation’s material handling equipment in construction and demolition.

Easier access to confined and hard-to-reach areas

Try rolling a pallet jack into a stairwell. Or squeezing a skid steer through a narrow tunnel. You can’t. But with Movex’s stair climbers and carriers, you can move heavy loads in basements, up to high floors, tunnels or between buildings without compromising operator safety or speed.

The equipment’s compact footprint and remote-control operation make it ideal for constrained spaces, hazardous areas, or facilities where user safety can easily be on the line. Think hospitals, schools, or multi-use buildings under renovation, which are places where every material handling move has to be precise.

Increased productivity with fewer workers

In the construction industry, labor shortages and tight deadlines aren’t going away anytime soon. If you’ve got a tight crew and even tighter deadlines, Movex Innovation helps you do more with less.

With the right material handling equipment in construction, a single operator can transport heavy materials—HVAC units, electrical cabinets, tiles, tools—without the need for multiple laborers or dangerous manual lifting.

Jobs that used to take a team can now be completed faster by one person using a remote-controlled stair climber or all-terrain carrier. This means more work done per day, fewer delays, and less physical strain on your team members.

Reduced downtime and maintenance

Combustion engines aren’t built for enclosed construction sites. They require constant maintenance and fill the air with toxic fumes. Movex Innovation’s electric motors eliminate all of that. No oil changes. No risk of overheating. Fewer moving parts. And no need to shut down an indoor job site because your equipment’s choking the air.

By minimizing maintenance and maximizing uptime, these pieces of construction material handling equipment allow you to keep your schedule on track and accelerate throughput.

Discover our line-up of material handling equipment

Lower operating costs

Fuel costs and material handling equipment maintenance bills erode your margins fast. Movex Innovation helps cut those expenses right at the source. With electric-powered construction material handling equipment, you reduce or slash fuel needs entirely. And with fewer breakdowns and parts to replace, your overall cost of ownership drops significantly.

If you’re managing multiple job sites or long-term projects, that kind of reliability adds up. It’s not only a smart operational decision. It’s a financial one that can impact the entire budget.

Improved safety

Construction sites already carry enough dangers. Add stairs, cramped areas, and heavy materials to the mix, and it’s easy for a single misstep to turn into a workers’ comp claim or a job site shutdown.

Movex equipment helps you stay ahead of occupational health and safety regulations by replacing high-risk manual human tasks with safer, mechanical solutions, such as construction material handling equipment. Remote controls mean workers aren’t overexerting, overreaching, or putting themselves in awkward, injury-prone positions. The stair climbing and carrier machines take the weight, while keeping workers at a safe distance.

The result? Fewer incidents, fewer lost-time injuries, and better compliance with safety protocols. Over time, that adds up to lower insurance premiums, fewer claims, and a reputation for being the kind of contractor teams actually want to work for.

Sustainability and compliance

Compliance requirements on emissions, noise, and job site safety are getting stricter—and for good reason. Movex makes compliance easier by offering equipment that’s quiet, clean, and electric.

This matters on projects where environmental standards are non-negotiable. It also makes life easier on any job site, especially those running multiple shifts or operating in densely populated areas.

Versatility across trades

Movex gear isn’t specialized for just one task. It’s built to adapt, regardless if you are:

- Installing cumbersome HVAC systems or water tanks

- Transporting tile and drywall to high-rise floors

- Moving electrical panels or water heaters through narrow staircases

- Clearing out post-demo debris from a multi-level structure

This flexibility makes it a solid investment for general contractors, tradespeople, and general workers alike.

Built for the realities of construction material handling

Every construction site has its own challenges, but most share one thing in common: conditions that rarely match what’s on paper.

Movex Innovation’s material handling equipment is built for exactly that kind of unpredictability, where teams are working around the clock and safety can’t be sacrificed.

We have put together a list of our top construction material handling equipment and their applications

