Heavy-Duty

Mining & Quarry

Material

Handling Equipment

Trusted by Leading Mining Companies Worldwide

Do you oversee operations in a mine? Are you responsible for mining maintenance, cleaning, or material-handling tasks? Then you know how much pressure there is to minimize downtime while ensuring worker safety.

For years, traditional heavy-duty mining equipment has been bulky, hard to maneuver in narrow spaces, and risky for employees. Manual tools like shovels only add to the inefficiency and physical strain on your teams.

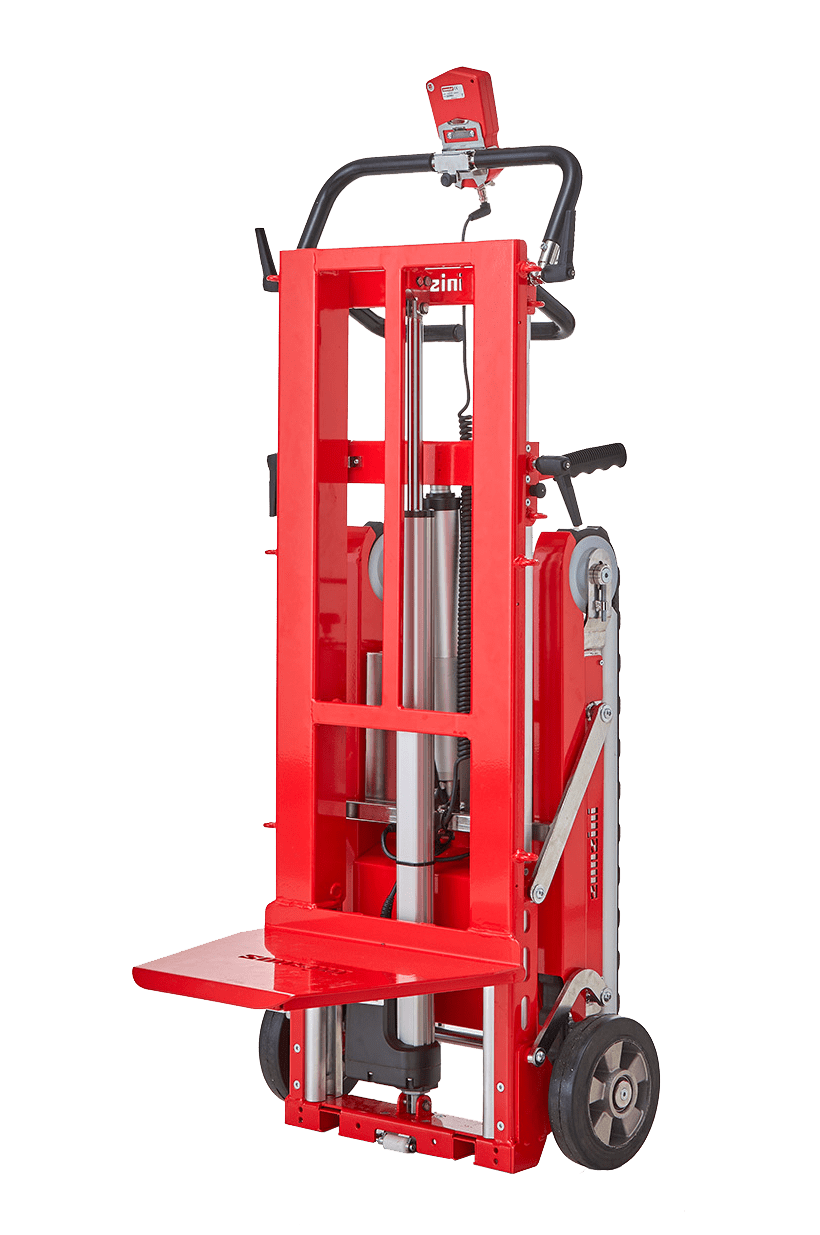

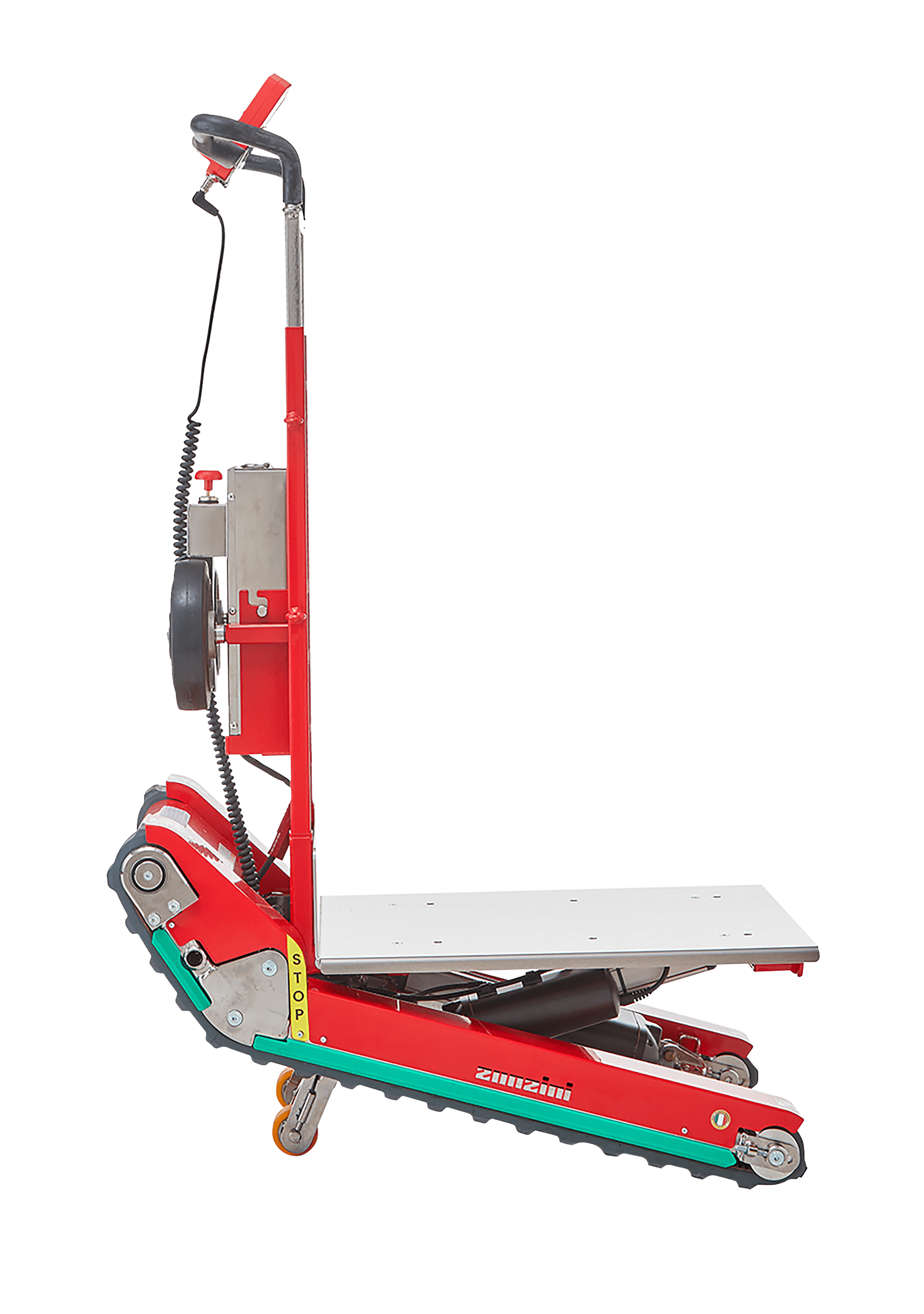

At Movex Innovation, we design ultra-compact mining material handling equipment that helps mining companies overcome these operational challenges. From conveyor cleaning in the mining industry to transportation of mining equipment for maintenance projects, our solutions improve both safety and productivity.

What if you could streamline your mining operations, reduce risks, and boost your team’s productivity, all with one piece of equipment?

