Heavy-Duty

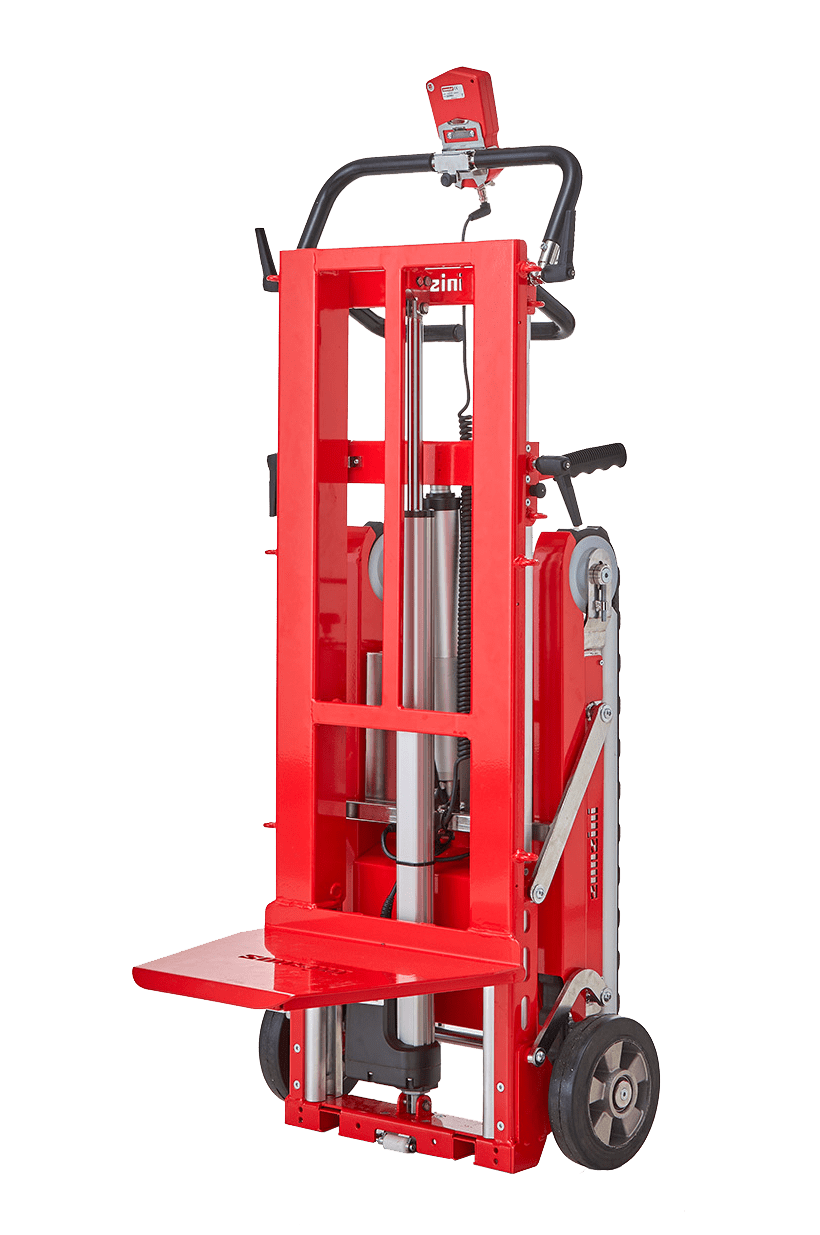

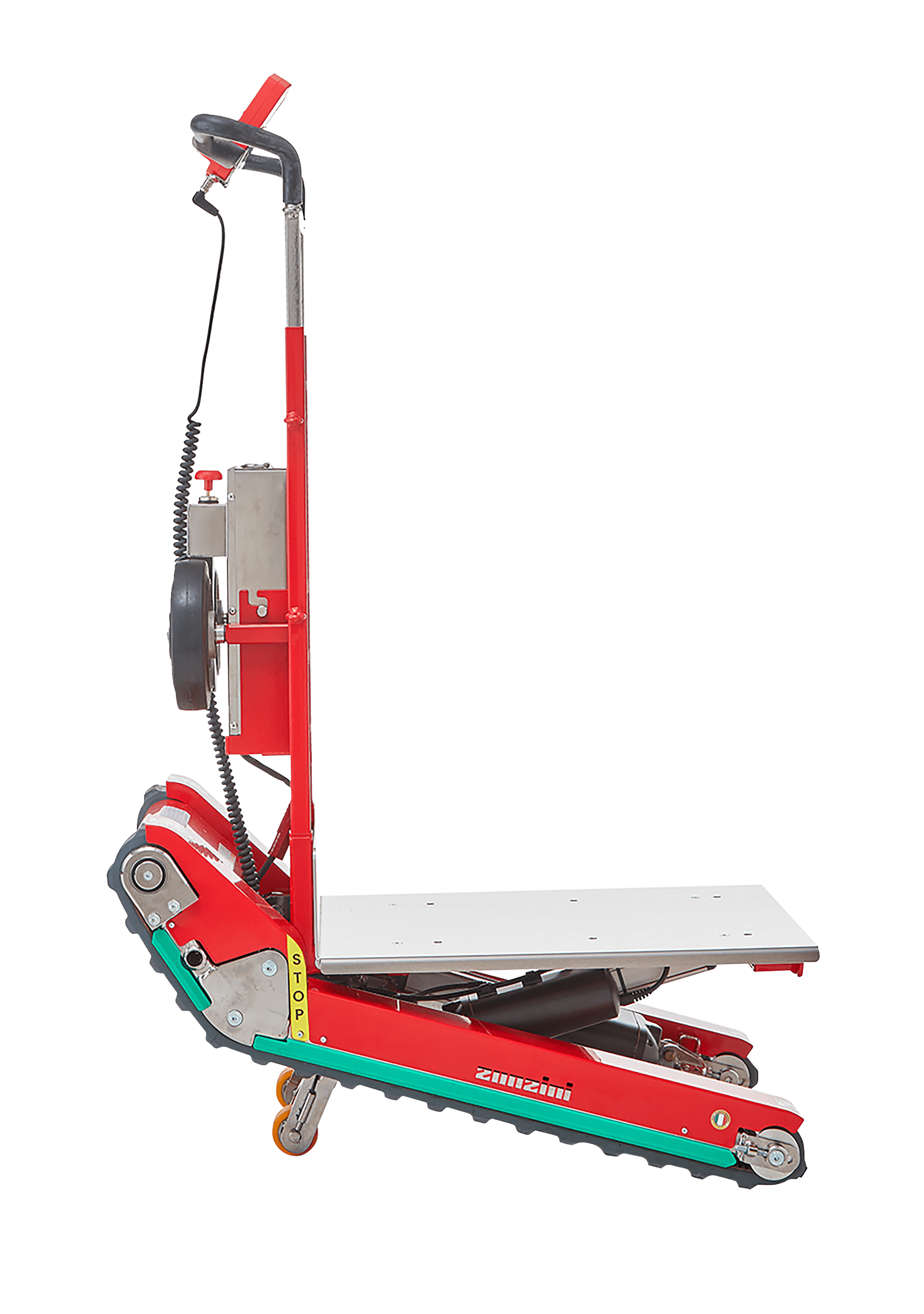

Material-Handling Equipment

for

Tunnel & Culvert Cleaning

Trusted by Leading Departments of Transportation Worldwide

Are you in charge of cleaning out and maintaining water and storm infrastructure that includes box culverts, pipes, and tunnels? Is removing sediments and debris a challenge? Do your workers struggle with manual tools in hazardous, wet, and muddy conditions to prevent flooding?

