Mining iron ore processing flow: The invisible work that keeps the plant running

Written by William Nicholls | February 2nd 2026

From the outside, an iron ore processing plant looks like a model of industrial control. Conveyors run endlessly. Crushers chew through rock with mechanical indifference. Screens vibrate, mills turn, and pellets move steadily toward rail or ship.

Everything critical is automated. Everything measurable is optimized.

And yet, every maintenance manager knows the truth: the real work happens in the margins. Under the conveyors. Around the crushers. Between levels. In the places that no one designed to be ergonomic, accessible, and, least of all, clean.

That’s where minor challenges and inefficiencies gradually add up—and impact an operation’s margins.

A shift doesn’t start at the crusher. It starts with what’s left behind.

At the open-pit mine, run-of-mine material hits the system fast. Hoppers fill. Chutes discharge. Conveyors take over. And almost immediately, spillage begins.

Not catastrophic failures. Just gravity doing its job.

Material drops where it shouldn’t. It builds up around hopper skirts. It accumulates under conveyors. Operators step over it. Maintenance crews note it and move on. There’s always something more urgent.

Until there isn’t.

Cleaning these zones manually means putting people close to moving equipment, mobile machinery, and unstable ground. Standard skid steers don’t fit. Shovels and wheelbarrows don’t scale. So the mess grows, shift after shift.

