When Mining Conveyor Belts Stop: Moving Materials Smarter in Mining

Written by William Nicholls | November 26th 2025

The low rumble of a conveyor belt is a sound every mine manager knows well. It means the ore is being pumped out, crews are on schedule, and production targets are within reach. When that sound fades, everything changes. Equipment stands idle. Operators wait. Costs rise by the minute.

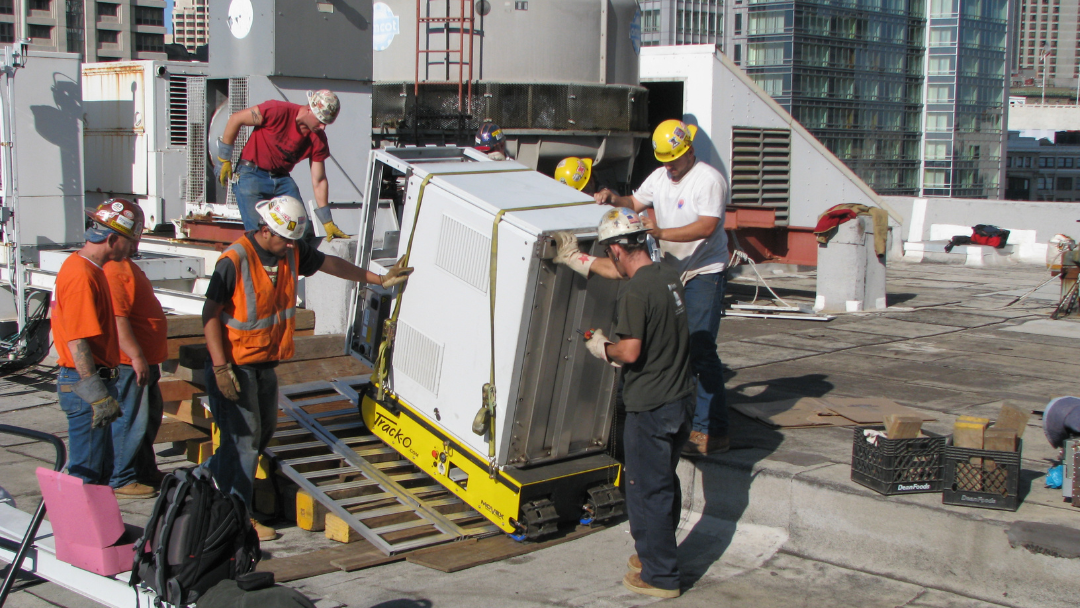

A belt breakdown doesn’t make headlines, but it can stop an entire operation. One damaged section, one seized roller, and tons of loads are left stranded underground or on an incline with no way out. The challenge isn’t only technical. It’s logistical, environmental, and human. Getting the right tools to the right place fast determines how long production stays offline.

The reality behind belt downtimes

Conveyor belts are built to withstand demanding environments, but even the most durable systems face extreme conditions. Heat, dust, vibration, and heavy impacts slowly erode components that are under constant stress. Maintenance schedules help, but mines rarely operate under ideal circumstances. Terrain complicates access, weather affects reliability, and mechanical fatigue accumulates over time.

When a belt fails, maintenance teams must transport large, cumbersome parts, like motors, gearboxes, and belt rolls, through spaces where trucks cannot go. In open-pit mines, rough terrain and steep grades make each intervention costly. In underground sites, confined galleries and limited clearances slow down every task. The logistics of reaching the damaged area can take longer than the repair itself.

What really happens on site

Every mine relies on movement. Moving ore to the mill, moving equipment to the line, moving parts to keep systems running. Yet many of the tools used for that purpose were designed for open ground, not for the reality of narrow shafts or uneven slopes.

This gap between design and reality leads to logjams. Crews often rely on improvised methods: using forklifts where visibility is poor, or manually hauling loads that should never be handled by hand. These practices raise safety risks and extend downtime. For managers, that translates to more hours lost and higher costs with no added value.

