Revolutionizing Material Cleanup: A Modern Approach to Material Handling in the Mining Industry

Written by William Nicholls | August 9th 2024

In the demanding mining and quarrying sectors, overall efficiency hinges on the performance of every single process. A critical, yet often challenging, component of material handling in the mining industry is material cleanup. The way operations manage spillage from crushing and conveyor processes directly impacts output, profitability, and worker safety.

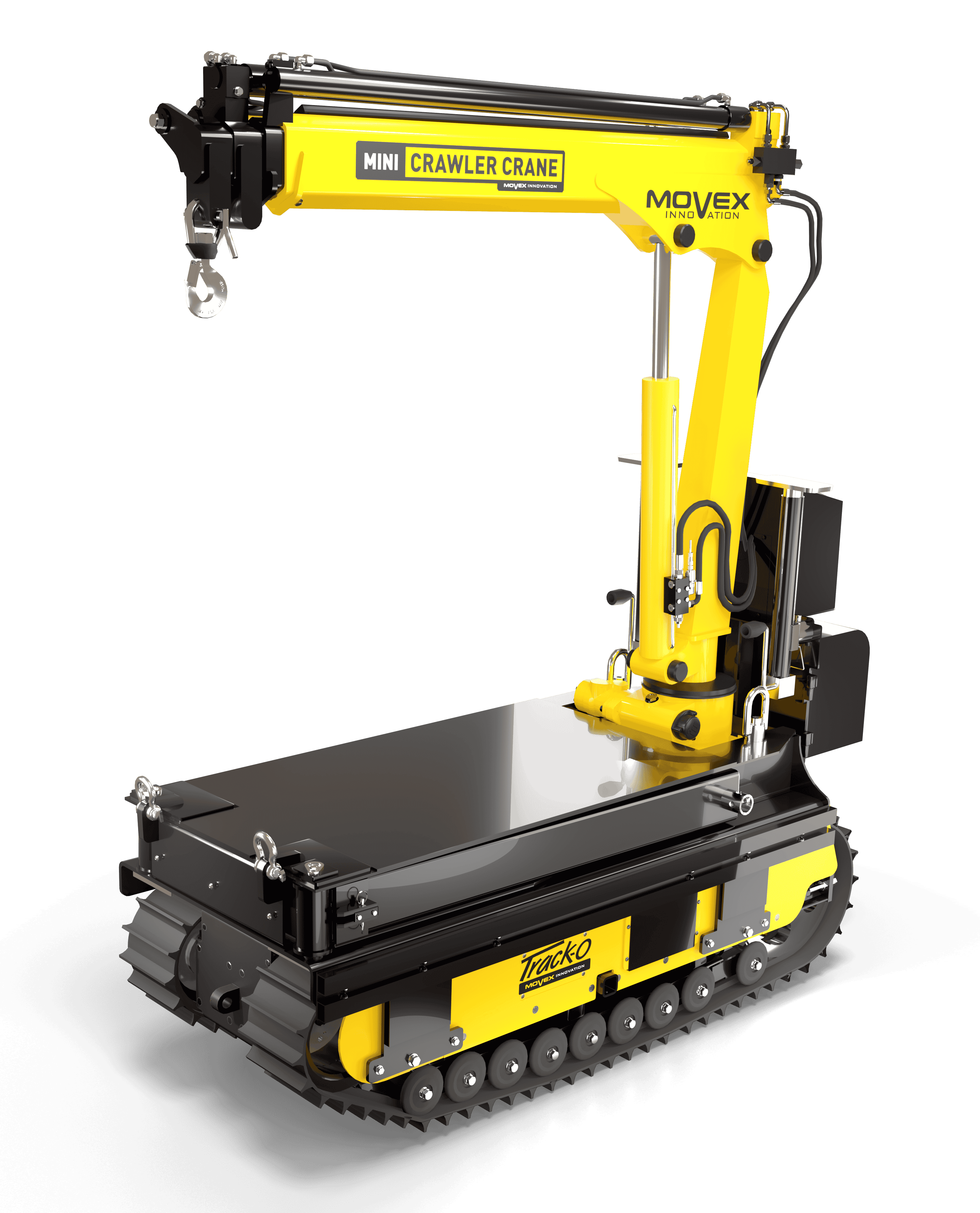

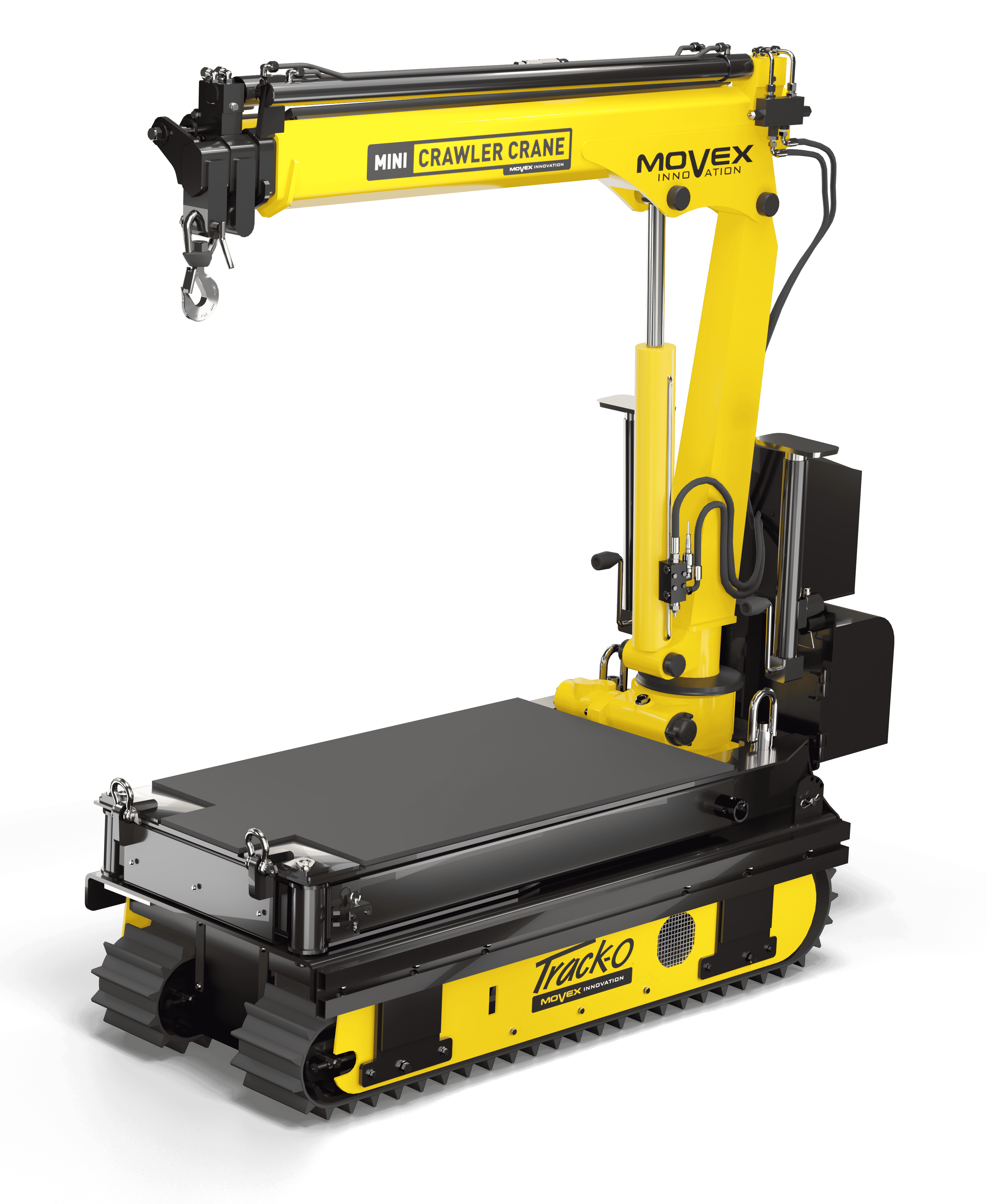