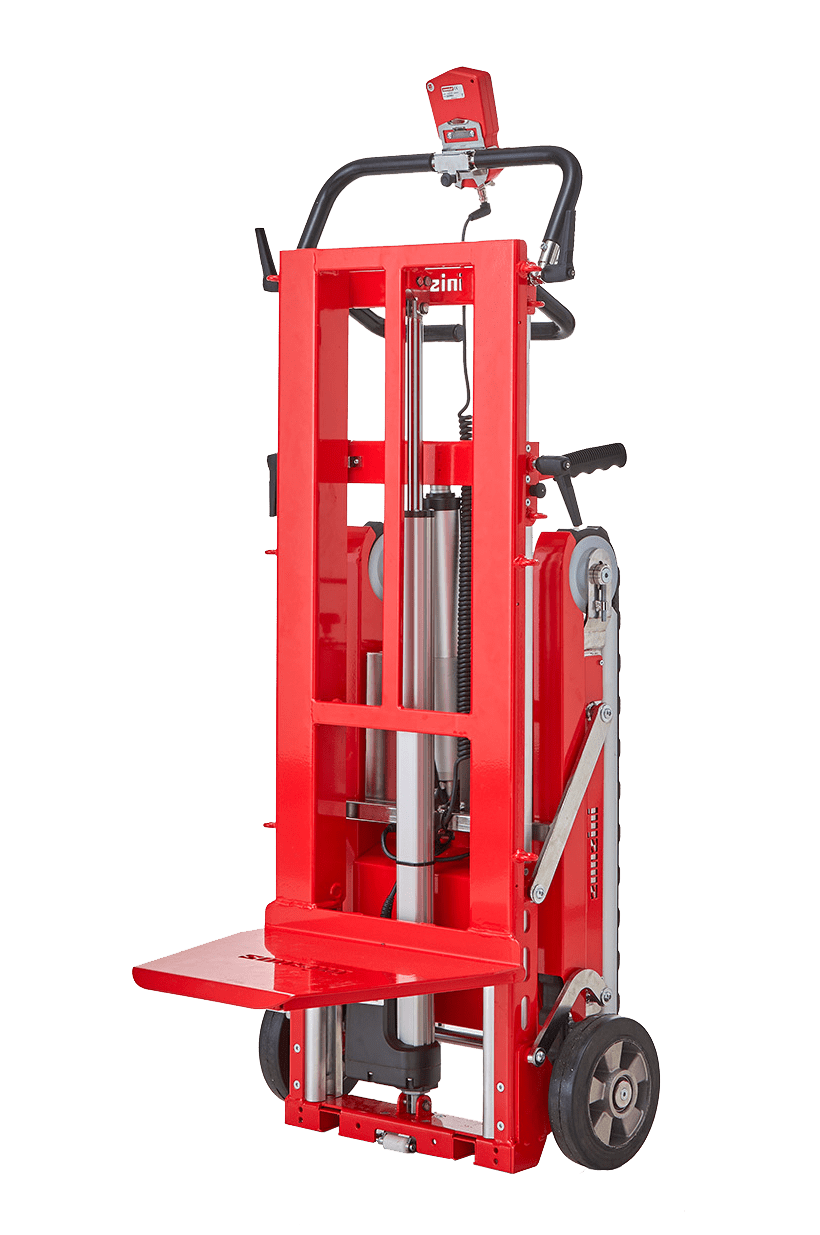

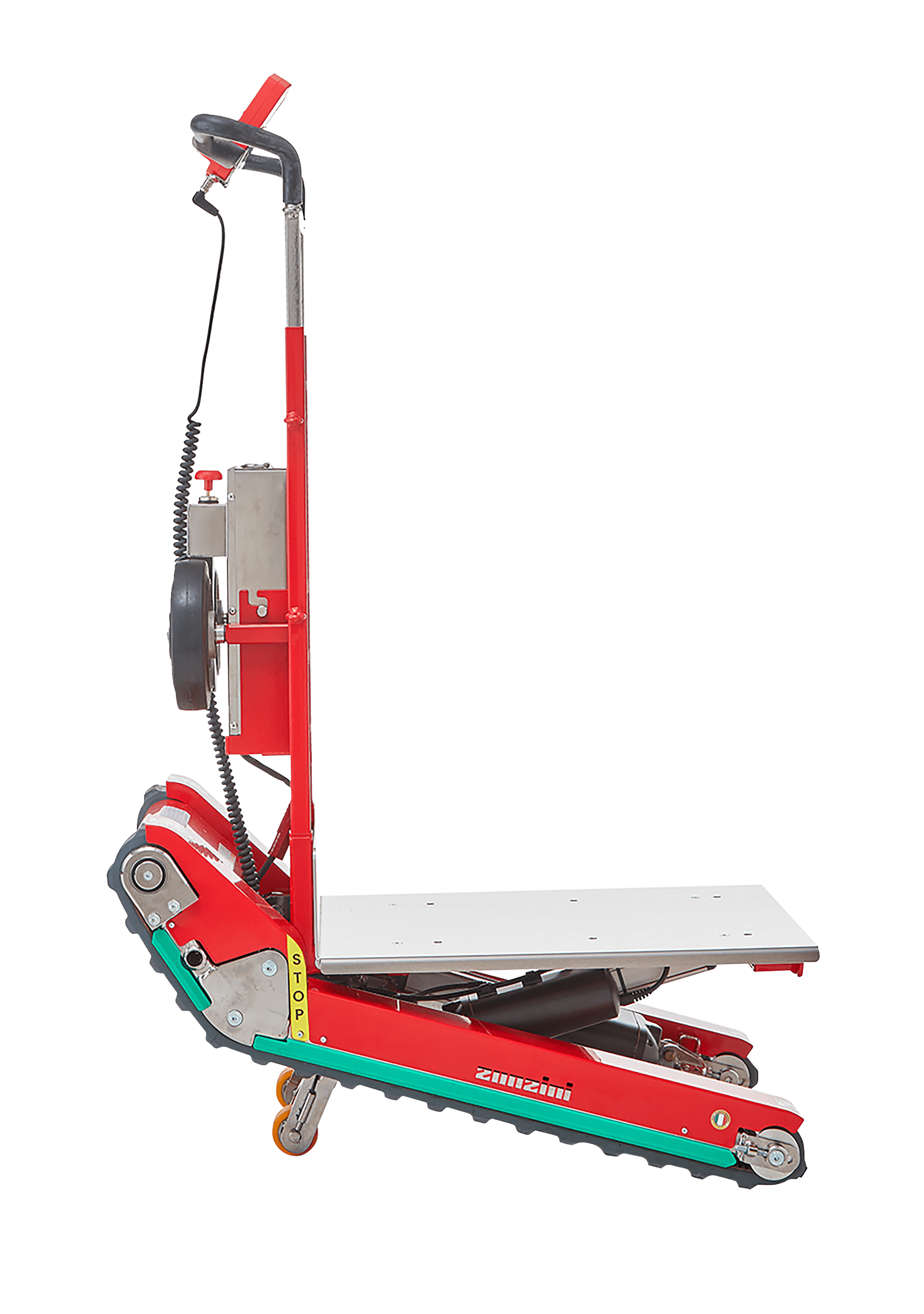

This is where ultra-compact, remote-controlled equipment like Movex Innovation’s MINIDOZER, a robust electric mini loader, comes in. Not by replacing other heavy machinery, but by doing the work everyone knows needs to be done, without putting someone in harm’s way.