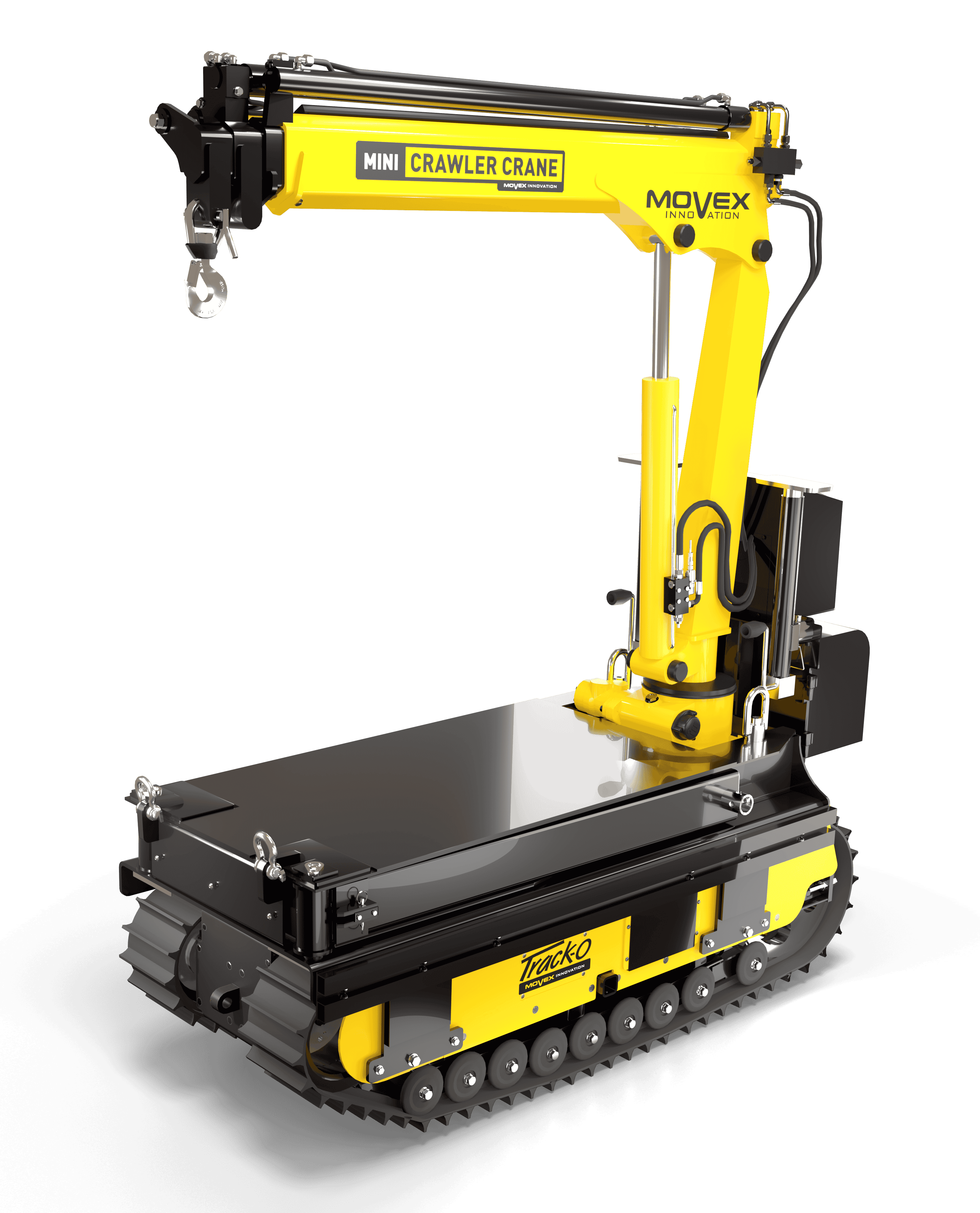

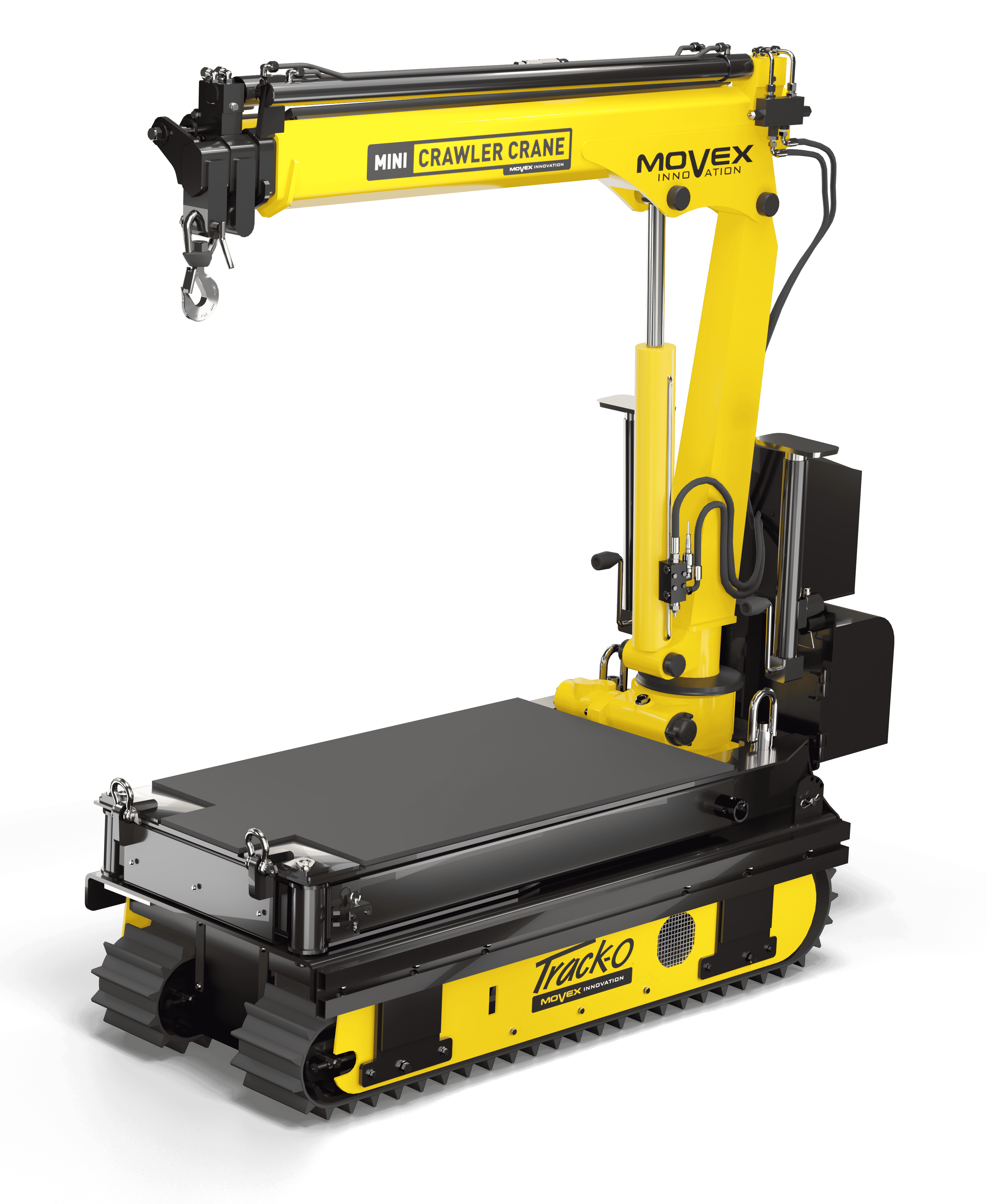

Movex Innovation’s box culvert cleaning equipment and tunnel material-handling solutions feature very compact designs with low profiles that make culvert cleaning a breeze without sacrificing operator health and safety.

What if we could help streamline your operations with a state-of-the-art culvert cleaning machine and boost your team’s productivity?

Designed for your box-culvert and tunnel material-handling challenges

Why choose Movex Innovation?

- Low total cost of ownership

- Most efficient & effective culvert cleaning equipment

- Compact for access to most culverts

- Reduced required labor & labor costs

- Decreased worker effort & risk of accidents

- Improved worker productivity

- Zero emissions

When compared to manual labor or diesel machines, Movex equipment reduces physical strain, increases safety, and optimizes culvert cleaning operations.

Frequently Asked Questions about Culvert Cleaning Equipment

What features should you look for in equipment designed for box culvert and tunnel cleaning?

Box culvert and tunnel cleaning equipment should offer:

