How ultra-compact tracked stair climbers can boost your productivity

Written by leonard | February 7th 2024

An increasing number of companies, including in the general handling, building services (HVAC), and subway sectors, are turning to ultra-compact and electric stair climbers to overcome many common material handling challenges. Tracked stair climbers are pieces of innovative designed to move loads across different terrains, including stairs, to improve material handling efficiency and provide safer working environments for material handling teams.

Ultra-compact stair climbers are enhancing versatility in material handling, surpassing their predecessors with advanced design and features.

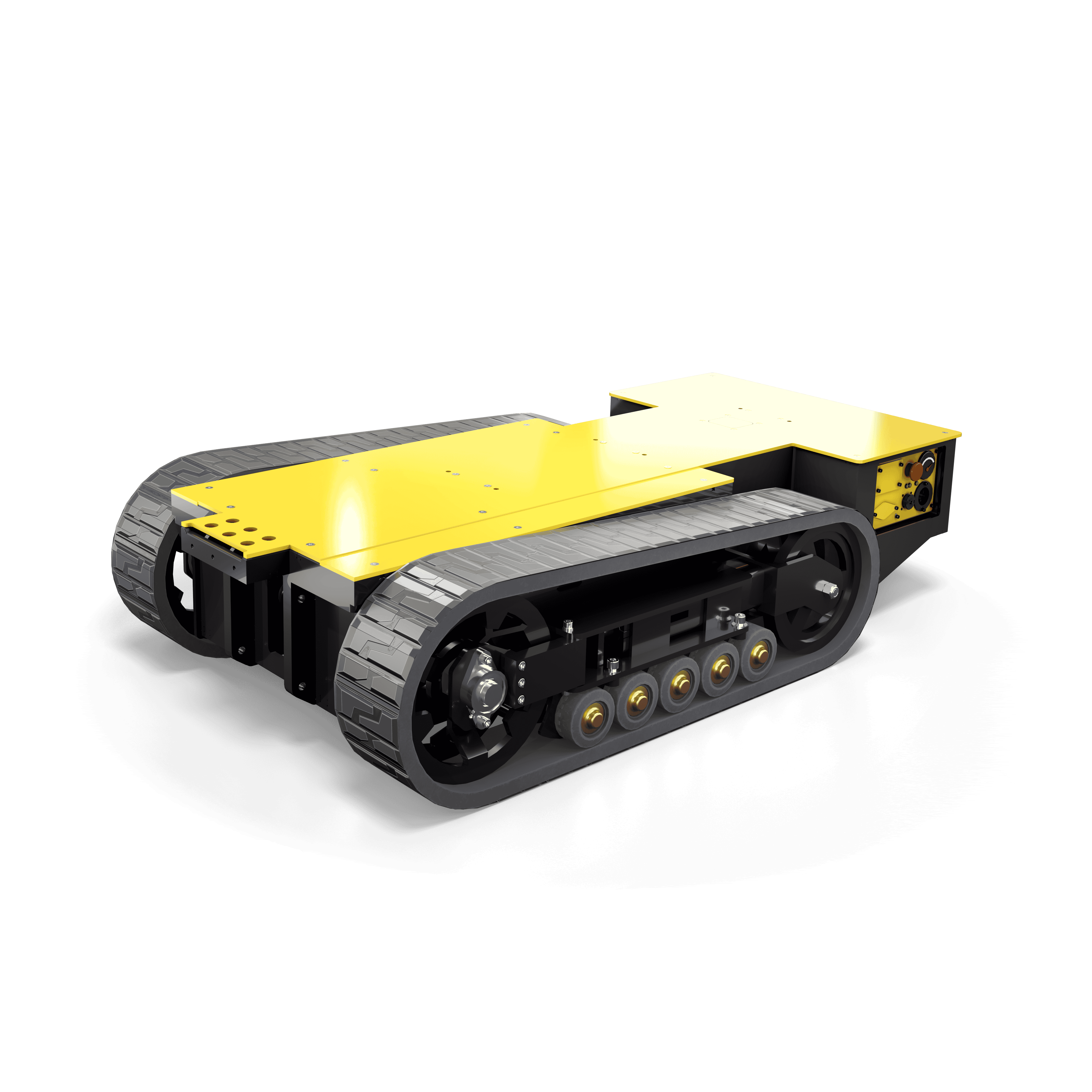

What makes ultra-compact tracked stair climbers different is how their size enables them to carry out complex material handling tasks in confined spaces, flat surfaces, and on all types of stairs. For example, the ultra-compact equipment’s smaller footprint allows them to maneuver through tighter spaces—such as narrow corridors and doorways—where traditional stair climbers could not fit.

Just because they are smaller—often just 30 inches wide—does not mean users must sacrifice performance. More modern ultra-compact stair crawlers are engineered to maintain, if not increase, load capacity relative to their size. The precision control available in ultra-compact models ensures that intricate maneuvers and sensitive procedures, such as transporting valuable, heavy, or cumbersome materials through challenging layouts, can be easily performed. Think: building materials, steel beams, concrete slabs, toolboxes and compressors, to name a few.