Primary crushing

Primary crushers get attention. They have to. Jaw crushers, gyratory crushers, cone crushers—when they stop, everything stops.

But the areas around them? Those are a different story.

Material builds up around crusher bases. Spillage collects at discharge points. Dust settles everywhere. Room to work gets worse over time. What started as a cleanup issue becomes a safety problem, then a maintenance delay.

In many plants, cleaning around primary crushers is deferred until shutdowns. Not because it’s unimportant, but because reaching those zones safely during operation is difficult.

Ultra-compact, low-profile mini-loaders change that equation. Instead of waiting for a shutdown window, cleanup can happen while the crusher keeps running. Production stays in check. The risk is minimized.

Secondary and tertiary crushing

By the time material reaches secondary and tertiary crushing, vibrating screens and transfer points operate continuously, generating constant fines and spillage.

These are not friendly environments for people. Noise, dust, and motion combine to make manual cleanup slow and hazardous. And because space is tight, conventional equipment simply can’t get in.

Remote-controlled MINIDOZERS allow operators to stand back, maintain visibility, and clean efficiently under vibrating equipment and transfer points. It’s not glamorous work. It’s necessary work. And doing it regularly prevents small issues from migrating downstream.

Screening

Screening areas are familiar to anyone who’s spent time in a processing plant. Material under vibrating screens. Spillage at conveyor transitions. Narrow walkways that get narrower every week.

Because these areas are hard to get to, they’re often cleaned “when there’s time.” Which usually means during shutdowns, or not at all.

Low-profile MINIDOZERS that fit under conveyors and screens let maintenance teams stay ahead of the mess rather than react to it. Clean floors improve accessibility. Better clearance improves safety. And safety, in the long run, protects uptime.

Grinding and milling

Around SAG and ball mills, cleanup isn’t just about dust. It’s about slurry. Wet material. Slippery floors. Confined spaces.

Manual cleanup in these areas exposes crews to some of the most dangerous conditions in the plant. Yet the work still has to be done.

Compact, remote-controlled mini-loaders allow slurry and spillage to be removed regularly, without putting people directly in the line of fire. It’s not about replacing procedures. It’s about giving crews a safer way to execute them.

Concentration plants

Magnetic separation and concentration plants generate wet spillage as part of normal operations. Over time, that spillage hardens, spreads, and creates serious space problems.

Left unchecked, it interferes with equipment, blocks walkways, and increases slip hazards. Cleanups get harder the longer they’re delayed.

Regular, localized cleanup keeps concentration areas manageable. It reduces risk, improves visibility, and makes maintenance interventions faster when they do occur.

Thickening, filtration, and pelletizing

Around thickeners and filter presses, cleanliness directly affects efficiency. In pelletizing areas, material falls around conveyors, balling drums, and furnace feed chutes.

These zones are often busy, hot, and space-constrained. Cleaning them manually is slow and can eat into production time.

Using compact equipment to maintain these areas keeps operations predictable. Crews spend less time navigating obstacles and more time doing actual maintenance.

Stockyards, rail loading, and final transport

By the time iron ore reaches the stockyard or rail loading area, most of the value has already been created. This is not where anyone wants surprises.

And yet, conveyor spillage continues. Material builds up along structures. Working space degrades.

Ultra-compact machines can work along conveyor lines, between structures, and in tight zones where larger equipment can’t operate. Cleanup happens without interrupting loading schedules or final transport.

The same applies near ship loaders and transfer points. Final handling deserves the same level of attention as the first crush.

In a nutshell, the real bottlenecks aren’t always critical production timelines. It’s everything around it.

How Movex Innovation supports iron ore operations

Most of the processing steps described above are connected by conveyors. The MINIDOZER can also be used to clean beneath conveyors and in areas too tight for standard skid steers to reach.