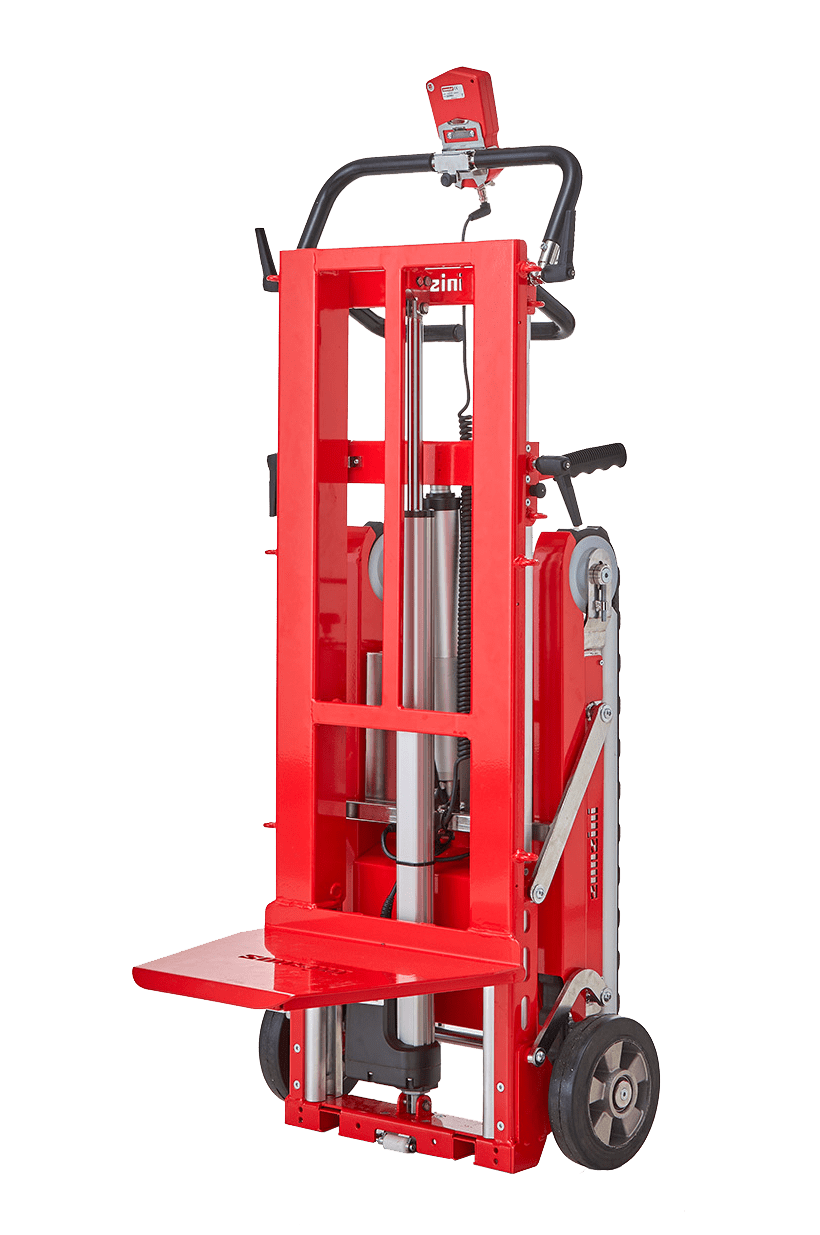

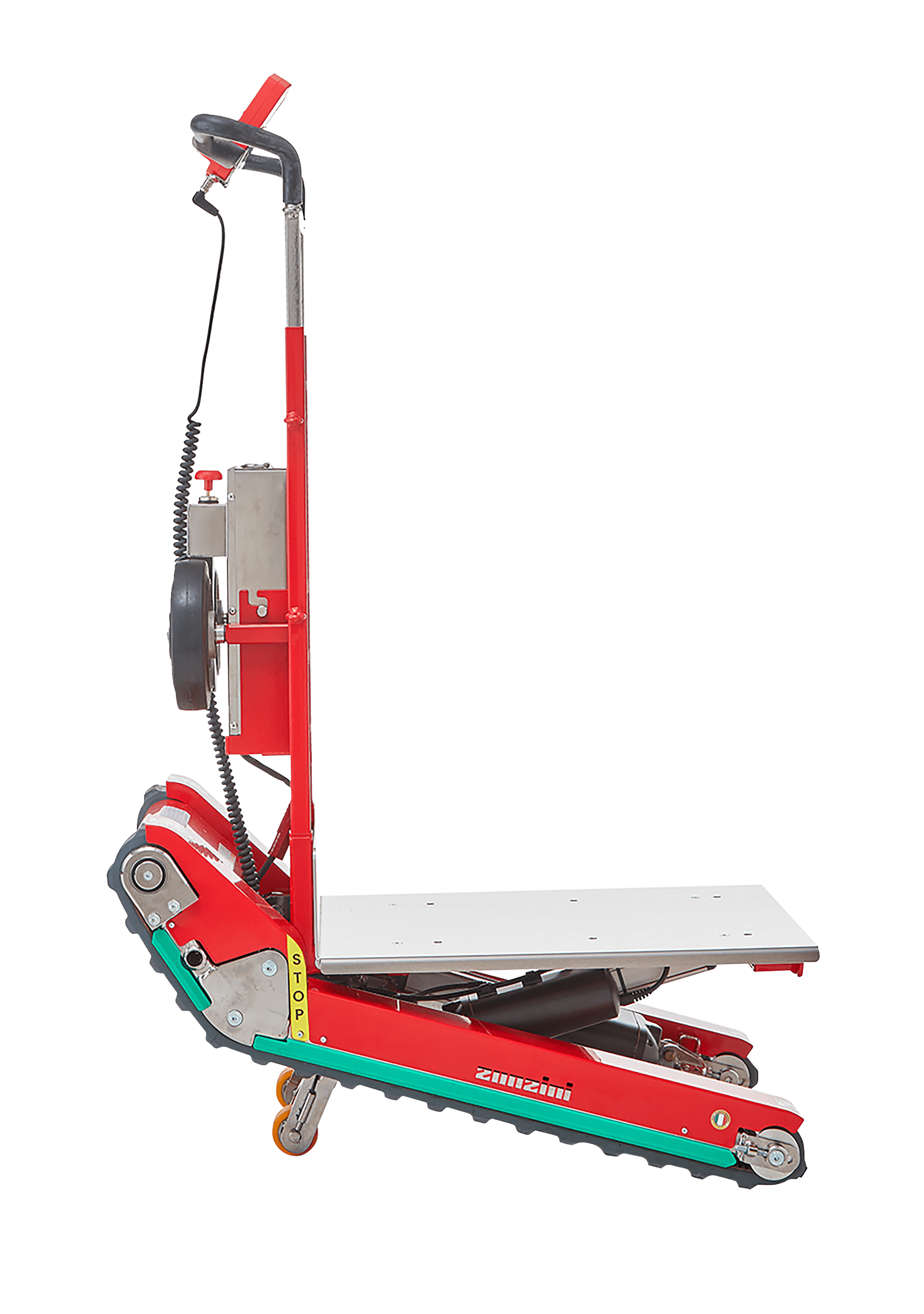

For decades, traditional methods for spillage removal have been a source of frustration. Today, significant innovations in specialized mining material handling equipment, like Movex Innovation’s ultra-compact mini loaders MINIDOZER line of ultra-compact mini loaders, are finally providing a definitive solution to these costly cleanup problems.

The Core Challenges of Material removal in Mining

Managing materials in mines and quarries is renowned for being difficult due to constant spillage and blockages. Conveyor systems frequently experience material overflow, particularly at transfer points. Traditionally (and still to this day!), to remove the debris, multiple employees were required to manually remove dust, rocks, and debris using shovels. This gruelling task could take hours or days because the conveyors had to be stopped so that the workers could safely carry out the material cleanup.

That meant tens of thousands of dollars lost in output each hour.

Lost productivity and costly delays

Because of constrained timelines, some maintenance teams delay the removal of spilled material beneath conveyor systems until it accumulates to the point of causing equipment breakdowns. This exacerbates downtimes to extend over several days or weeks—not to mention the unplanned costs and production delays.

Safety and hazardous conditions

Furthermore, manual handling poses safety risks, as workers operate in hazardous conditions, often in extreme heat. Musculoskeletal injuries from repetitive motions or bumping into the conveyors, slips and falls due to uneven surfaces, and exposure to potentially harmful substances inevitably lead to higher absenteeism and insurance premiums.

