Don’t let equipment pricing blind you Why Movex Innovation’s material handling equipment is the investment you need to make right now

Written by William Nicholls | November 5th 2024

Let’s cut to the chase: running a material handling job isn’t cheap. Costs pile up fast—labor, lost production, maintenance, safety, insurance, downtime, fuel… you name it.

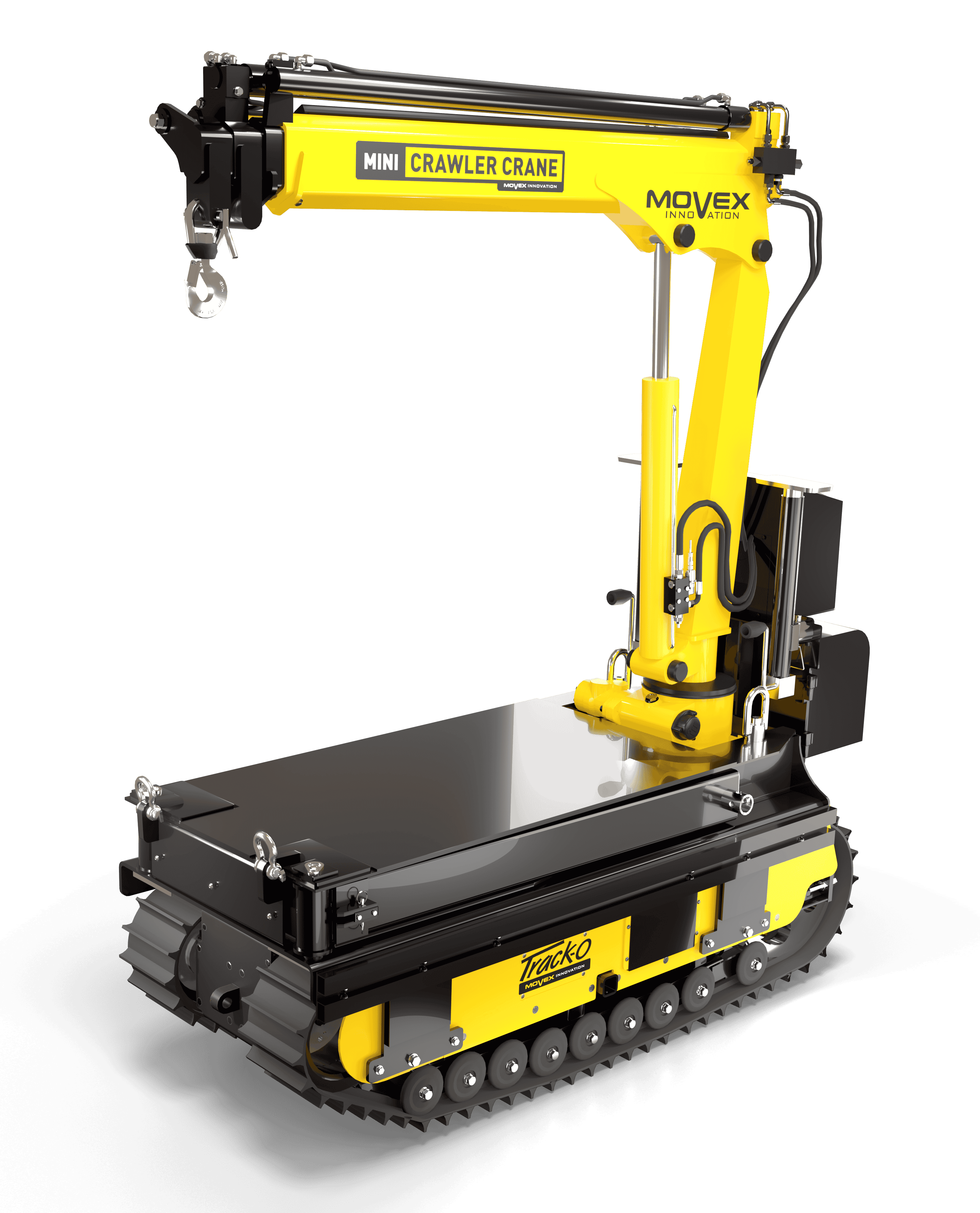

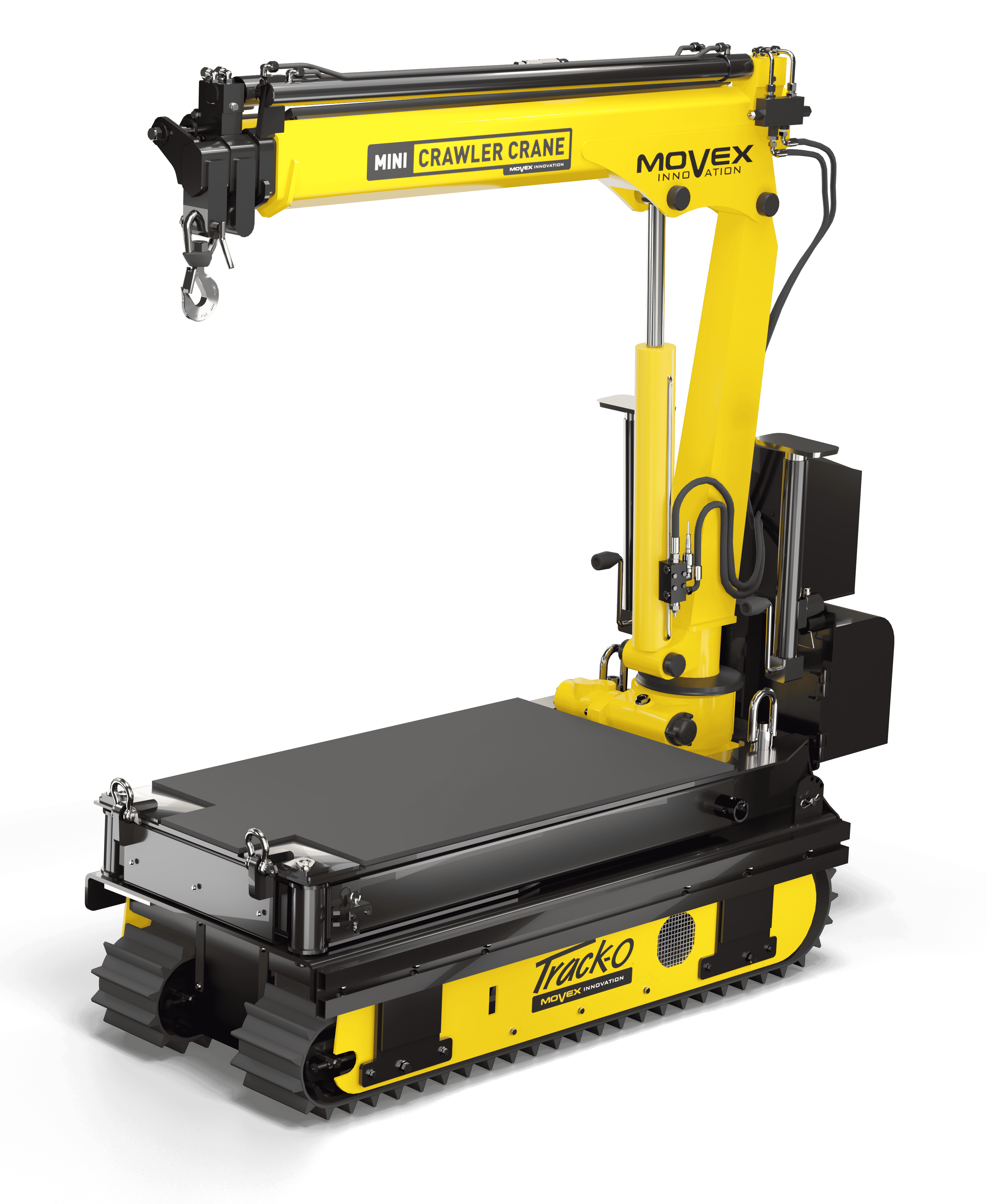

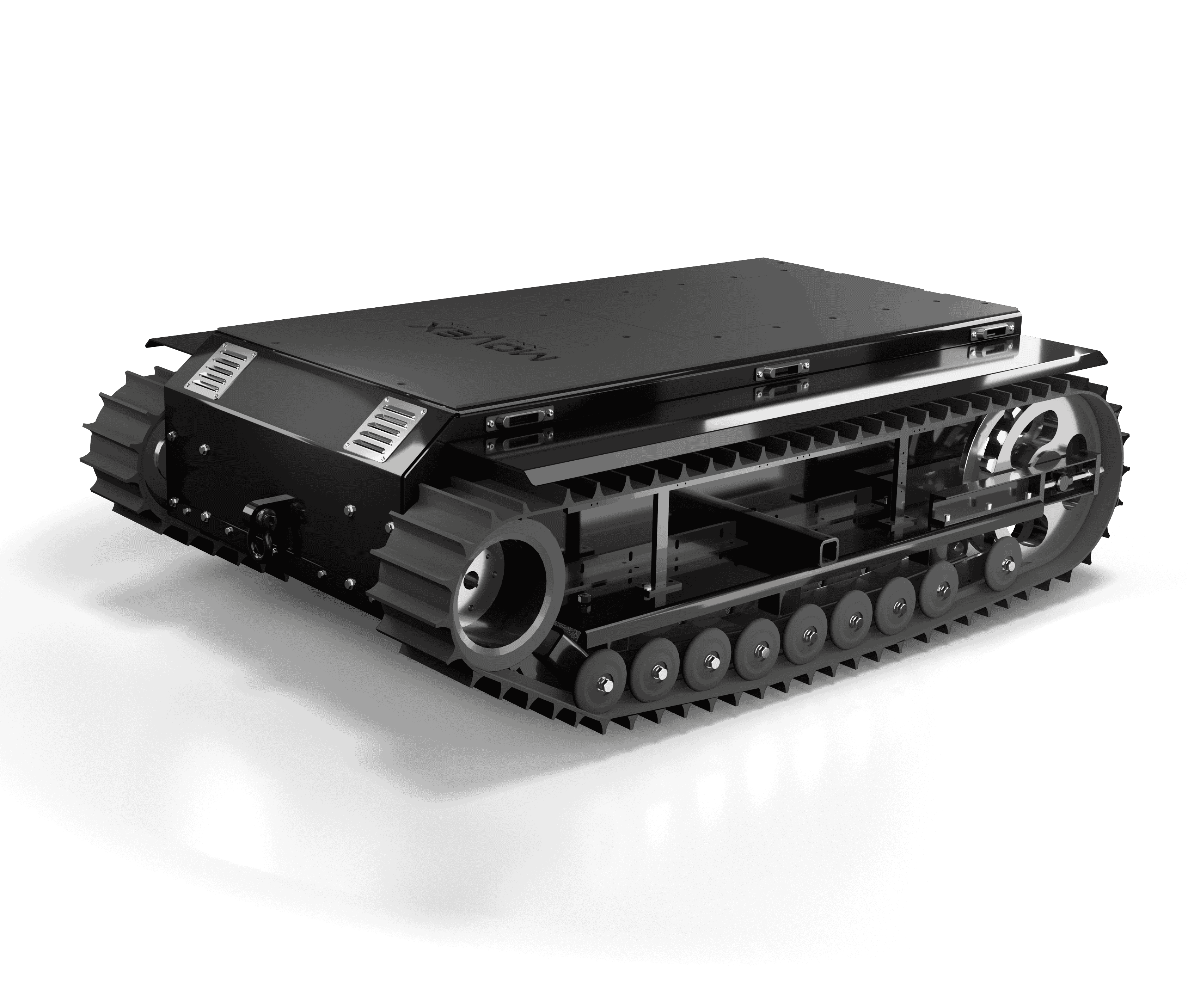