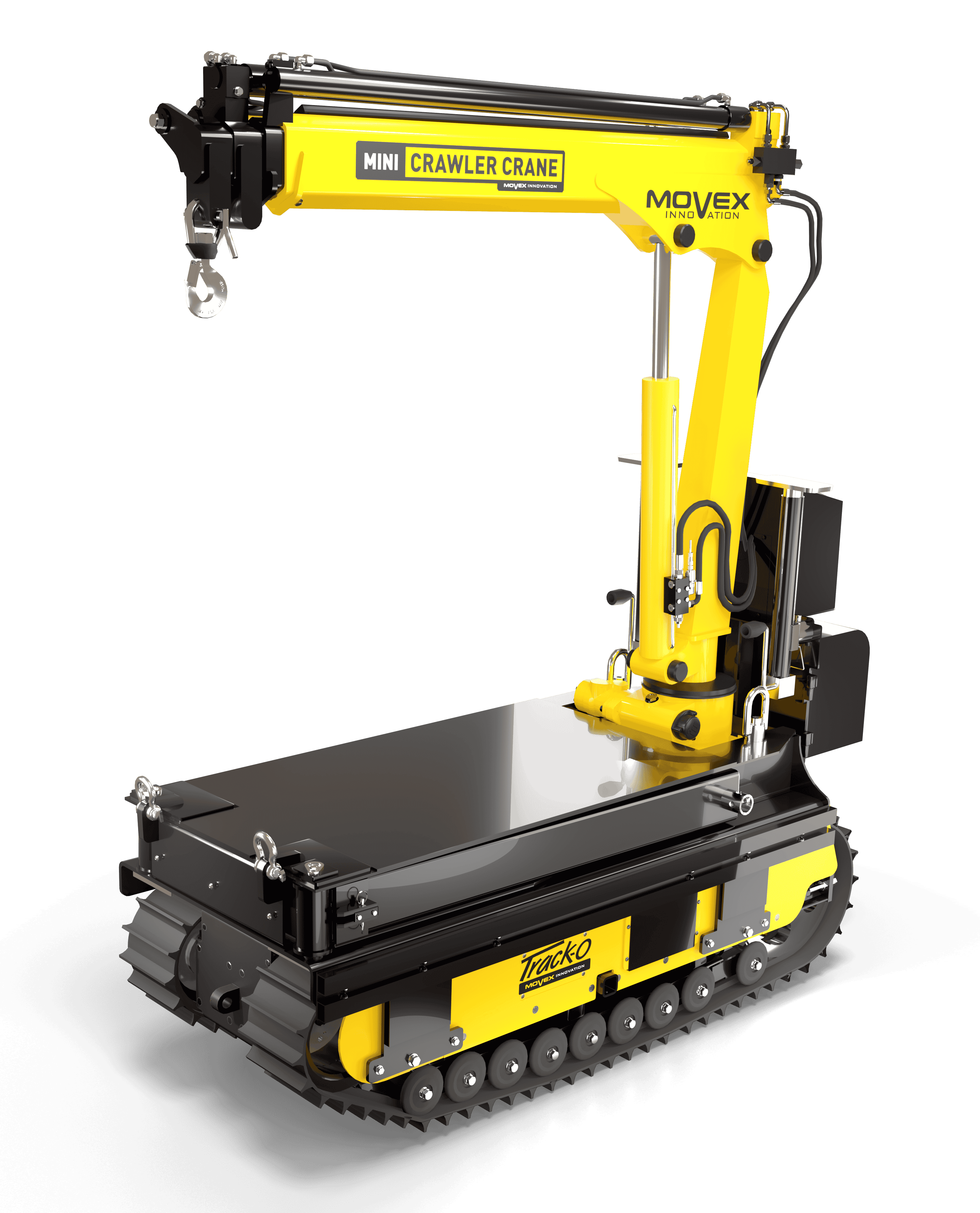

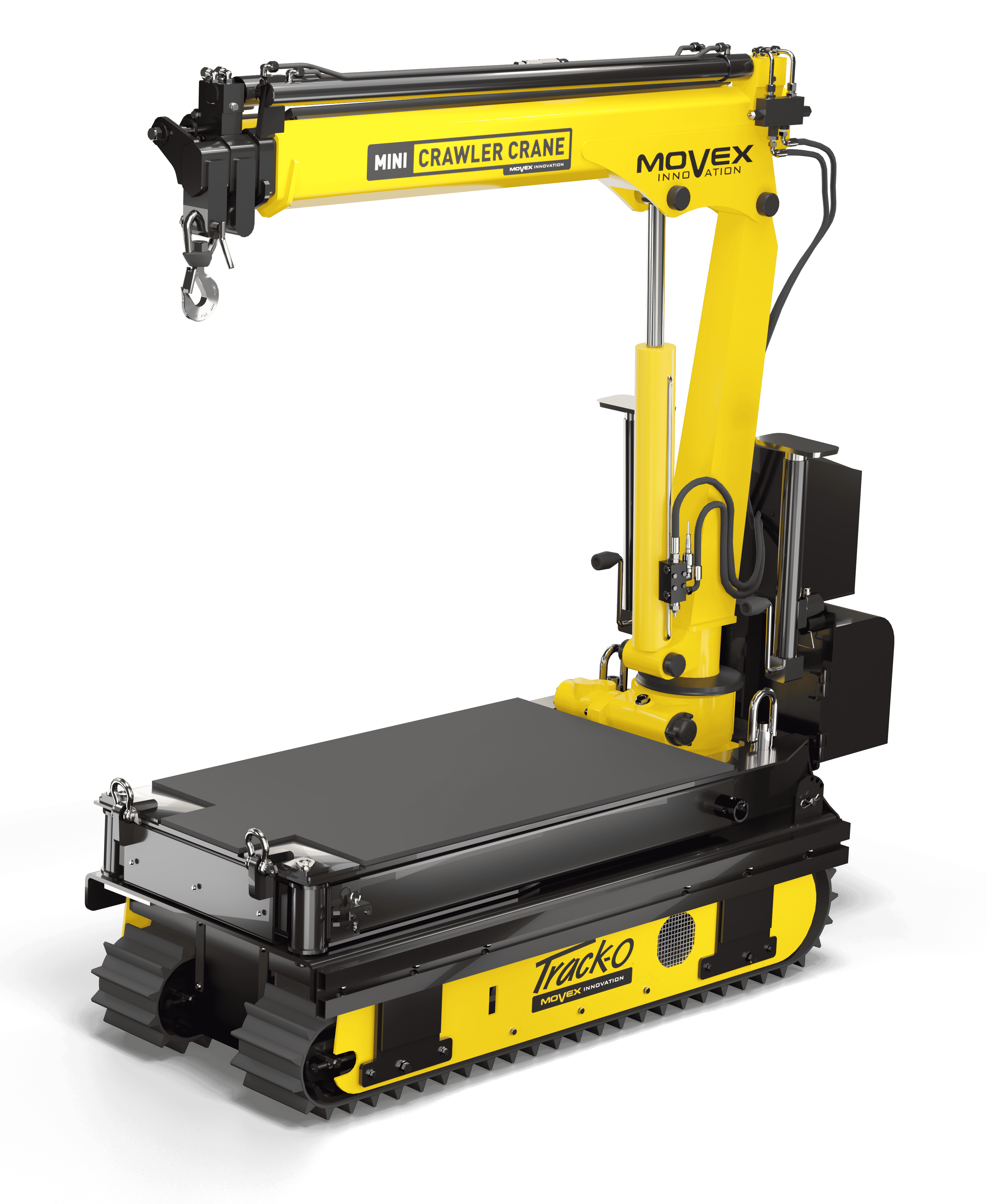

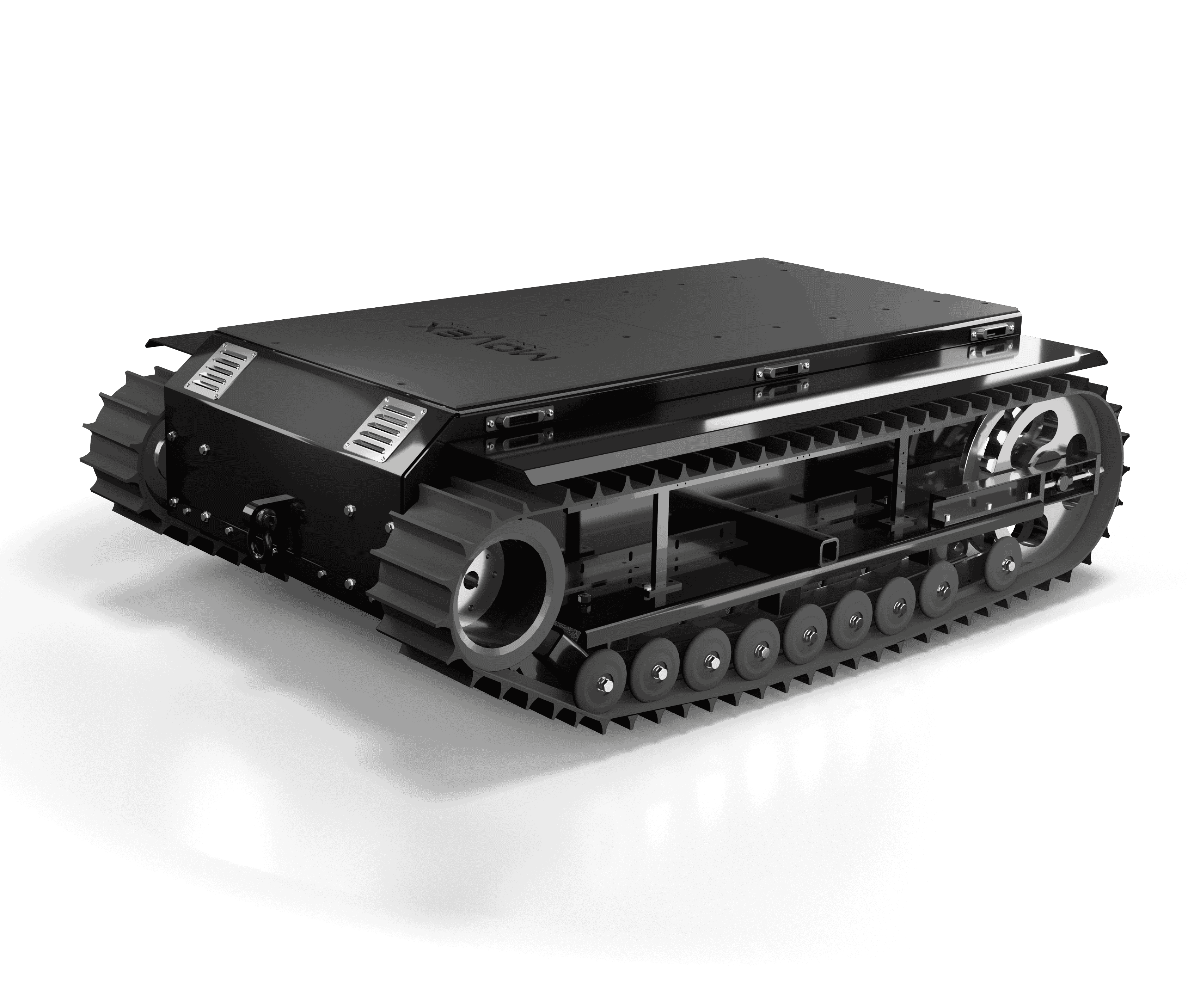

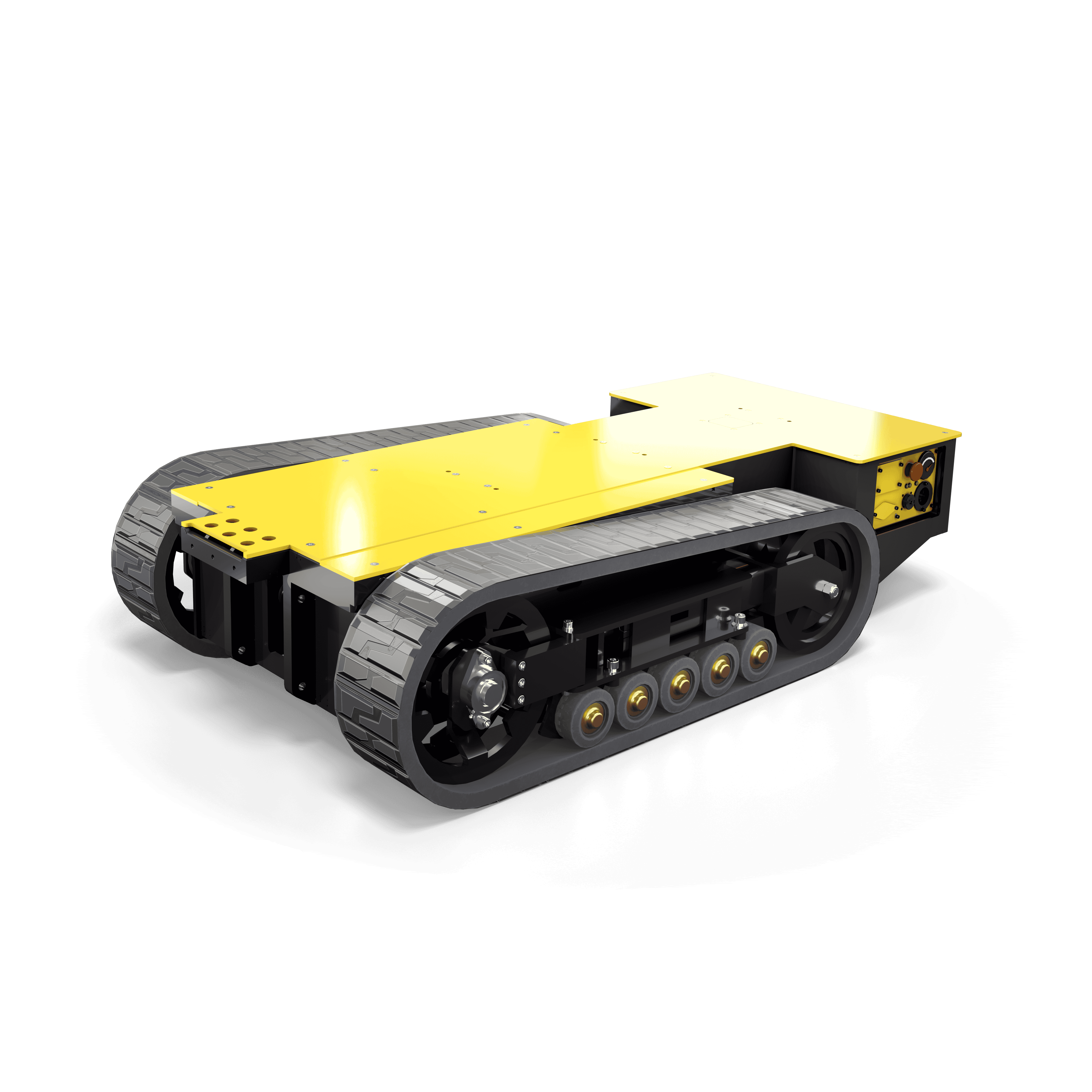

Movex Innovation’s TT-66 stair climbers and mini crawler cranes, like the XC-270, are used to transport tools, motors, gearboxes, conveyor rollers, pumps, control panels, and replacement components to elevated platforms and hard-to-reach areas.

| Department/Steps | What Movex can help you with |

|---|---|

| Open Pit Mine (ROM) | MINIDOZER for cleaning around hoppers, chutes, and under conveyors. |