How Movex Innovation changes the equation

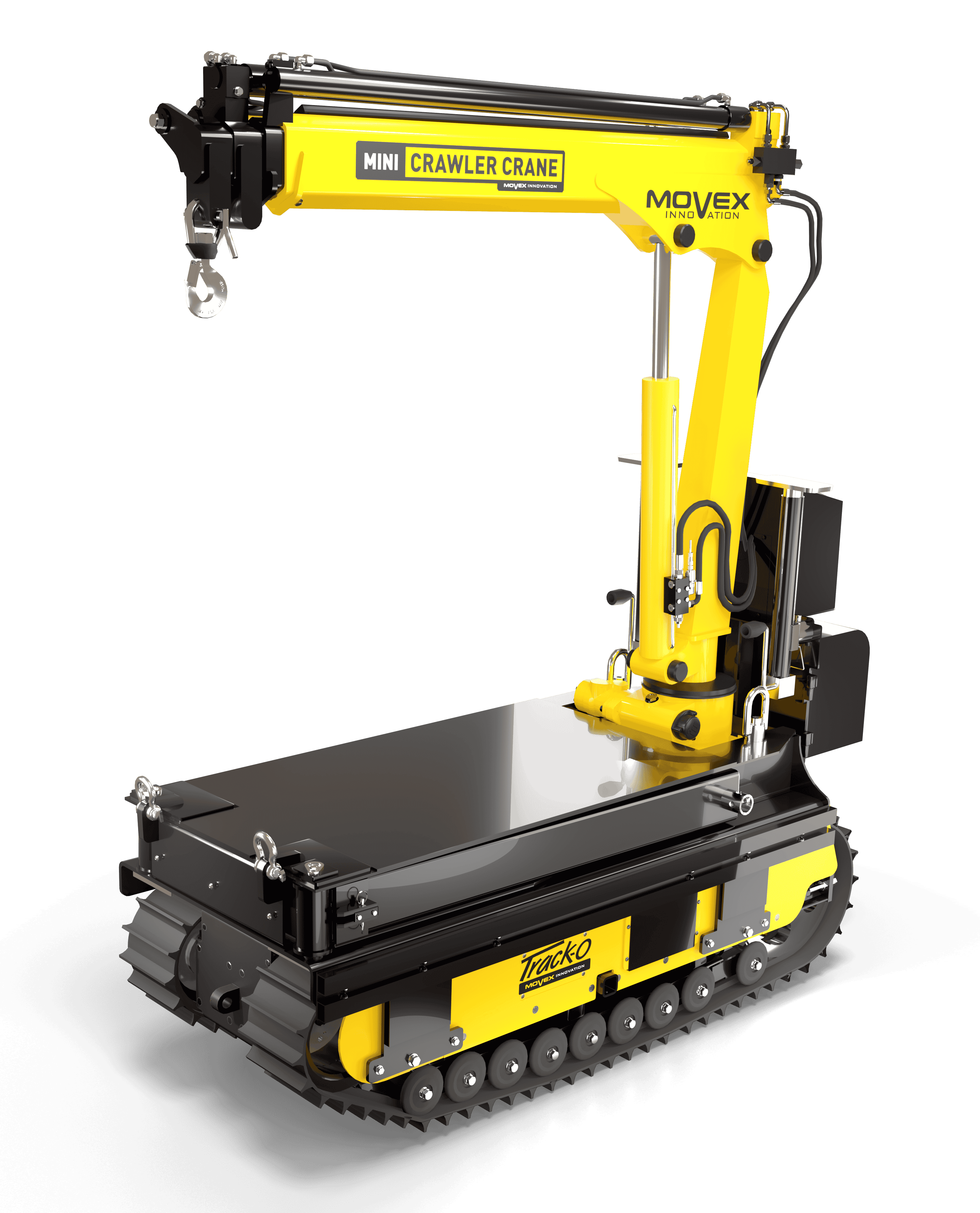

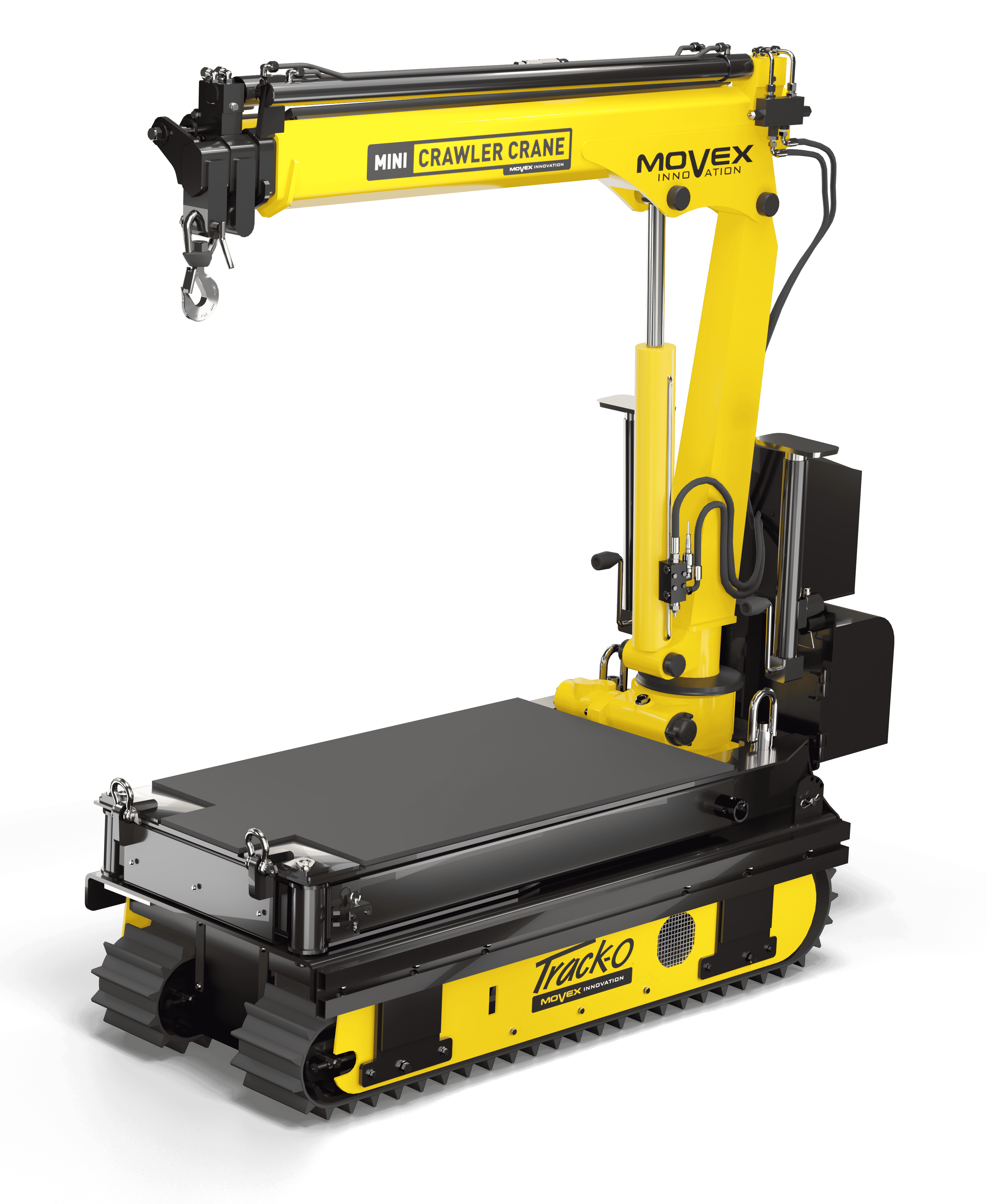