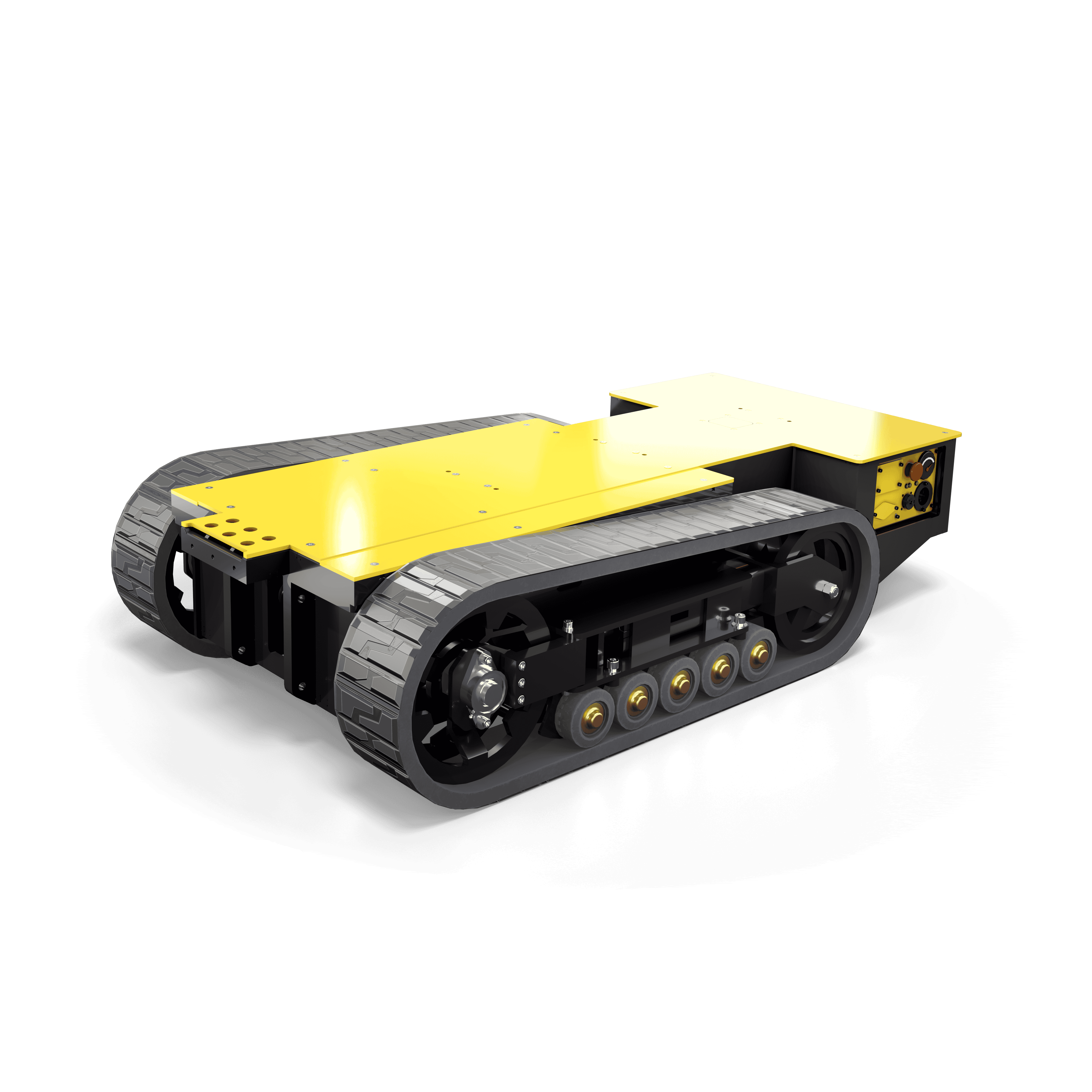

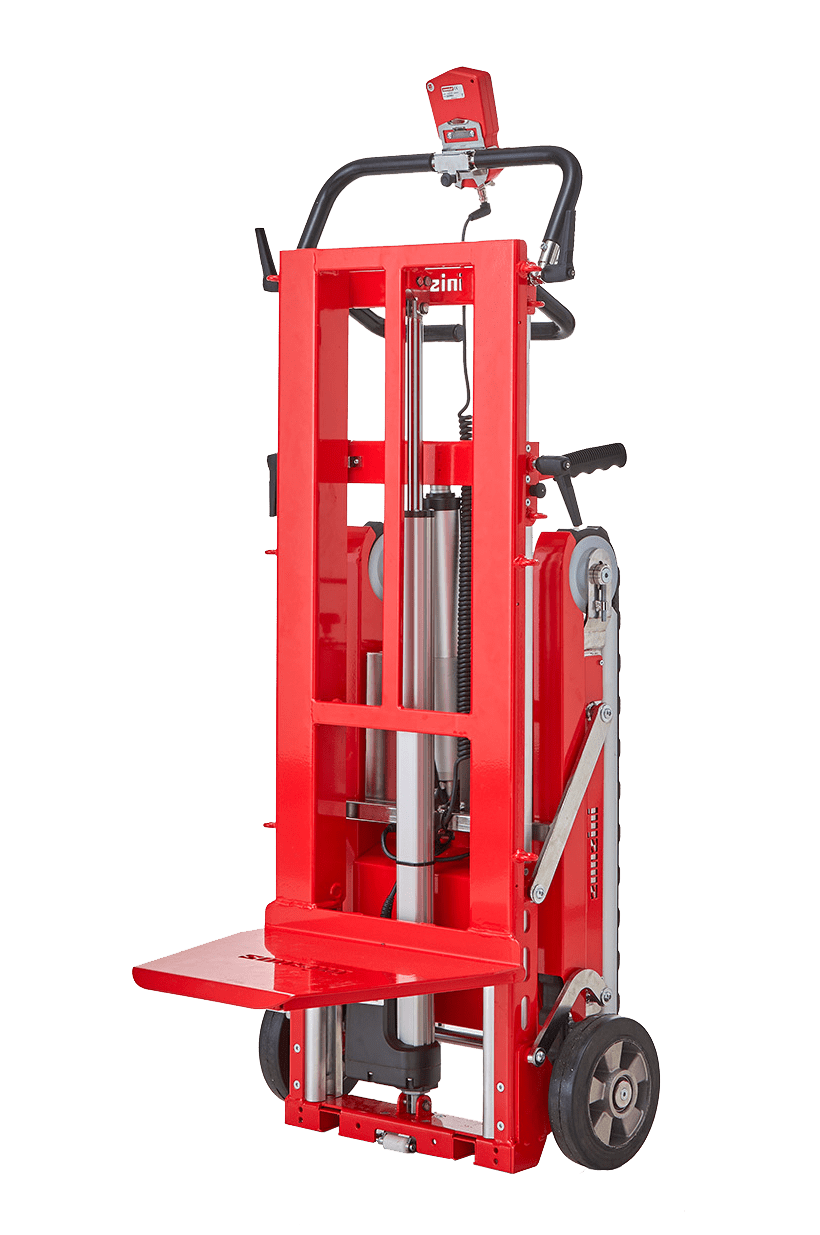

So, when the price of new material handling equipment comes up, it’s only natural to feel a bit of sticker shock. But here’s the reality: if you only look at the sticker price, you’re missing the bigger picture. You’ve got to do the math because Movex’s 100% electric, ultra-compact material handling equipment is built to save you money over time.

This is more than just a purchase—it’s a strategic move that will turn your material operations into a lean, green (read: cost-effective) machine. Let’s break down exactly how our material handling equipment helps you save and why it’s worth every penny.

Health and safety savings: Keep your team strong and your wallet full

Injuries cost money—no two ways about it. Between medical bills, potential legal troubles, and lost manpower, workplace accidents are a major drain. Movex’s material equipment minimizes these risks by taking on the heavy lifting and dangerous tasks, keeping your team safer. Fewer injuries mean fewer payouts, fewer days lost, fewer recruitment headaches. Plus, a safer crew is a happier, more productive one.

Prove your operations are safer, and say goodbye to ballooning insurance premiums

Insurance costs can drain your budget fast, especially if your operations involve risky, labor-intensive tasks. But there’s a simple truth: the safer your operation, the lower your insurance premiums. Movex Innovation’s material handling equipment is engineered to reduce injury risks by taking on the tough jobs, allowing your crew to operate from a safer distance. Insurance providers recognize this reduction in risk, which strengthens your case for negotiating lower premiums. With reduced incidents and claims, your business profile improves, leading to better insurance rates and long-term savings.