| Primary Crusher (Jaw Crusher, gyratory crusher, cone crusher) | MINIDOZER for removing material buildup and spillage around crusher bases and discharge areas. |

| Secondary/Tertiary Crushing (Vibrating Plates, screens) | MINIDOZER for efficient cleanup under vibrating equipment and transfer points. |

| Screening | MINIDOZER for cleaning spillage under vibrating screens and transfer points. |

| Grinding/Milling (SAG Mill / Ball Mill) | MINIDOZER cleaning accumulation of slurry, spillage and dust. |

| Concentration (Magnetic separation) | MINIDOZER cleaning wet spillage. |

| Thickening/Filtration | MINIDOZER for maintaining clean work areas around thickeners and filter presses. |

| Pelletizing | MINIDOZER cleaning falls around conveyors, balling drums, and furnace feed chutes. |

| Stockyard / Rail Loading | Conveyor spill cleanup with MINIDOZER. |

| Stockpiles | MINIDOZER for localized cleanup and reclaim assistance in tight or restricted access zones. |

| Boat (Or final transportation) | MINIDOZER for cleanup around ship loaders, transfer points, and final material handling areas. |

The gains most iron ore mines are still leaving on the table

Iron ore mining companies that integrate compact, remote-controlled equipment don’t just improve housekeeping. They unlock real operational benefits:

- Safer working conditions for maintenance crews

- Continuous operation without unnecessary shutdowns

- Higher productivity through faster interventions

- Lower total cost of ownership compared to improvised solutions

- Improved ESG performance through better site cleanliness

- Long service life built for mining realities

None of this requires redesigning the plant. It simply requires acknowledging that optimization doesn’t stop at the conveyor belt. Contact us today and let’s phase in a new era of iron ore processing flows.

Reduce spillage, improve uptime — request a demo today.

READ OUR LATEST ARTICLES