Designed for your mining and metals material-handling challenges

Why choose Movex Innovation?

- Robust and reliable mining equipment

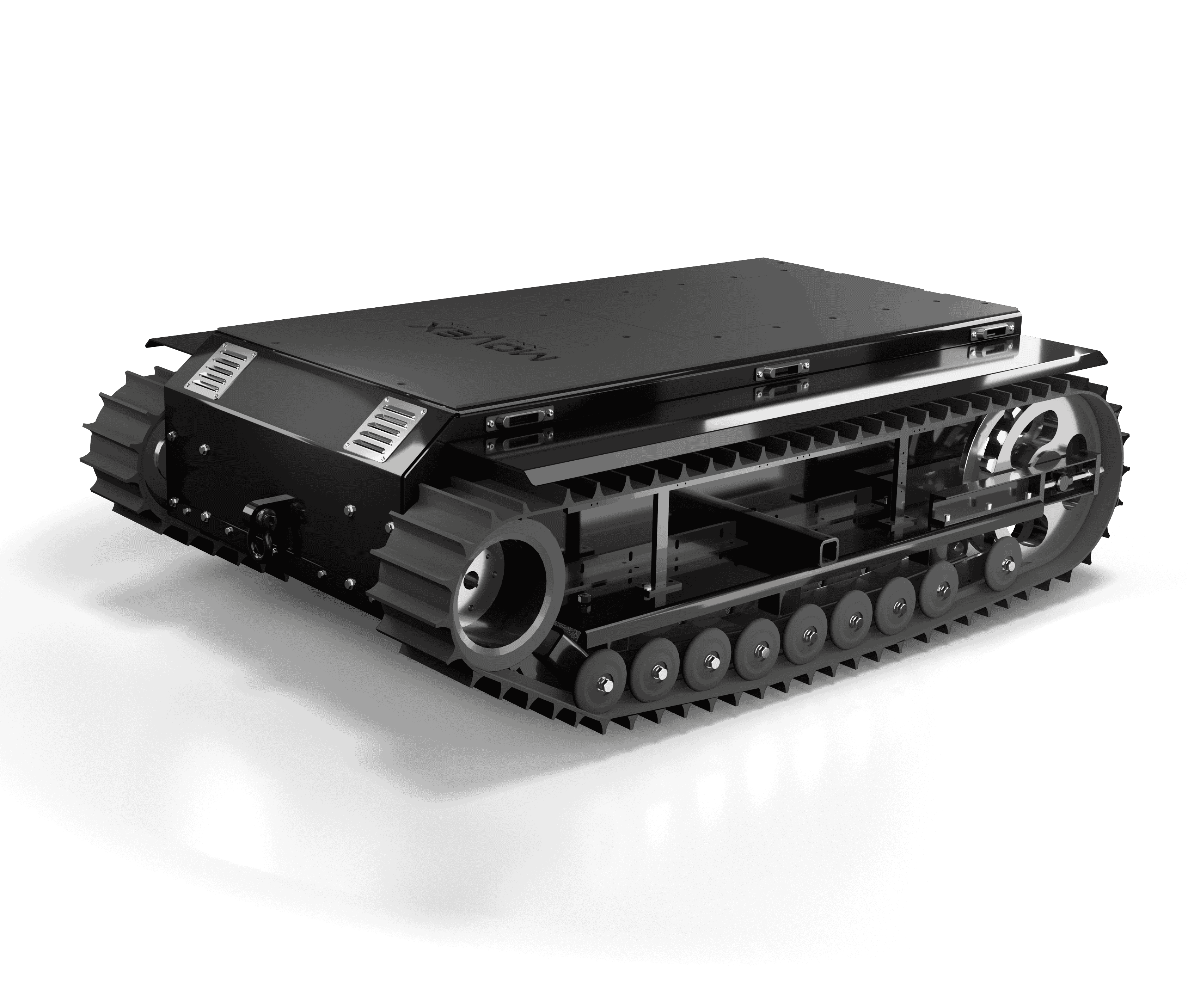

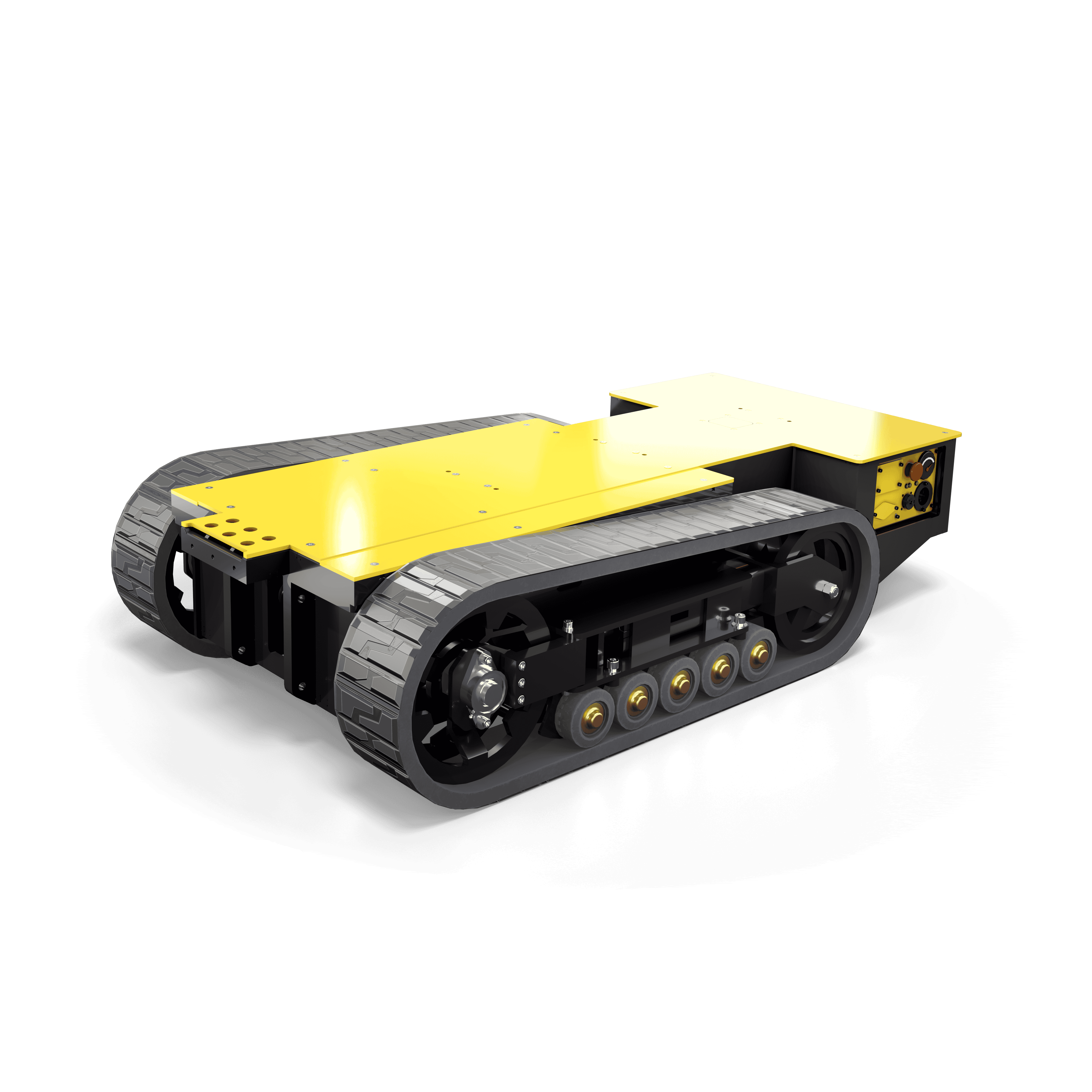

- Ultra-compact design for restricted and underground spaces

- Low-profile equipment for maximum accessibility

- Impressive bucket capacity and operation speed

- Reduced labor requirements and costs

- Decreased worker strain and risk of accidents

- Increased worker productivity and job satisfaction

- With Movex mining material handling equipment, you achieve safer, more efficient operations while ensuring long-term durability and maximizing ROI.