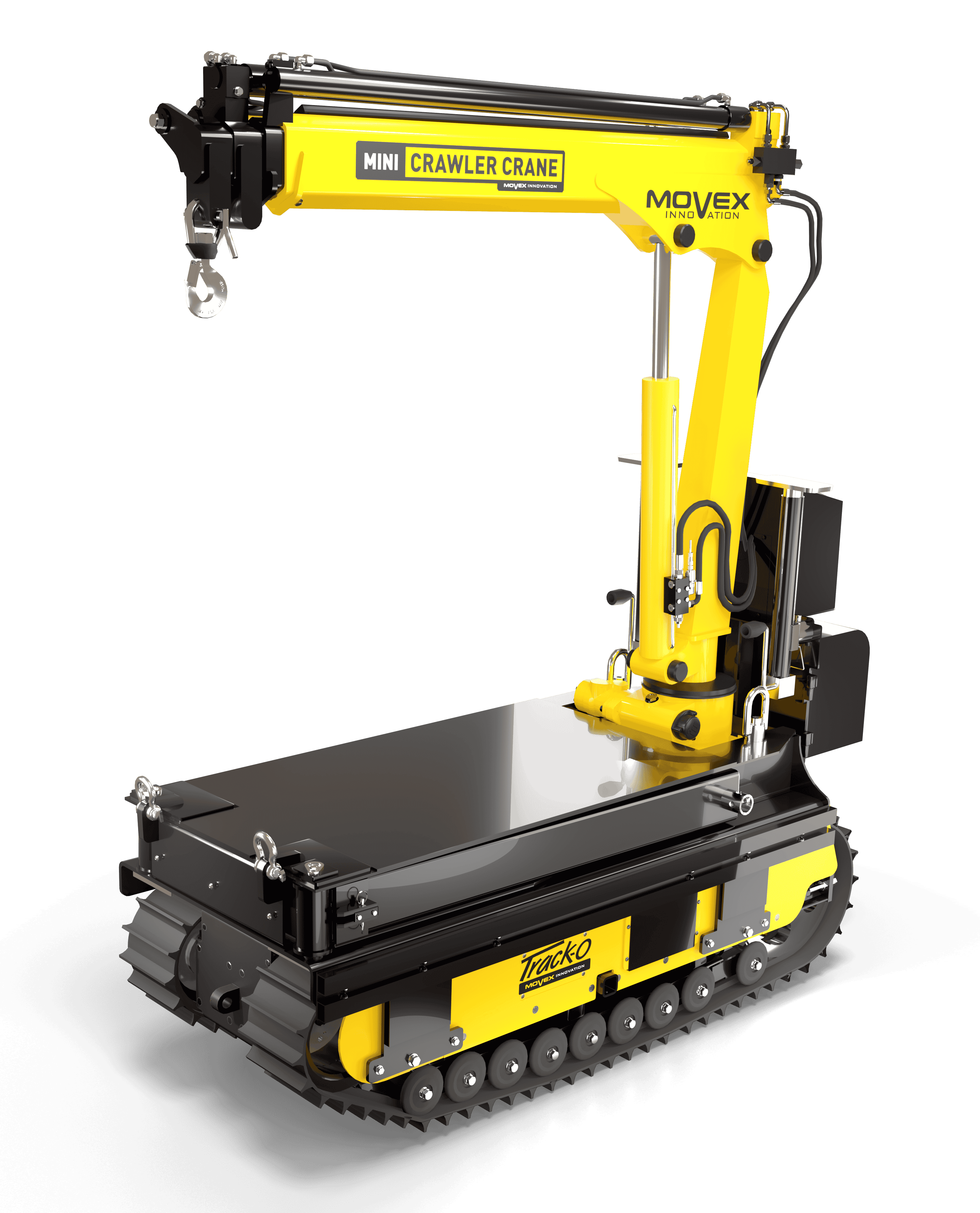

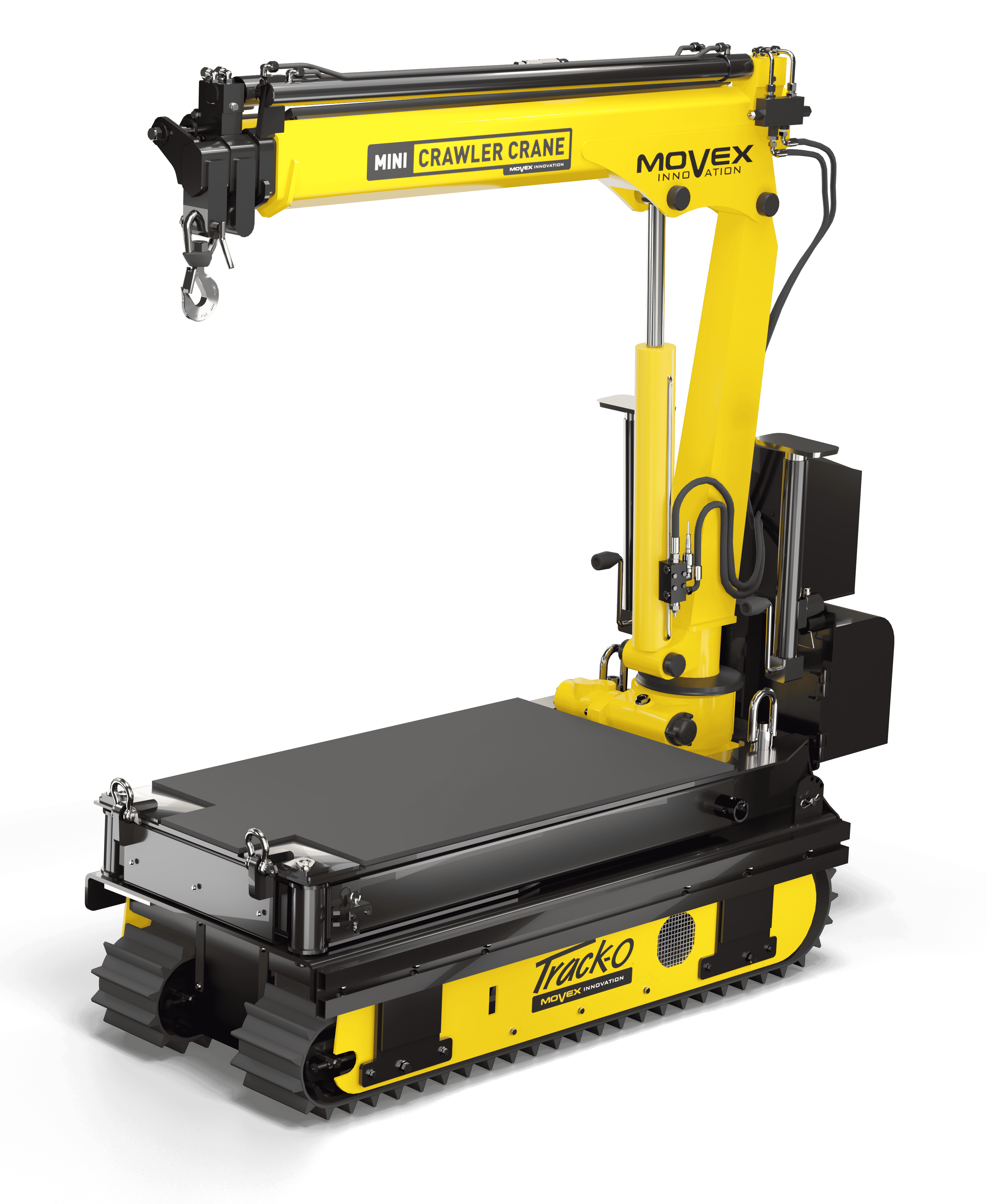