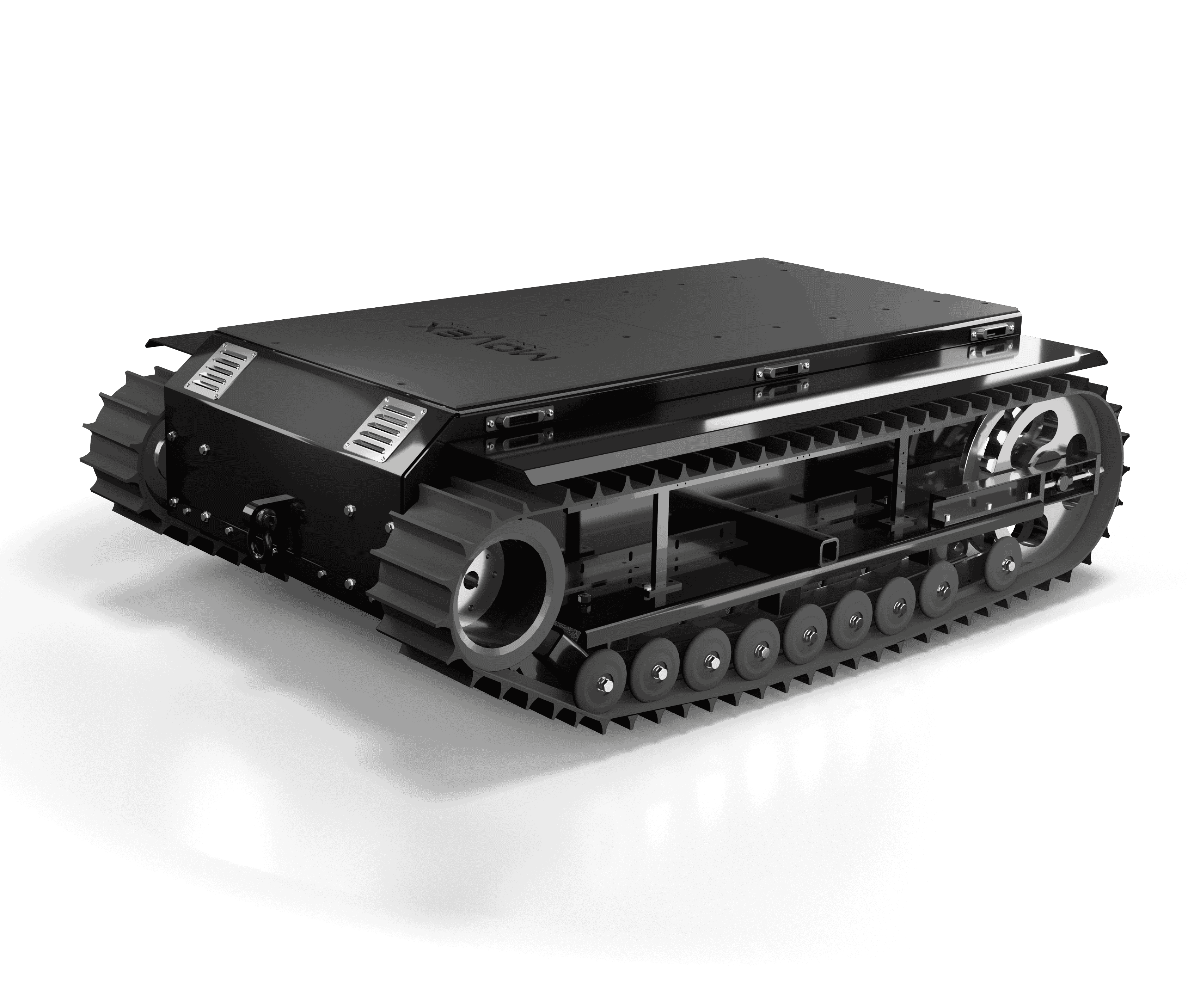

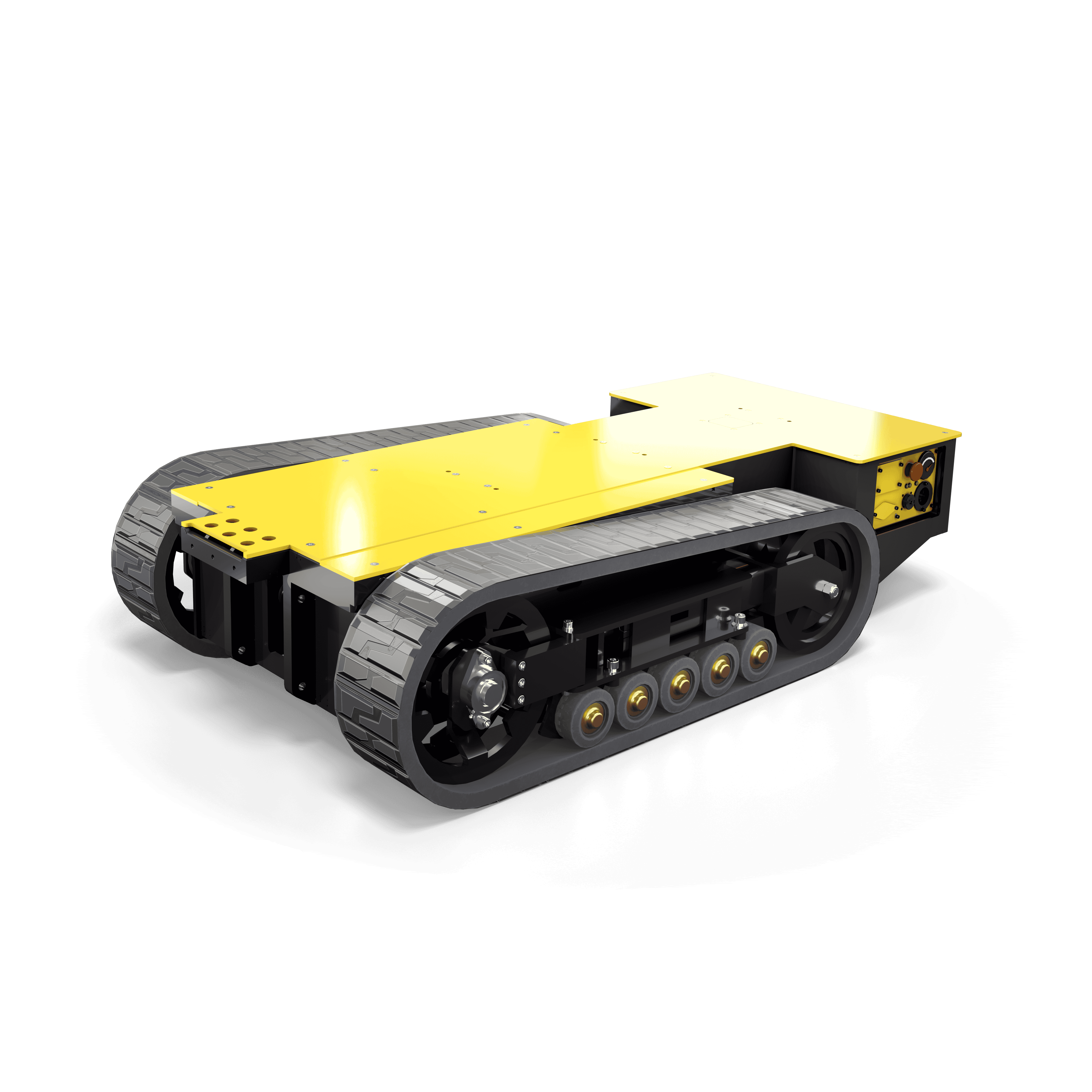

- Ultra-low (up to 22.5 in.) profile and compact size to access tight culverts and tunnels without damage.

- Remote-controlled maneuverability with precise steering for safe operation where visibility is limited.

- Strong traction and stability on wet, slippery, or uneven surfaces.

- Adequate lifting and pushing force to handle sediment, debris, sludge or silt accumulation.

- Durable, corrosion-resistant construction designed for abrasive and wet conditions.

- Enhanced safety by keeping operators outside hazardous areas, up to 300+ ft. away.

How to choose between different sizes and lifting capacities?

Choosing the right size and lifting capacity depends on:

- Culvert or tunnel dimensions – Height, width, and any bends or obstructions determine which profile fits.

- Material type and volume – Dense or heavy debris (stones, compacted mud) may require higher pushing force, while lighter silt or sludge can be handled with smaller models.

- Cleaning frequency – Routine cleanings often suit compact equipment, while infrequent heavy cleanouts may call for a larger machine.

- Access and transport – Consider how the unit will be lowered or staged at the worksite and if space is restricted.

- Operational needs – Our all-electric drive reduces maintenance and emissions while providing consistent performance in confined spaces, when diesel engines may offer more power.

How to maintain the MINIDOZER to ensure long service life?

- Clean after use – Rinse off mud, silt, and debris to prevent abrasion or corrosion.

- Inspect and replace wear parts – Check tracks, wheels, and seals regularly; replace worn parts before failure.

- Lubricate moving parts – Keep joints and mechanical points properly greased.

- Care for the power system – Recharge batteries according to guidelines and avoid overloading.

- Store properly – Keep in a dry, sheltered area when not in use to protect electronics and batteries.

- Schedule periodic service – Have a technician inspect safety-critical components and electrical systems.

Need more information on our ultra-compact remote-controlled equipment?