Material handling in confined spaces

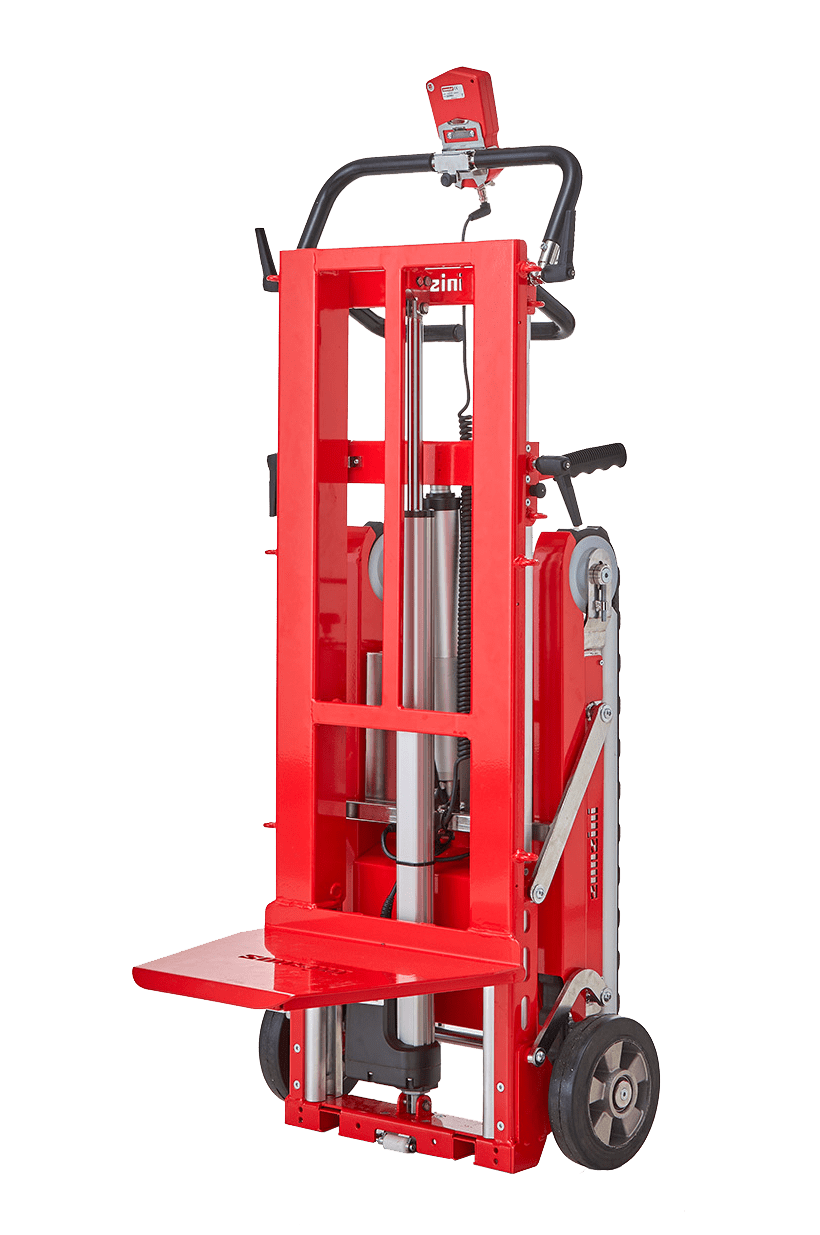

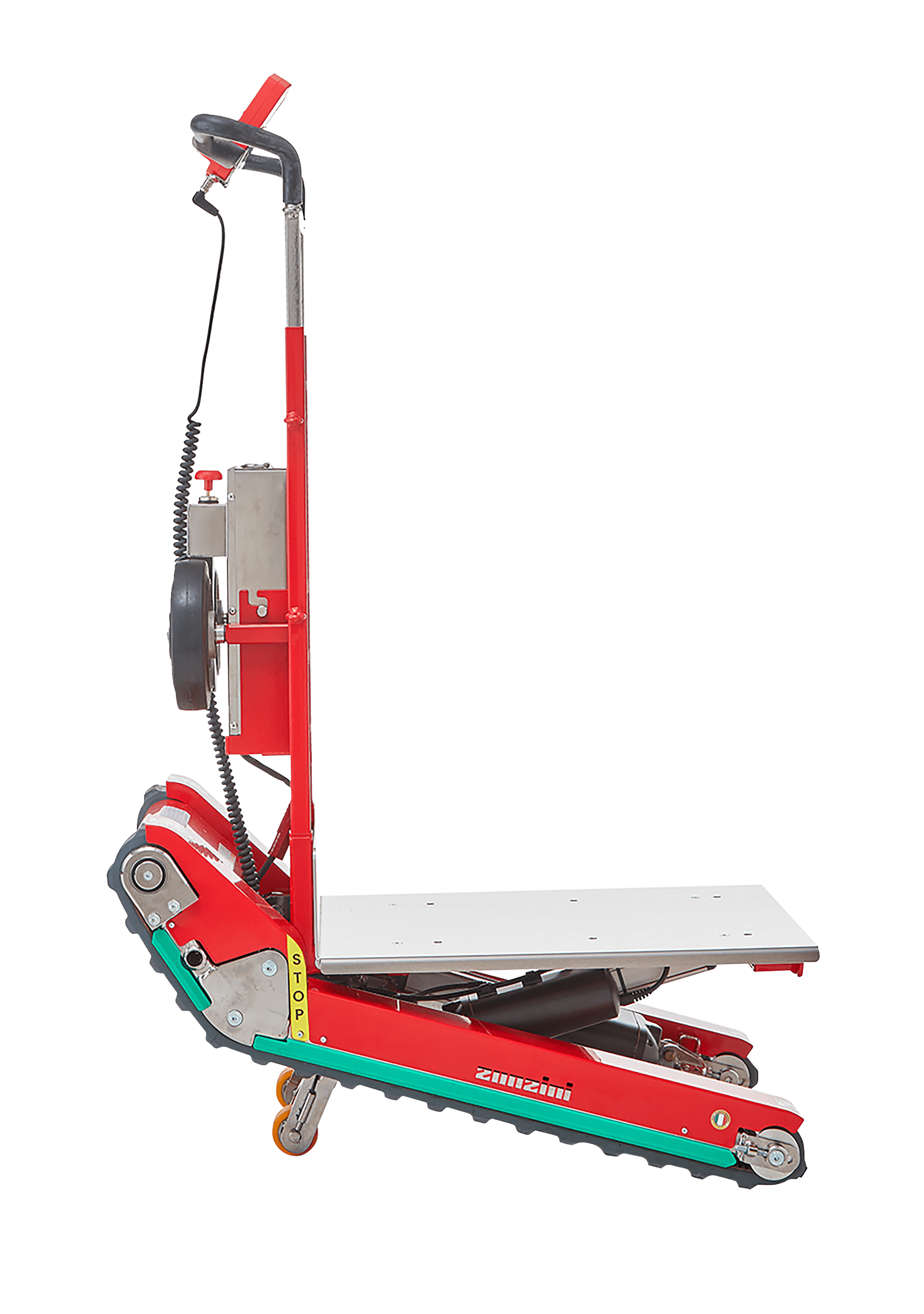

Movex stair climbers and carriers (like the TT-47, TT-66, Mini-Dumper, and Zonzini stair climbers work well in mechanical rooms, basements, rooftops, and tight access zones. They move everything from tools and raw materials to large equipment, all without the bulk or limitations of traditional machinery.

Stair climbing for heavy loads

Getting large items up or down stairs doesn’t have to involve brute strength and straps, or legacy stair climbing dollies. Movex Innovation’s material handling equipment takes on the tough climbs, transporting all types of construction equipment, building materials, and more. One operator, one stair climber, and the job gets done safely.

Our stair climbing material handling equipment includes: TT-47, TT-66, and Zonzini stair climbers

Debris removal and site cleanup

During renovation or after demolition, clearing out chunks of concrete, drywall, and insulation is no small feat, especially in enclosed spaces. The Mini-Dumper is a go-to piece of construction material handling equipment for cleanup in places traditional loaders can’t reach, keeping your site clean without any unnecessary delays.

Indoor construction and renovation

In hospitals, schools, and office buildings, noisy and polluting machines aren’t an option. Movex Innovation’s material handling equipment operates quietly and cleanly, making it the ideal choice for occupied buildings where disruption needs to be kept to a minimum. Check out our TT-47, TT-66, Mini-Dumper, and Zonzini stair climbers

Elevator or shaft transport