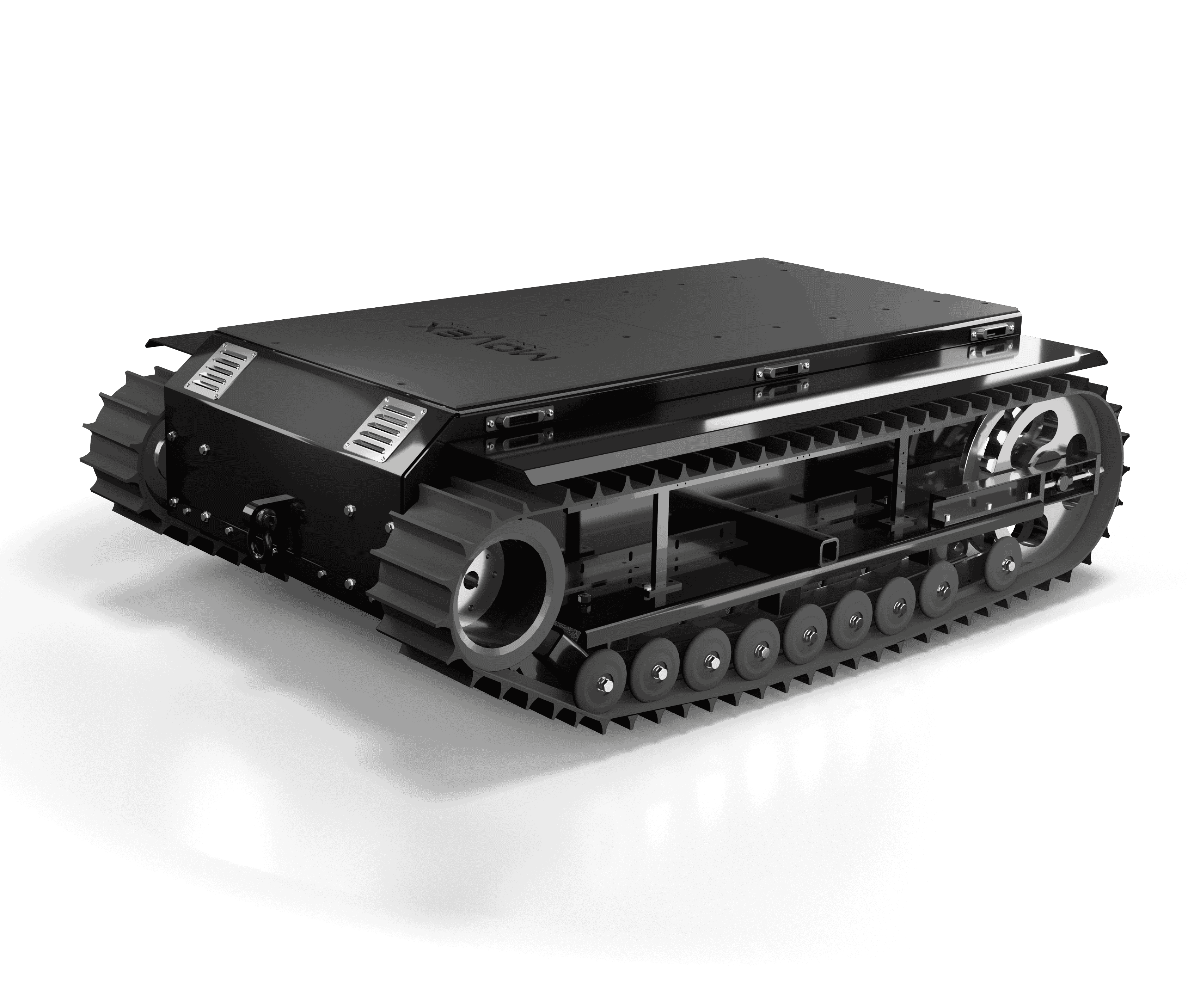

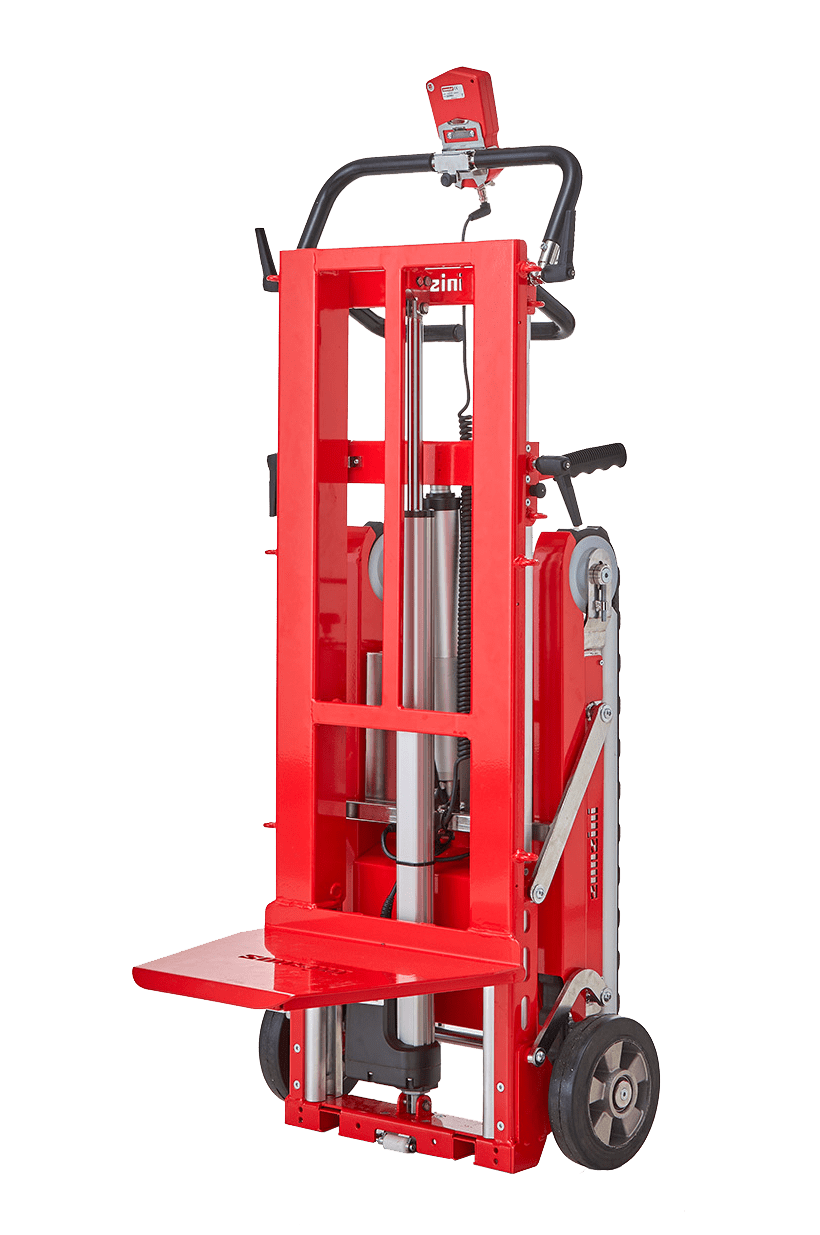

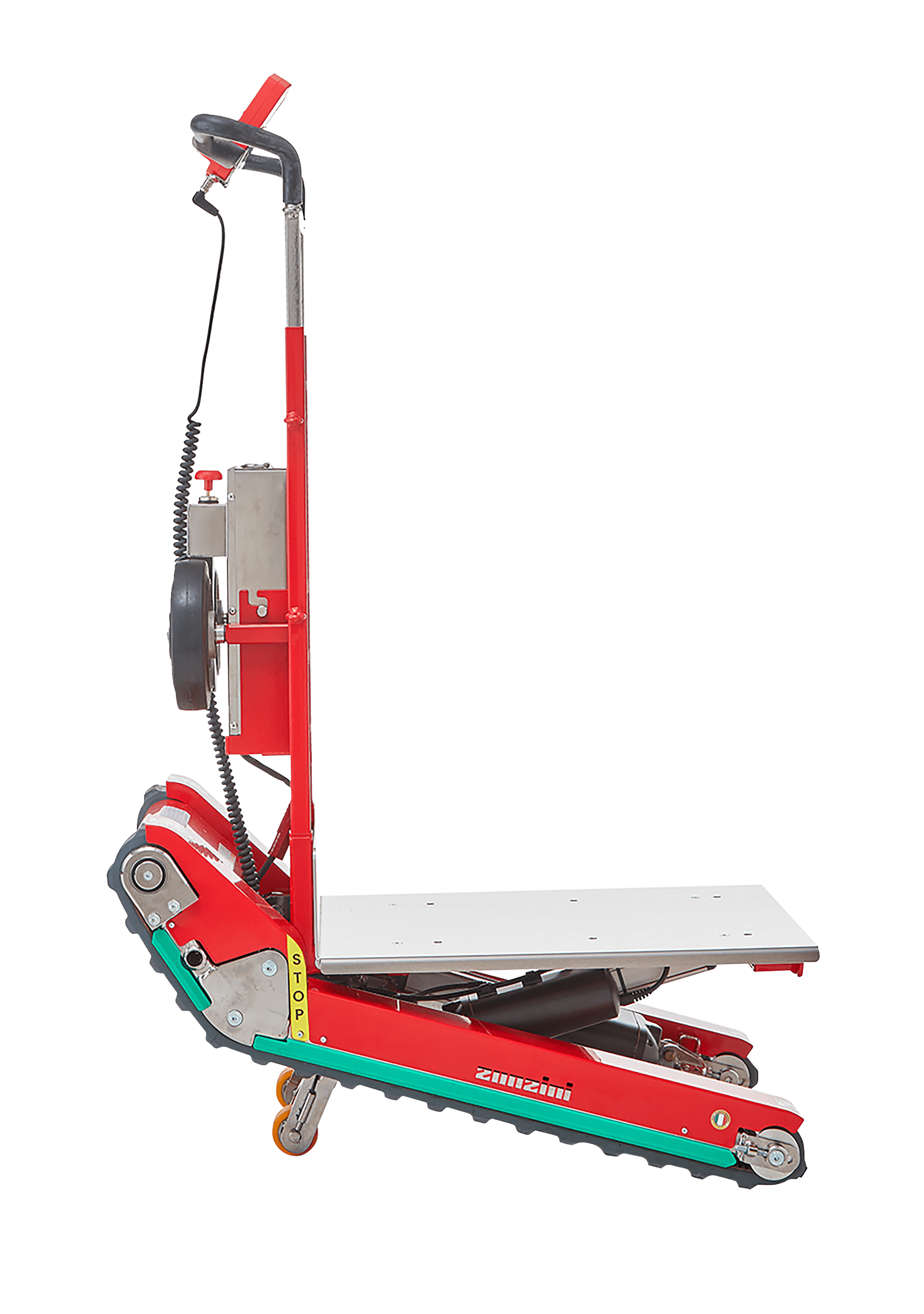

Here are two of Movex Innovation’s five-star reviewed ultra-compact tracked stair crawlers that have helped companies elevate their material handling operations to a whole new level:

Let’s look at the concrete business benefits of ultra-compact tracked stair climbers in more detail.

