Electric Hand Truck: Tackling Load Transport in Elevator-Free Worksites

Written by William Nicholls | June 17th 2025

Picture two very different worksite transport scenarios. Above ground, a stadium expansion is in full swing, and teams must lug heavy cement bags and steel beams up and down multiple levels—except the freight elevator isn’t operational yet.

Or how about this? Below ground, deep in a mine, the only route for moving conveyor rollers and motors is a steep, narrow shaft with no proper lift. Despite their distinct settings, both locations share a universal challenge: how to transport heavy loads quickly and safely when elevators are unavailable or out of service.

In these examples, traditional equipment like forklifts or pallet jacks often won’t fit or can’t navigate cramped corners and staircases. Manual labor becomes the fallback solution, but it brings excessive strain, inefficiency, and huge safety risks.

Thankfully, a new generation of electric hand trucks—often referred to as safe stair climbers—has arrived to tackle these problems head-on, transforming the way teams move essential goods in both above-ground and underground material handling operations.

Throughout this article, we’ll explore the key hurdles faced by industries lacking functional elevator systems and highlight specific sectors that benefit from powered stair climbers for lifting heavy equipment up stairs.

Challenges of lifting heavy equipment up stairs and worksite transport

Underground and above-ground worksites that lack functioning elevators make things complicated for workers.

For one thing, the loads themselves can be enormous, sometimes exceeding the capacity of standard elevators or escalators. When an elevator is out of order or an escalator cannot handle the weight, transporting critical equipment—motors, winches, wires, or even entire mechanical assemblies—becomes a project in itself. Staff end up relying on alternative routes, like narrow stairs or temporary ramps, which quickly complicate their work.

This brings us to another fundamental problem: limited access and tight spaces. Underground tunnels, ventilation shafts, and service corridors are rarely designed with heavy worksite transport hauling in mind. High ceilings and generous turning radii are luxuries that subterranean environments simply don’t have.

Bends in the corridor might be too sharp for a traditional forklift, or the floors might be uneven, adding yet another obstacle to an already difficult task. Even in above-ground sites—think of a sprawling facility with multiple levels—using a conventional pallet jack on steep ramps is not an easy feat.

Physical safety risks also multiply when workers must rely on manual carrying methods. Whether they are lugging heavy toolboxes or large HVAC units, the strain on backs, shoulders, and knees is significant. This raises the likelihood of workplace injuries and accidents. In confined underground spaces, where visibility is low and the air may already be compromised by dust or fumes, one slip on a staircase can lead to serious harm.

What’s more, from a regulatory standpoint, many jurisdictions impose weight limits on manual handling, requiring managers to seek mechanical solutions that meet strict safety and environmental standards.

In a nutshell, stairs are often the final, unavoidable barrier to getting a job done. A long flight leading to a service tunnel or a steep staircase descending to a platform can slow down even the most straightforward tasks. Legacy lifting methods like pulleys or basic winches can be awkward, time-consuming, and sometimes unsafe when used in cramped settings. Many sites also lack the structural reinforcement to anchor such systems securely.

Compounding all of these problems with lifting heavy equipment up stairs are equipment limitations and energy costs. Standard forklifts, loaders, or cranes usually need ample space and sturdy ground support—conditions frequently absent underground.

Fuel-powered machines can create ventilation hazards in enclosed areas, while battery-powered equipment may require frequent recharging if not designed for robust performance. If recharging is not convenient or the machines themselves are not maneuverable enough, productivity dips quickly.

There is a better way for lifting heavy equipment up stairs.

Industries that benefit from electric hand trucks

Many industries face the same dilemma: moving large or heavy materials in places where conventional worksite transport options are limited. Below are several key sectors where electric stair climbers make the greatest impact.

Mining

Mines are an obvious example of challenging, confined spaces. Worker safety remains a top priority. The combination of steep inclines, unstable ground, and restricted movement increases the risk of accidents, making reliable material handling solutions extremely important.