Frequently Asked Questions about Mining Material Handling Equipment

What is mining material handling equipment?

Mining material handling equipment refers to specialized machinery used to transport, clean, and manage bulk materials such as ore, aggregate, and overburden — as well as safely move heavy mechanical parts.. Unlike traditional heavy-duty tools, modern solutions like Movex equipment are compact, safe, and designed for confined above or underground spaces.

Why is material handling important in the mining industry?

Efficient mining material handling reduces downtime, ensures a safer environment for workers, and lowers overall operational costs. Proper handling prevents equipment damage, streamlines cleaning tasks, and boosts productivity across the mine site. For more information, you can read this article.

How is conveyor cleaning done in the mining industry?

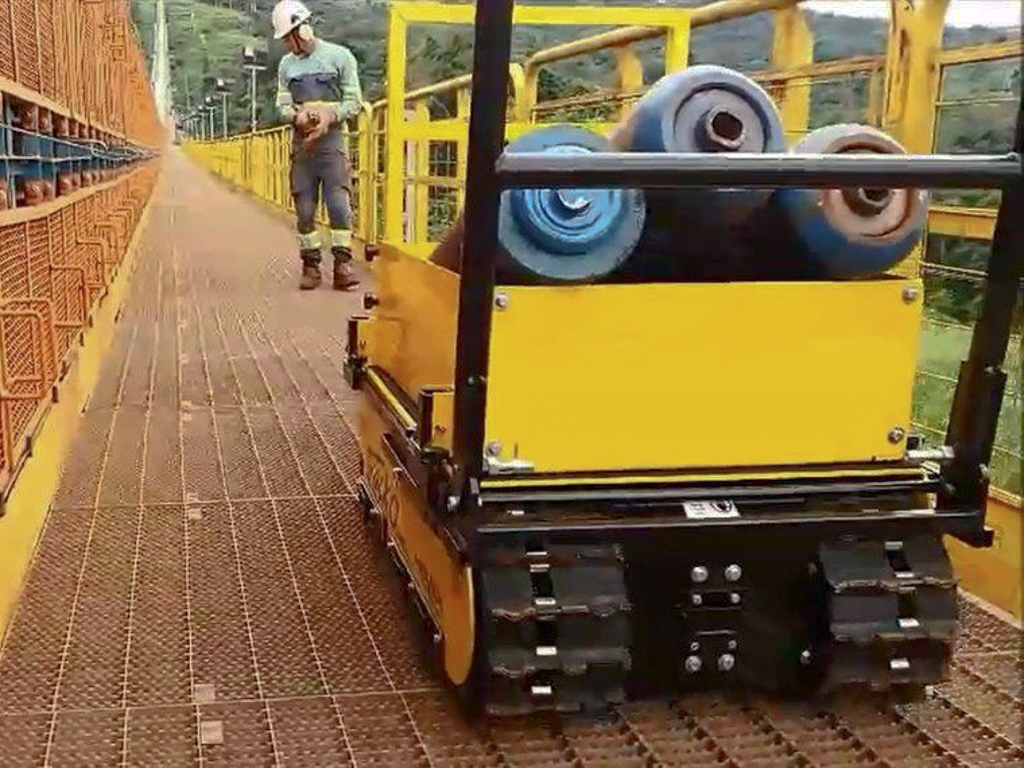

Conveyor cleaning in mining is performed using ultra-compact, remote-controlled loaders and specialized cleaning equipment that can access tight areas beneath and around conveyor systems. These machines quickly remove carryback, spillage, dust, and other buildup, keeping conveyors running efficiently. By eliminating manual shoveling, they reduce downtime, extend equipment life, and improve safety for workers.

What equipment is used for transportation in mining?