Ineffective and unsustainable methods

Other mining and quarry operations sometimes used water hoses; apart from being unsustainable, this technique could not be used for certain materials, like iron ore, which is typically recovered dry.

So, is there a better way than the shovel or water hose?

Limitations of Skid-Steer Loaders for Cleanup

Some mines think skid-steer loaders, also known as skid loaders, skidsteers, or SSL, are the solution. Indeed, they can be a viable alternative. But there are a couple of aspects to remember when dealing with skid loaders.

For one, many of them are still fuel-powered. With today’s gas prices, that can cause a real dent in a company’s bottom line. They also do little to reduce noise pollution—damaging workers’ health yet again—and GHG emissions.

Other companies have introduced electric and remote-controlled skidsteers, but their bulky designs make it difficult to maneuver under the hard-to-reach spaces typically found under a conveyor system. Many operate either on standard wheels or caterpillar wheels; however, in both cases, the equipment can be hard to turn in tight places, and the traction is not ideal on rugged terrains.

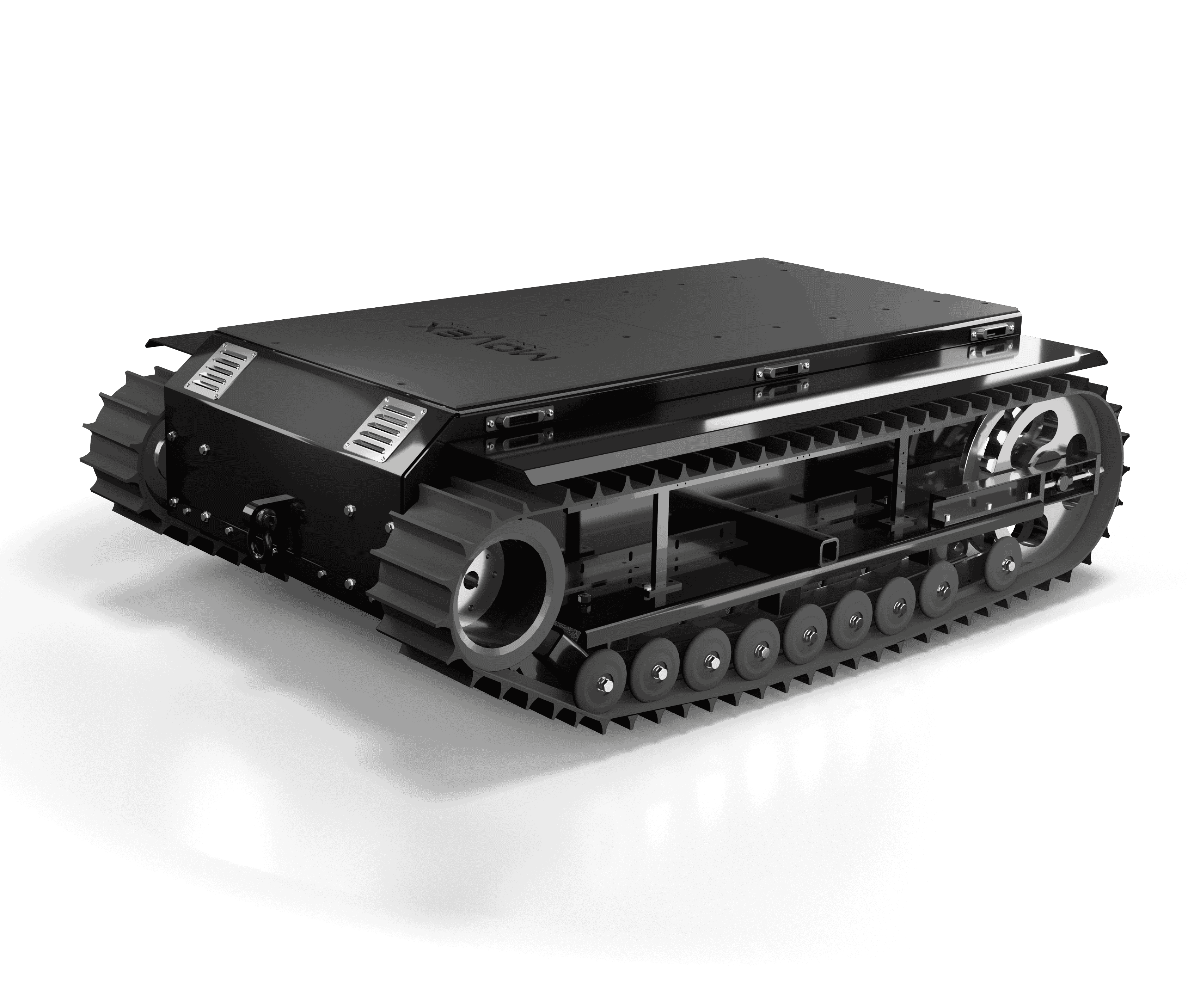

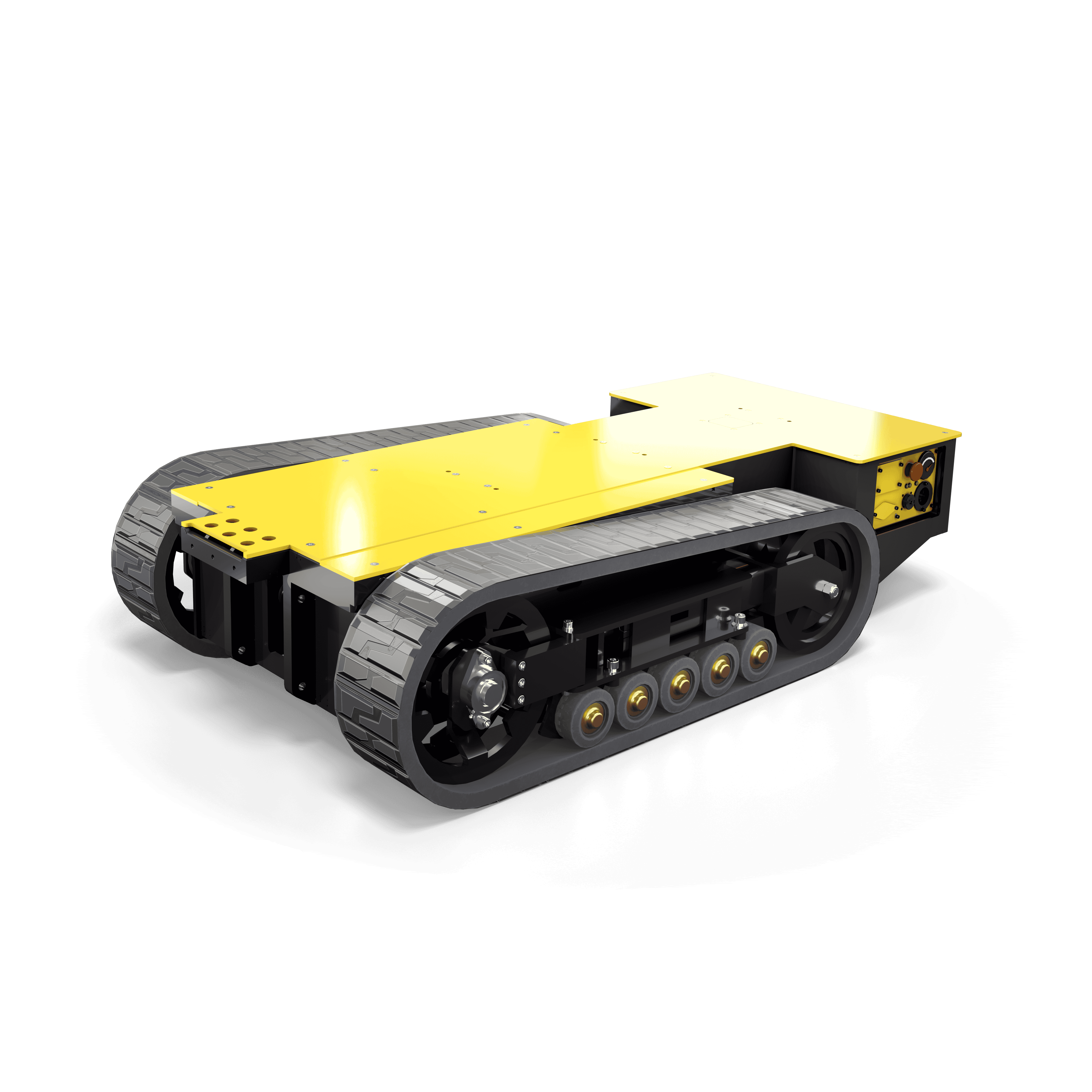

Movex Innovation’s MINIDOZERs have the lowest profiles in the industry. Mounted on caterpillars that can be independently operated, they can easily turn in narrow passages, and their grip on all types of surfaces makes them exceptionally stable.