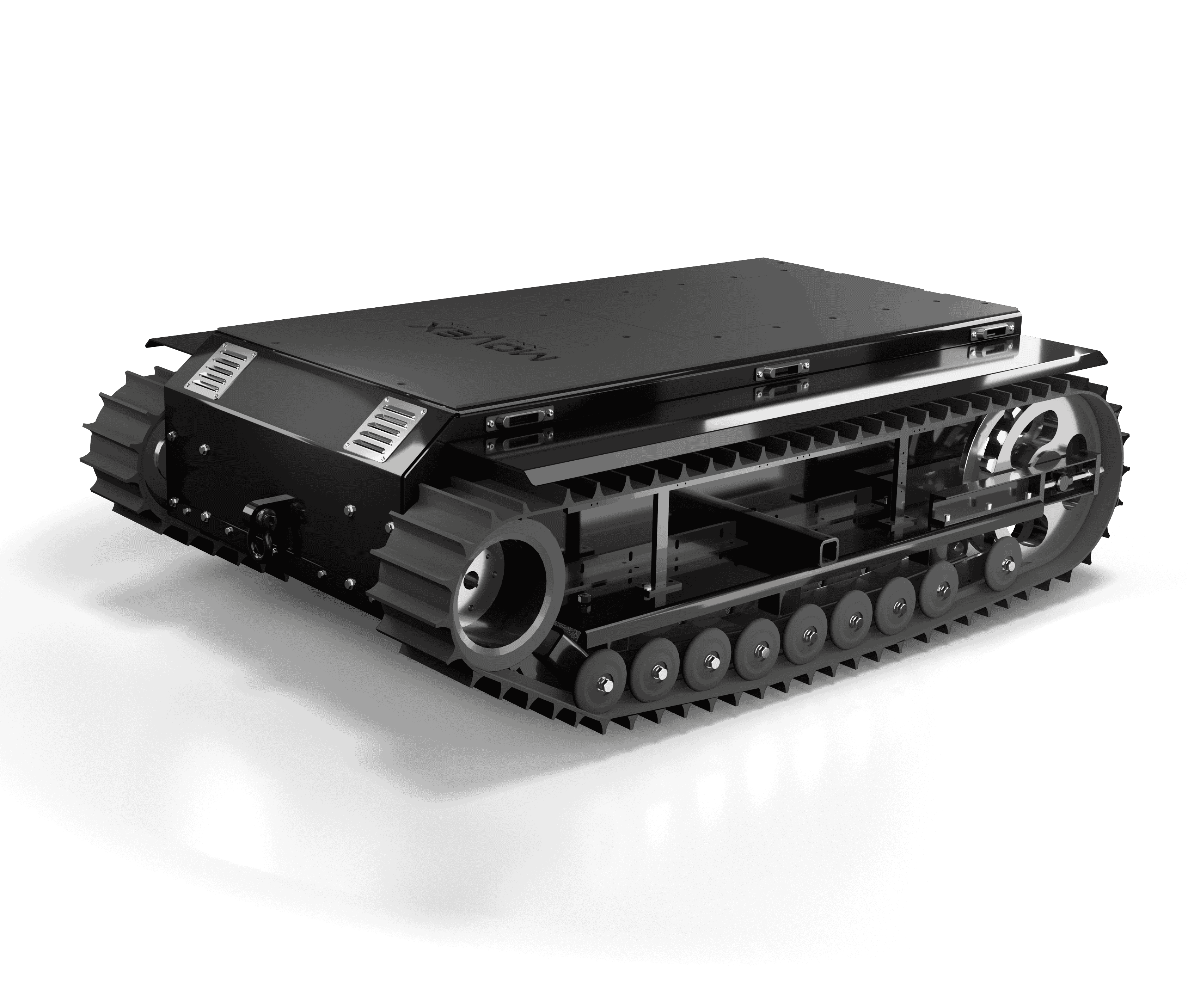

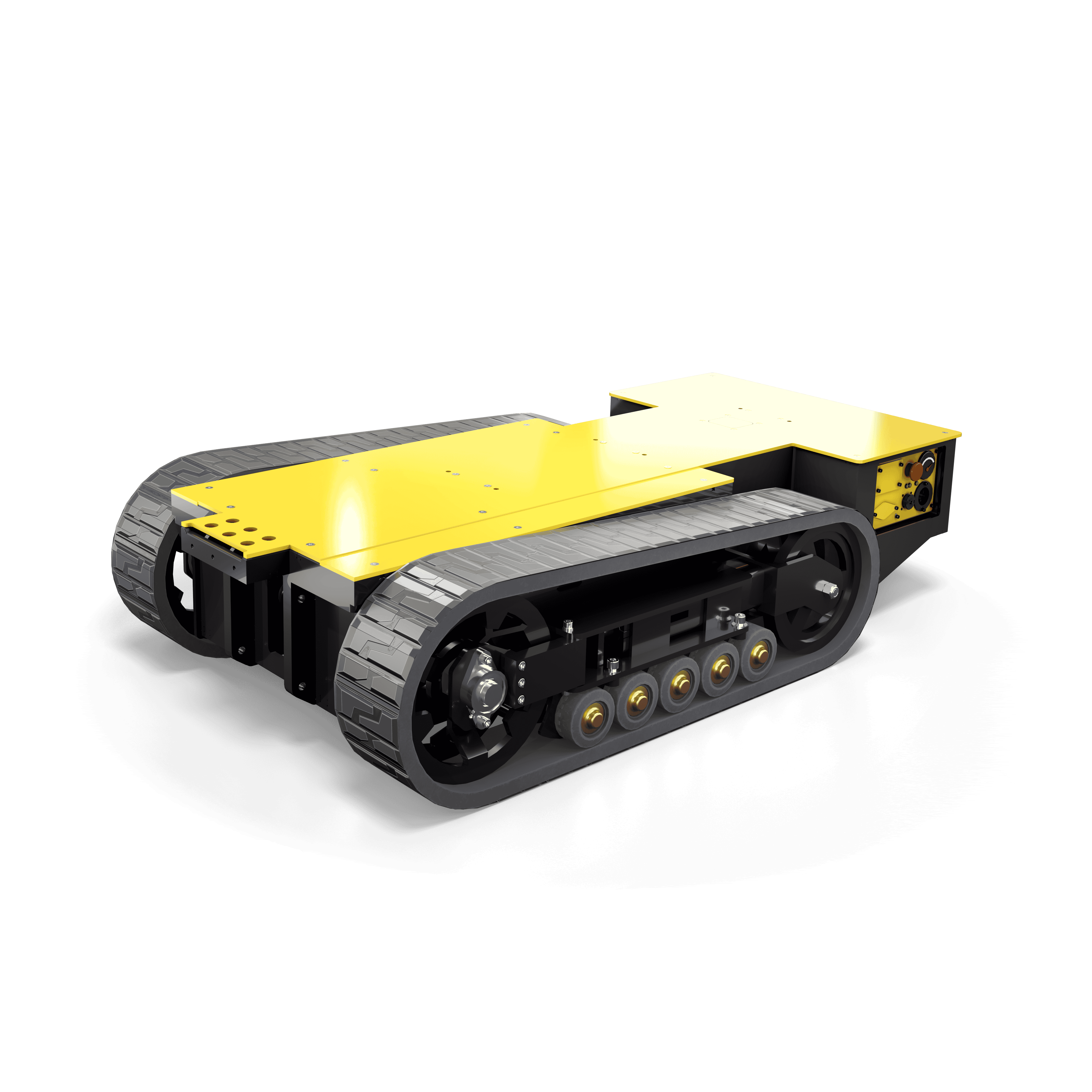