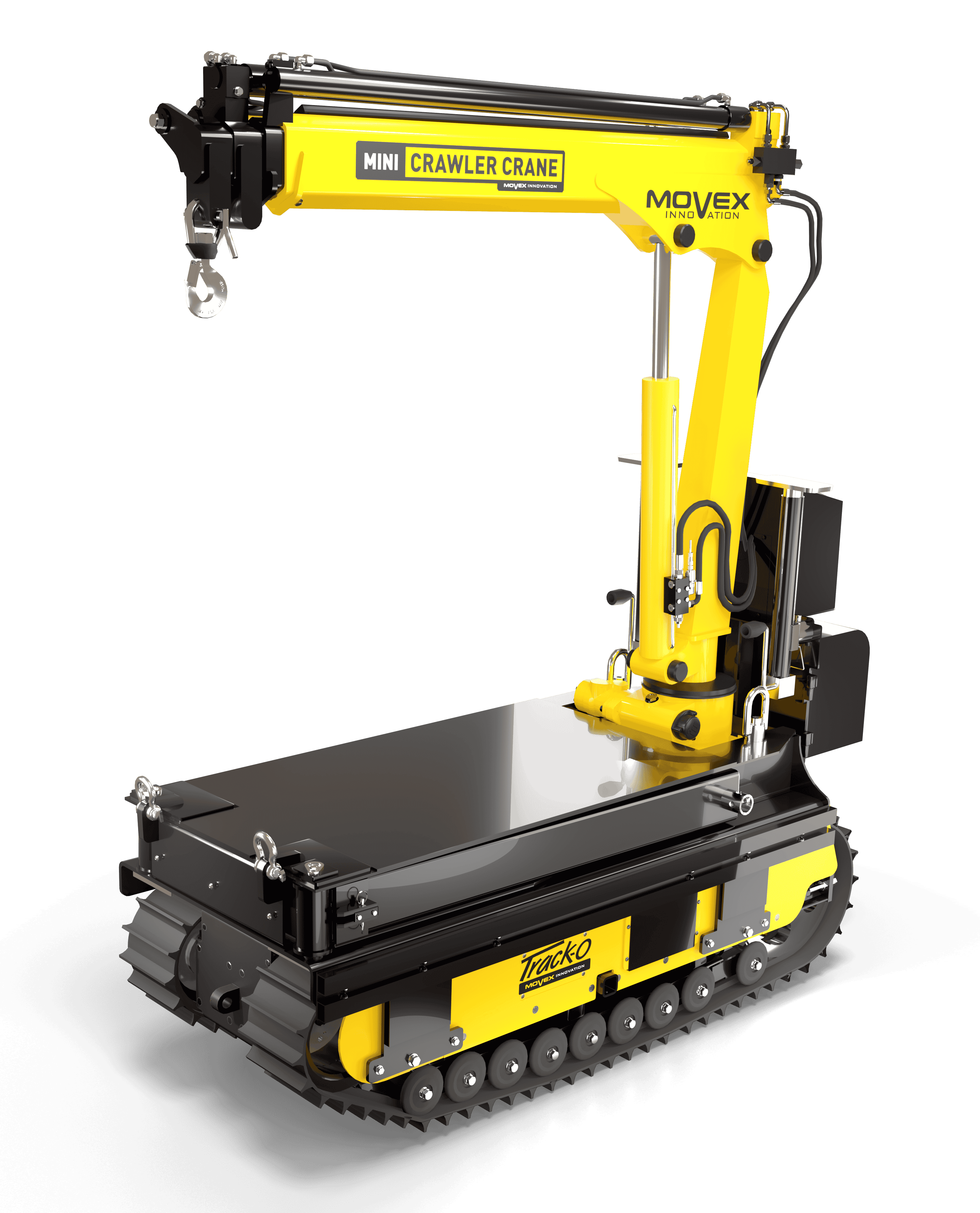

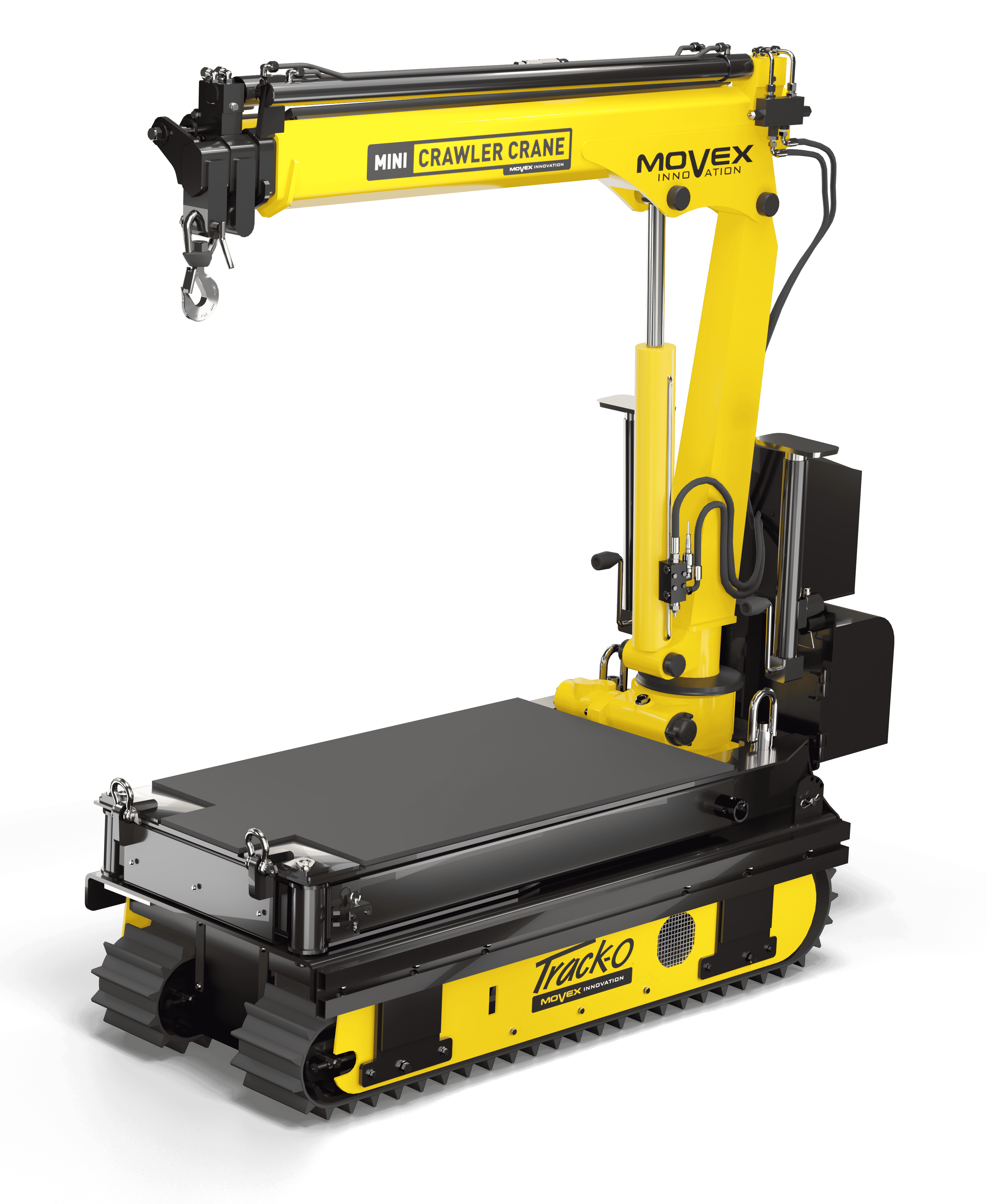

Transportation equipment in mining includes compact carriers and mini-crawler cranes engineered to safely move heavy components such as motors, bearings, and rollers. Movex machines are designed to navigate narrow and confined spaces, enabling maintenance teams to transport parts efficiently without additional manpower or safety risks.

How does Movex equipment improve worker safety?

Movex equipment reduces or eliminates the need for manual shoveling and heavy lifting in mining operations. By minimizing physical strain and lowering accident risks, it helps create a safer work environment while streamlining repetitive cleaning and transportation tasks. With the Movex MINIDOZER, workers can even clean under operating conveyors remotely—improving safety without downtime.

Read our latest case studies and news

Need more information on our ultra-compact remote-controlled equipment?