Workers in mines must transport heavy loads such as conveyor rollers, replacement motors, and large bearings to keep the mine’s infrastructure operational. The underground environment presents unique logistical hurdles: narrow tunnels, damp and uneven floors, and low ceilings can make navigation nearly impossible for most conventional machinery. In addition, shafts leading to lower levels often don’t include passenger or freight elevators—or those elevators may only handle modest loads, limiting their usefulness for moving equipment.

Here, an electric stair climber makes an immediate impact. Instead of ferrying conveyor components or ventilation systems by hand, workers use a stair-climbing vehicle designed to handle heavy loads in tight spaces such as catwalks, mechanical rooms, and walkways. This specialized equipment is particularly useful for transporting materials like conveyor rollers across long distances, including bridges and elevated walkways, where traditional lifting methods are impractical.

Productivity rises as fewer team members are needed to move the same load, and safety improves thanks to powered lifting. This technology streamlines tasks such as replacing conveyor belt rollers, shifting motors in small mechanical rooms, and conducting maintenance work inside ore processing plants—operations that can span as much as a mile. By reducing manual handling and improving efficiency, stair-climbing equipment plays a critical role in keeping mining installations running smoothly while minimizing downtime.

Construction et renovation

Large-scale construction and renovation projects often require moving masses of materials like cement bags, steel beams, scaffolding, and drywall.

When freight elevators are unavailable or out of service, teams resort to physically carrying loads up and down stairwells. This not only slows the job but risks worker fatigue and injury.

An electric hand truck or a safe stair climber, like the Mini-Dumper, can mitigate these issues by allowing a single operator (or a small team) to guide heavy items with minimal physical strain. This same type of equipment can be used for waste transport, removing debris or demolished materials from a site quickly—an essential step in keeping the worksite orderly and secure.

Utilities and infrastructure

Maintenance crews for gas, water, or electricity utilities routinely service underground stations, such as pump rooms or power distribution chambers. These environments can be cramped and damp, with multiple flights of stairs that connect different underground levels, such as the basements found in hydroelectric dams. Employees may need to bring in transformers, pumps, and other bulky components that can easily exceed safe manual carrying limits.

A powered stair climber is a great advantage. With models like the TT-66, teams can load bulky items, stabilize them on the stair climber, and navigate steps with relative ease. This lessens the risk of dropping expensive or delicate equipment, and it spares workers from intense physical exertion. The technology also shines when moving heavy batteries or breaker switches in industrial settings, where reliability and balance are critical.

Railway and subway maintenance

In the context of subways or commuter rail systems, speed and throughput are paramount. Repairs often need to happen overnight or during limited service windows. Workers might have to carry generators, track-repair tools, and other heavy apparatus down multiple flights of stairs. If the station’s escalators or elevators are out of service, that leaves only one option: carrying everything themselves.

With a powered stair climber or Mini-Dumper, carrying loads to the platform becomes more manageable. Maintenance crews can also use specialized equipment to extract waste, rubble, or old materials from renovation sites deep beneath city streets.

For example, the TT-47 or a stair climbing crane can navigate narrow corridors and tight corners to deliver or remove parts near railway tracks. The machine’s compact design means it can pass through standard doors and operate in confined station areas.

Industrial and building services

Above-ground buildings are not immune to the hassles of transporting heavy items without an elevator. Certain older or specialized facilities might have mechanical rooms in basements or sub-basements, accessible only by stairs. HVAC units, fuel tanks, or telecommunication equipment often weigh hundreds—if not thousands—of pounds and are impossible to maneuver with a simple pallet jack.

Electric stair climbers are invaluable for these scenarios. They reduce or eliminate the need to set up cranes outside the building or tear down walls to accommodate oversized equipment. The device can also be used for roof access, where bringing up mechanical systems via internal stairs is less disruptive than scheduling a crane to hoist equipment over the edge of a building.