Slash labor costs: Less mundane work, more results

Manual labor is expensive, especially when workers are tied up with non-value-added tasks. Movex’s remote-controlled equipment takes over the grunt work, freeing your crew for upskilling and higher-impact roles. With fewer hands needed for the hard stuff, you curb labor hours and overtime, saving big. It’s about getting more done with fewer resources, all without burning out your team. When given more appealing responsibilities, your staff will be more likely to experience better job satisfaction and avoid jumping ship.

Speed up operations: Get more done, faster

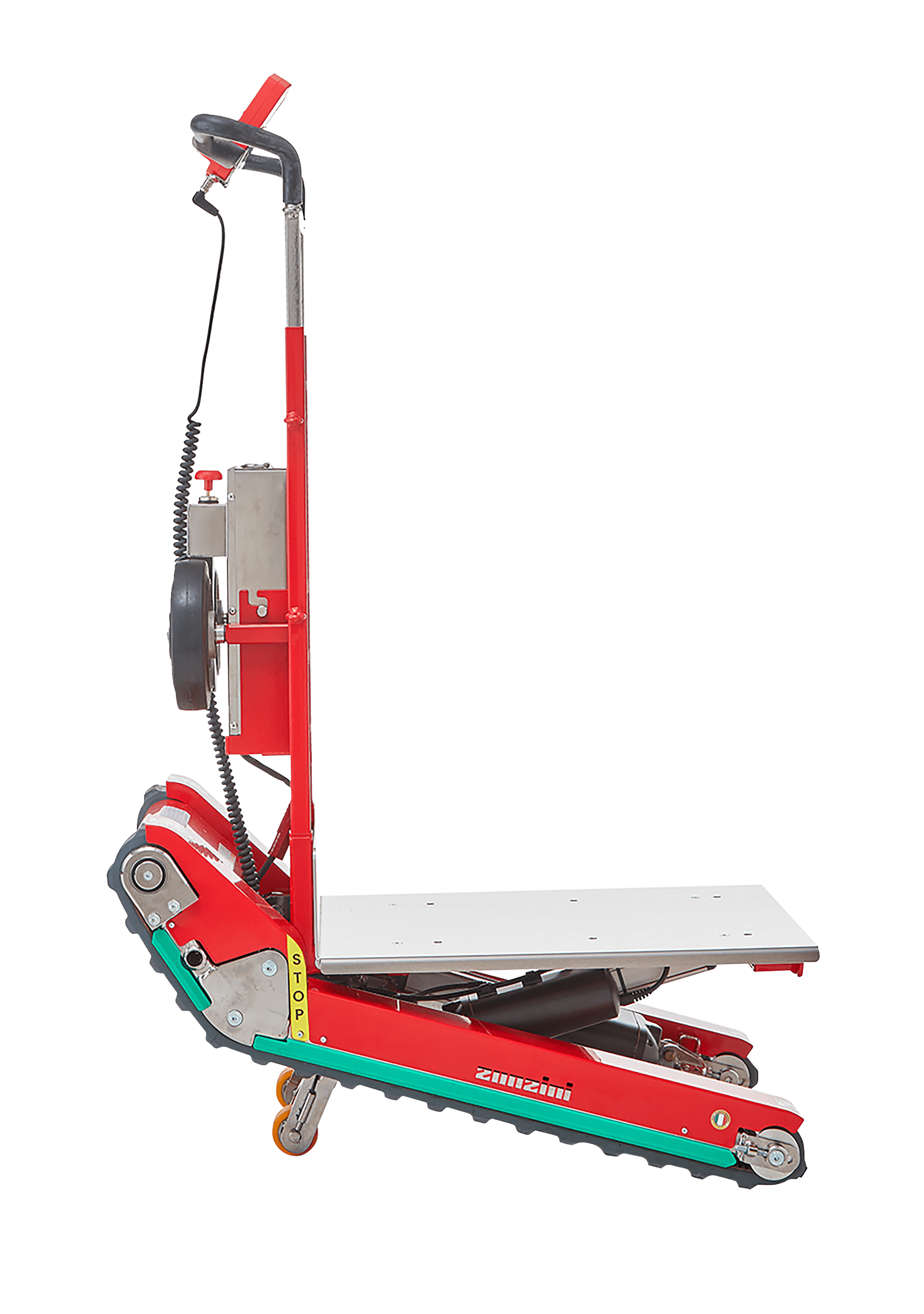

Time isn’t just money. It’s everything. Movex’s ultra-compact compact, electric-powered machines are built for speed and ruggedness, whether it’s moving heavy loads up stairs, navigating tight spaces, or tackling rough terrain. It’s a far cry from conventional techniques like using hand trucks with wheels or buggies or even employees with cumbersome straps. This efficiency allows you to finish jobs faster, which drives down costs and boosts profitability. The faster the job gets done, the faster the money rolls in.

Reduce maintenance expenses: Electric equipment is lower to operate cost

Maintenance is a silent killer of profits. Traditional fuel-powered machines have more moving parts, which means more maintenance. In contrast, Movex’s electric equipment is designed for low upkeep. Over 50% fewer mechanical parts moving parts, less breakdown, and less downtime mean reduced maintenance costs. And with remote operation, there’s less chance of operator error, further slashing repair expenses.

Eliminate fuel costs: Power up, don’t fuel up

Fuel is unpredictable and can be hard to budget for, especially with fluctuating prices. Did you know that fuel accounts for more than 40% of total costs in some sectors, like the mining industry? But with Movex Innovation’s electric material handling equipment, fuel costs are zero. Yes, zero. That’s not just saving money—that’s reducing a whole category of expenses. With electric power, your costs are stable, predictable, and way more manageable.

Train faster, deploy faster: Simple controls, faster payback