When elevators are down or under construction, tools and materials still need to be moved around. Our electric hand trucks are a practical alternative; they are capable of navigating elevator shafts, underground garages, or tight vertical spaces where cranes or lifts aren’t practical.

High-rise and multi-story projects

When elevators are out of service or simply not an option yet, materials still need to be transported. Hauling drywall, tile, or flooring up stairwells isn’t just tiring; it chips away valuable time and crew capacity. Movex Innovation’s stair climbers and urban carriers are ideal for situations where cranes and lifts are impractical, such as handling mid-sized loads. Your employees can keep working floor by floor without having to wait on larger logistics or bring in oversized machinery just to move a few pallets.

Other field applications

Beyond core construction tasks, Movex Innovation’s material handling equipment in construction is proving valuable for:

- Transporting drilling materials in restricted areas

- Selective demolition and concrete chipping projects

- Municipal infrastructure upgrades in tight downtown zones

Equipment rental options that work the way you do

Not every job calls for a permanent investment. That’s where rental options can be an excellent way to benefit from a new generation of electric material handling equipment.

For occasional or short-term needs, Movex Innovation offers direct equipment rental across North America. You can also rent through your preferred rental center thanks to our sub-rental program, or check with local rental partners already carrying Movex Innovation’s solutions. Whether you’re testing the gear on a specific job or managing fluctuating demand, we make it easy to get the right equipment, when and where you need it.

Get a quote today

RESOURCES