Product spotlight: Versatile powered stair climbers for every load

Not all electric hand trucks are created equal. Each worksite and material handling application has different needs. Fortunately, several of Movex Innovation’s specialized products address a range of weight capacities and operational constraints:

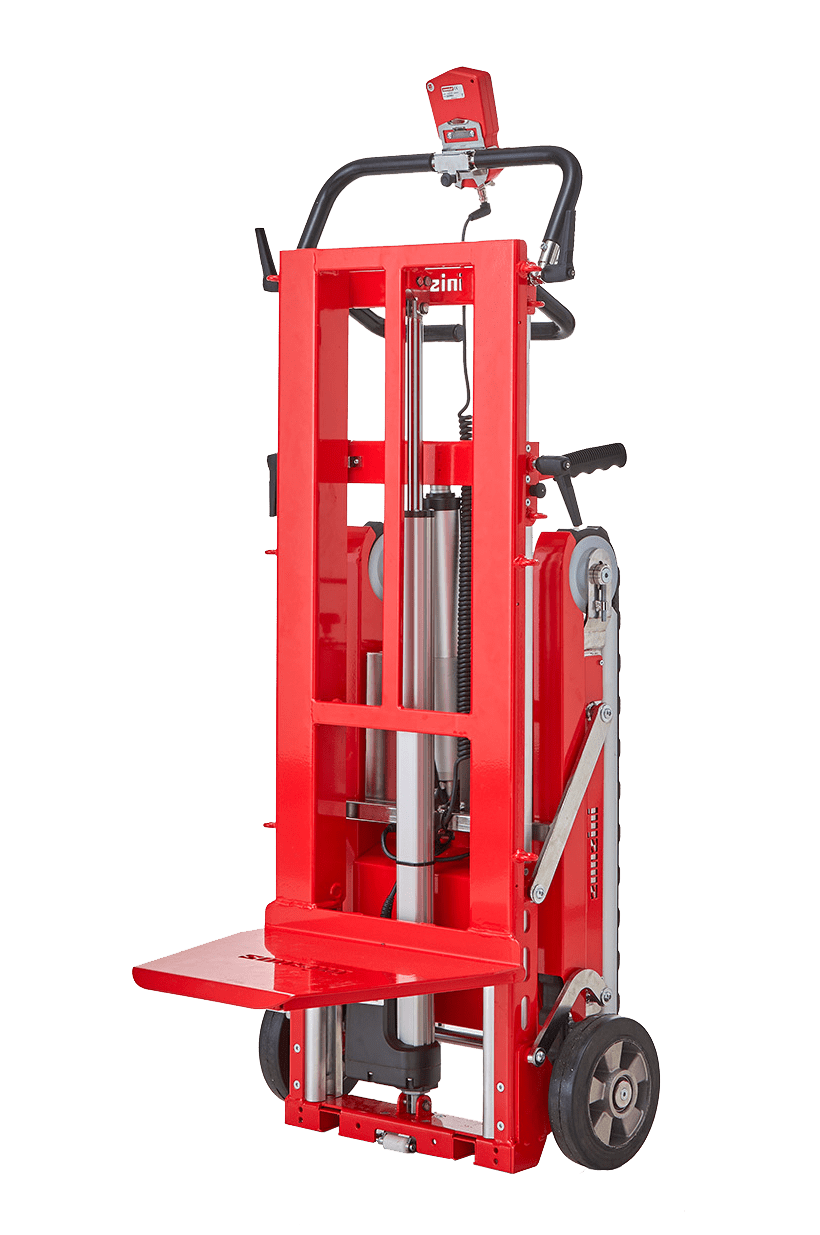

- TT-47 powered stair climber: Ideal for moderate to heavy loads that need stable stair navigation. Its robust framework and balanced center of gravity make it a go-to choice for many maintenance and renovation tasks.

- TT-66 stair crawler: Engineered for truly hefty cargo like transformers, large batteries, or industrial-grade motors. This model’s power and secure grip on stairs allow operators to move exceptionally heavy items without risking mishaps or worker injuries.