Luckily, another proven solution on the market tackles these problems as well.

Enhancing Worker Safety During Cleanup Operations for mines and quarries

Movex Innovation’s electric, remote-controlled MINIDOZERs are proving to be game changers in finally resolving the difficulties associated with spillage removal in mines and quarries. Requiring only one operator, these MINIDOZERs can be maneuvered with a simple wireless controller with two ultra-precise and responsive joysticks—up to 300 ft. away from the conveyor systems. Another key advantage: the operator does not need to have any special certifications, making the equipment accessible and easy to use for a broader range of employees.

Their ultra-compact design allows them to operate in extremely narrow, confined spaces where other taller equipment cannot reach. In fact, MINIDOZERs can remove spillage without ever stopping the conveyor systems. Their low profiles have been specifically developed so that the machines can clean under conveyors. Featuring the biggest bucket capacity for their sizes, the operator can, therefore, safely load a high volume of material under the lowest structure.

Worker health and safety come first with Movex Innovations’ MINIDOZERs. Apart from allowing teams to ditch the shovel work, the equipment is electric, emitting zero emissions, with the added benefit of slashing fuel costs.

Battery performance levels in extreme temperatures

Concerns about battery life in extreme mining environments are valid, but the MINIDOZER is built for them.

- Runtime: It operates for up to 12 hours on a single charge.

- Additional battery packs can extend the runtime by another 12 hours, allowing the equipment to run 24/7

- Continuous Operation: Battery changes are straightforward and can be completed in just five minutes with a forklift

- Temperature Resilience: The battery technology remains reliable and effective in extreme heat and in freezing temperatures as low as -40°F.

Designed for Longevity and Low Maintenance

Service and maintenance questions often arise when mines and quarries procure new equipment. However, Movex Innovation’s MINIDOZERs are built to be maintenance-free, guaranteeing minimal downtime and hassles when properly used.

All parts are easily accessible, simplifying any untoward repairs. The company even offers remote assistance to support maintenance teams whenever needed. For those who prefer a more hands-on approach, Movex Innovation provides comprehensive training to ensure crews are fully equipped to maintain the MINIDOZERS.

Movex Innovation’s team of engineers are also ready and available to custom engineer MINIDOZERS to resolve specific material cleanup challenges.

Specialized Cleanup Applications and Proven Success

The MINIDOZER adapts to even the toughest cleanup environments.

For Aluminum Smelters: The MINIDOZER AL Series is purpose-built for the extreme conditions inside smelters. These specialized units ensure safe and efficient material cleanup where traditional equipment fails — in areas with high heat, dense airborne particles, and strong electromagnetic fields.

Engineered for durability, the AL Series:

- Operates reliably under extreme temperature fluctuations.

- Handles environments with heavy particle concentration without performance loss.

- Functions in zones with electromagnetic fields exceeding 300 gauss.

- Provides safe control with a remote operation range of up to 100 ft, keeping operators out of harm’s way.

The Future of Efficient Material Handling in Mining is Better Cleanup

By directly targeting the costly and dangerous problem of material spillage, the MINIDOZER helps operations optimize their entire handling process. Adopting advanced, purpose-built cleanup solutions is no longer just an option—it is essential for achieving new levels of safety, productivity, and profitability in a competitive industry.

Movex Innovation’s MINIDOZERs have been successfully integrated into operations by notable clients, including VALE, Rio Tinto, BHP, Kinross, and Centura Gold. These industry leaders trust the MINIDOZERs for their robust performance, reliability, and ability to address the mining and quarry sectors’ specific spillage removal.

Interested in learning more?

Ditch the shovels. It starts with Movex’s MINIDOZERS.

Designed to keep your mining operations running.

READ OUR LATEST CASE STUDIES AND NEWS