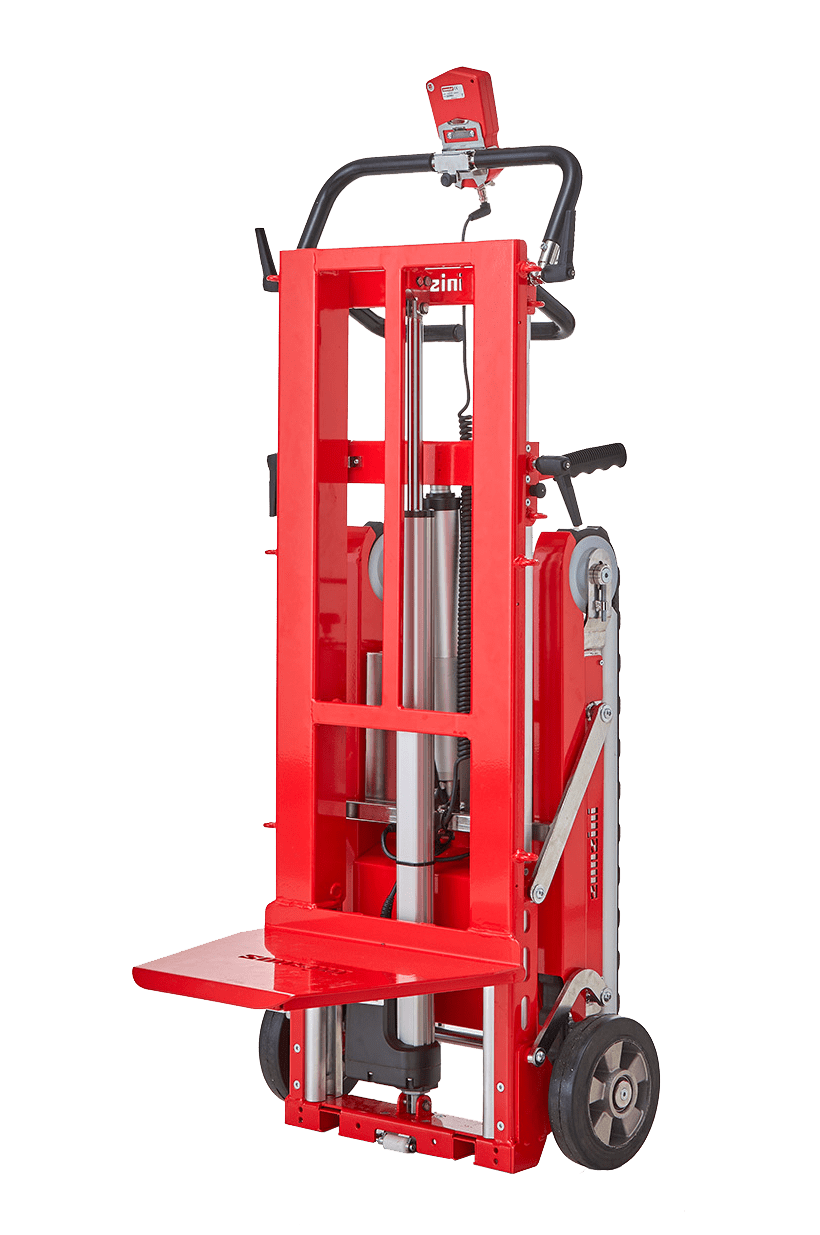

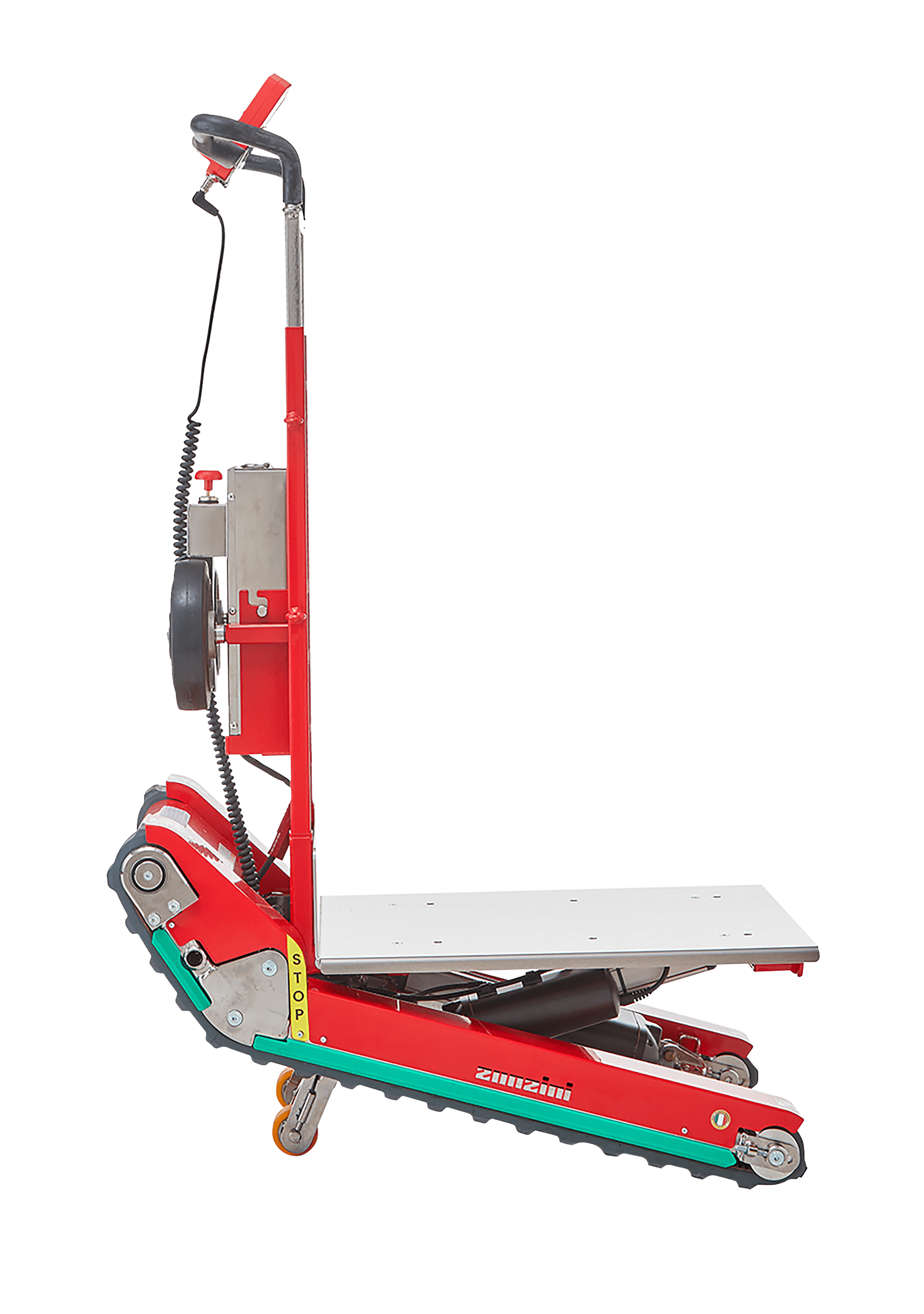

Movex Innovation was created to address this gap directly. We design compact, remote-controlled, electric equipment that transports loads where conventional machinery cannot operate. Whether it’s a conveyor motor deep underground or a pallet of belt rolls on a steep incline, these machines transfer material safely and quickly in the most constrained areas of a mine.