Worker health and safety

Ultra-compact stair climbers significantly contribute to worker health and safety by mitigating the physical strain and injury risk associated with manually transporting heavy loads over uneven surfaces and up or down staircases. Gone are the days of manual lifting, pushing, and pulling—demanding actions that are commonly linked to musculoskeletal disorders among workers.

Moreover, their compact design ensures easy navigation in tight spaces, minimizing the likelihood of accidents due to operator error or environmental constraints.

Furthermore, because electric stair crawlers are powered by batteries, workers do not inhale any fuel emissions, which could harm their health. No additional ventilation or work health and safety measures are required to reduce the risks associated with exhaust fumes or gas discharge.

Resource optimization

Implementing tracked stair climbers in material handling workflows can reduce labour costs by decreasing the number of operators needed on different job sites. Oftentimes, only one or two workers are needed to carry out material handling tasks with a stair crawler, as opposed to five or six workers with legacy equipment.

Cost reductions

The ultra-compact design of electric stair climbers bypasses the need for demolition or structural alterations in the spaces where the material handling occurs. This also reduces the reliance on using or even renting larger, more expensive equipment, like cranes and service trucks, for moving loads across different levels. What’s more: battery-powered stair climbers allow companies to slash fuel costs, which continue to remain at all-time highs.

Long-term durability

The robust construction of tracked stair climbers and their high-quality tracks guarantee their longevity and reliability in the most rugged environments. With minimal maintenance, repair, and service costs, businesses can decrease their total ownership costs, especially when compared to traditional diesel-powered material handling equipment.

Customization and integration

Top ultra-compact electric stair climber manufacturers, such as Movex Innovation, go beyond standardized equipment to provide customized material handling solutions with hundreds of options and accessories that can be adapted to any task and environment, helping clients maximize their investments and the possibilities based on user requirements.

Examples of compelling applications for ultra-compact stair climbers

The practical uses of ultra-compact tracked stair climbers extend across multiple industries, each with distinct demands. This section outlines some key applications, demonstrating how these machines provide straightforward solutions to complex logistical challenges in material handling and transportation.

Maintenance of railways and metro stations: Ultra-compact stair climbers serve as emergency response units, capable of replacing or transporting mechanical components, signalling equipment, and emergency repair tools with agility and without disrupting daily operations.

Material handling: Tracked stair climbers facilitate the movement of heavy loads in proximity to railway tracks and within buildings, proving particularly useful in confined spaces where larger vehicles cannot operate.

Construction site logistics: On construction sites, these stair climbers transport various materials and equipment, enabling seamless movement across uneven terrain and within restricted areas, increasing the speed at which construction jobs are carried out.

Building mechanics: Electric stair crawlers are instrumental in the vertical transportation of mechanical systems for buildings, such as HVAC units, offering an ideal alternative to costly cranes, especially in urban settings with space constraints.

Industrial environments: In industrial settings, industrial stair climbers are versatile tools for transporting a variety of materials—all while maintaining operations without the need for extensive setup times.

Mining: Electric stair climbers can easily transport parts for maintenance in mines, easily navigating the limited space and contributing to uninterrupted mineral extraction activities.

Battery transportation: Models designed for heavy loads, like Movex Innovation’s TT-66, can efficiently transport large batteries and similar items, decreasing the risks associated with manual handling on stairs.

Last-mile delivery: Tracked stair climbers are game-changers in the last-mile delivery chain; delivery staff can safely bring goods to locations that are otherwise difficult or dangerous to access.

Ultra-compact tracked stair climbers are transforming material handling processes for the better. These machines offer a versatile and economical solution to the challenges of moving materials in complex and confined spaces. While they have a broad range of applications, it is the combination of safety, customization, and cost-effectiveness that stands out, making them a valuable asset in industries looking to enhance productivity without compromising on safety or negatively impacting their bottom line.

Want to learn more about our ultra-compact tracked stair climbers ?

Reach out to Movex Innovation’s material handling experts today

READ OUR LATEST CASE STUDIES AND NEWS