One of the biggest setbacks with traditional material handling equipment is the long training curve. Weeks of training mean more downtime, higher costs, and slower results. But that’s not the case with Movex Innovation. Our next-generation material handling equipment features intuitive, easy-to-learn controls, allowing operators to get hands-on quickly. This means you’re not spending excessive time (or money) on training programs. The faster your crew is trained, the sooner you’re seeing results on the ground. This immediate deployment accelerates productivity, putting your investment to work almost instantly.

Maximize uptimes and throughput

In some sectors, like mining, clearing material under conveyor systems often means halting production—an incredibly costly undertaking that can result in up to tens of thousands of dollars lost in output per hour. It’s enough to make any CFO panic. Movex Innovation’s compact material handling equipment is designed to operate in tight spots while other equipment is still running. You read that correctly. No more downtimes here. More uptime equals more output, fewer delays, and happy customers.

Reduce security costs: No extra infrastructure needed

Big, bulky equipment needs extra security measures—guards, fences, cameras, security personnel, you name it. It all adds up. Movex Innovation’s compact design means you can store it securely in smaller areas, cutting down on the need for security infrastructure. Less security means lower costs, plain and simple.

Fuel-propelled equipment is not future-proofed

Fuel-powered machines are outdated and simply not built for the future. Movex’s electric, industry 4.0-ready equipment is set up for next-generation technology, with CAN bus interconnectivity that opens the door to autonomous and AI-driven operations. As industries move toward automation and intelligent systems, sticking with fuel-driven equipment means you’re already falling behind.

In conclusion, when you do the math, it’s clear that Movex Innovation’s material handling equipment offers a lower total cost of ownership (TCO) than traditional alternatives. From boosting productivity to slashing operating costs, this investment doesn’t just pay for itself—it drives long-term profitability. It’s not about the price you pay upfront—it’s about the savings you unlock over time.

Whether you are struggling with moving loads up and down stairs, handling material in tight spaces, cleaning debris, or picking and carrying massive items, there is a better way than sticking with the status quo. Crunch the numbers. Make the smart move. And move to a new era of material handling equipment with Movex Innovation.

Interested in learning more about how Movex Innovation can support your business?

READ OUR LATEST CASE STUDIES AND NEWS