Our heavy-duty material handling equipment for the mining industry combines robustness, precision, and control. Operators can haul up to several tons with minimal effort while maintaining full visibility of the path ahead. The ability to operate them at a safe distance keeps workers out of hazardous zones and reduces exposure to heat, dust, and vibration. Each model is engineered for stability on uneven ground, meaning movement continues even in conditions that would stop traditional machinery.

Reducing downtime and improving safety

When a conveyor stops, response time is everything. Movex Innovation’s mini loaders and mini dozers allow maintenance teams to reach problem areas faster and carry the necessary components in one trip. That speed reduces downtime and restores production sooner.

The safety benefits are equally tangible. Manual handling of massive components is a leading cause of injuries in mining maintenance. Remote-controlled equipment eliminates the need for physical lifting and reduces the risk of falls or crush incidents in narrow passages. For managers, fewer incidents mean lower insurance costs, fewer delays, and higher workforce morale.

Energy efficiency and cost control

Mining operations are under pressure to reduce emissions and improve energy efficiency. Movex equipment contributes to both goals. Each machine is 100 percent electric, powered by high-performance batteries that perform reliably in cold, humid, or dusty conditions. Compared to diesel-driven vehicles, the reduction in noise, fumes, and heat improves working conditions and reduces ventilation needs in underground sites.

From a cost perspective, electric systems also cut fuel expenses and require less maintenance. There are fewer parts to replace, no oil changes, and no complex transmissions to service. Over time, those factors translate into measurable savings and more predictable budgeting.

Real results in the field

At a nickel mine in northern Ontario, a critical conveyor breakdown halted production for nearly a week. The damaged section was located up a narrow incline with a 20-degree grade, requiring the transport of 1,500-lb rollers to complete the repair. Forklifts couldn’t access the area, and manual handling was out of the question.

The maintenance superintendent contacted Movex Innovation, and we quickly deployed an ultra-compact stair climber from our rental fleet. With its remote-controlled operation and compact footprint, the crew transported all replacement components in a single shift—allowing the repair to be completed two days ahead of schedule.

Consider the impact: a conveyor typically moves 400–500 tons of ore per hour. Every hour of downtime represents significant lost revenue.

Impressed by the performance, the mine purchased a unit for ongoing operations. Today, it’s part of their standard maintenance fleet, helping reduce mean time to repair (MTTR) and keeping production moving.

Renting versus owning

Every mine faces different realities. Exploration sites operate on shorter cycles and may need equipment for only a few weeks each year. Established extraction sites, by contrast, have permanent maintenance teams working year-round. Movex supports both models with flexible access options.

Renting material handling equipment makes sense when mobility needs fluctuate. It provides access to specialized equipment without tying up capital or storage space. Mines can deploy next-generation material handling equipment during shutdowns, belt replacements, or expansion phases, then return them when the work is complete. The rental fleet is maintained by Movex Innovation’s technicians, ensuring that every unit arrives ready for the job.

For long-term sites, ownership often proves more economical. Having dedicated equipment available on-site avoids scheduling conflicts and supports preventive maintenance programs. Mines that own their machines can customize configurations to specific layouts, integrate them into existing logistics systems, and train workers for continuous use. Movex Innovation assists with both acquisition and training, ensuring that each investment delivers long-term value.

Looking forward

Mining is entering a period of accelerated modernization. Automation, electrification, and environmental performance are driving every decision underground and at surface sites. Material handling may seem secondary compared to extraction or processing, yet it defines the rhythm of production. When movement stops, everything downstream stalls.

Movex Innovation focuses on keeping that movement steady: through equipment designed for the realities of mining, not for ideal conditions. Whether rented for a shutdown or purchased for long-term use, these mini loaders and mini dozers keep mining processes streamlined, workers safe, and throughput on track. In an industry where every hour counts, that reliability makes all the difference.

Reduce your downtime—talk to a mining equipment specialist today.

Read Our Latest Articles