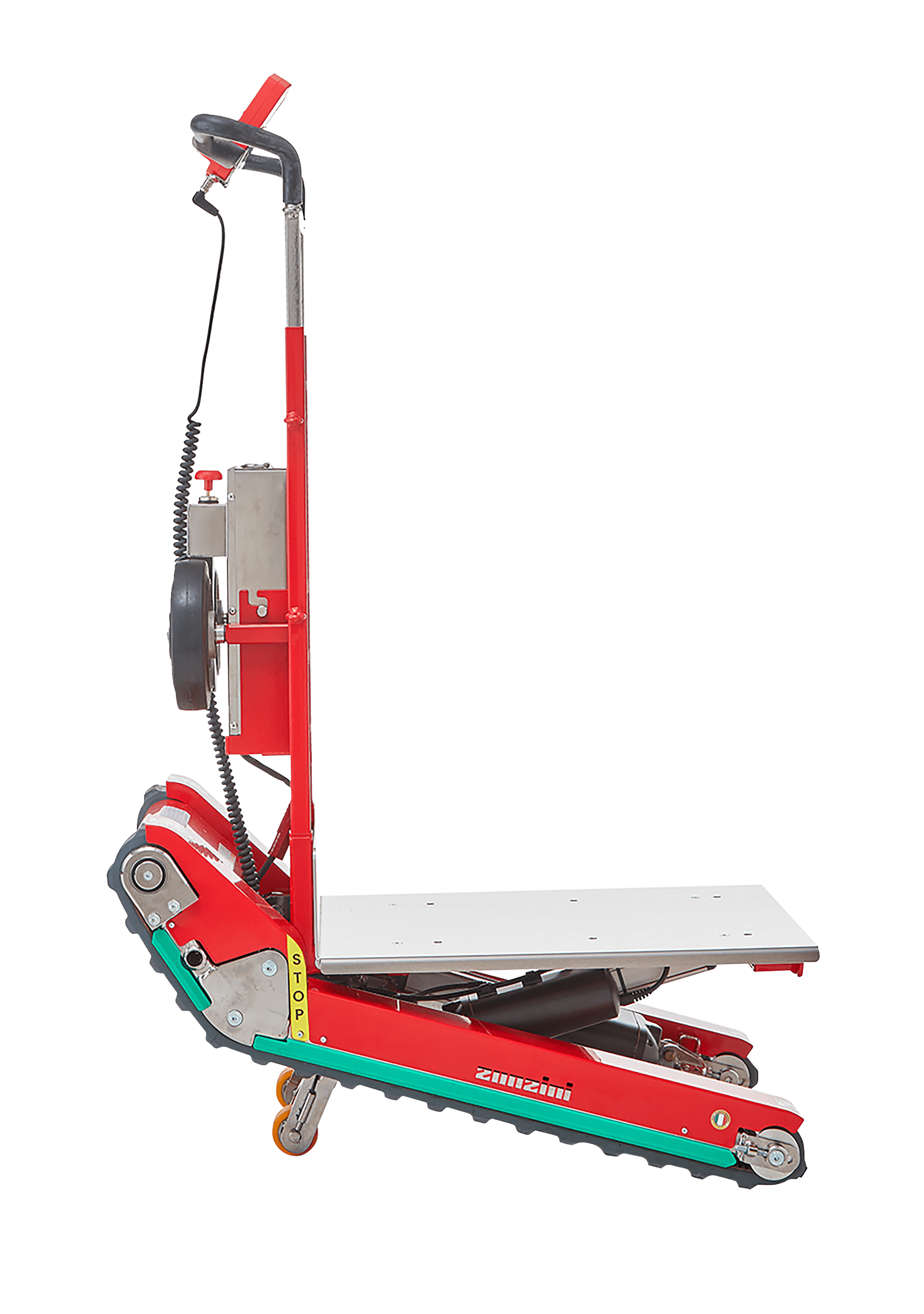

- Mini-Dumper: Perfect for transporting waste, debris, or loose materials such as gravel or concrete scraps. By combining a lifting unit with specialized containers—like an asphalt skip or a concrete skip—the Mini-Dumper becomes a versatile partner for both demolition and construction sites.

- TT-270 stair climbing crane: When load dimensions require a bit more mechanical muscle or reach, this crane-like solution can lift materials that exceed the capabilities of standard stair climbers. It’s particularly beneficial in railway or industrial projects where large machinery must be relocated through tight stairways.

- Zonzini stair climbers (for lighter loads): While heavy loads attract the most attention, many worksites also grapple with smaller but still cumbersome items that need to go up and down stairs. Zonzini stair climbers are ergonomic and user-friendly solutions for mid-range weights.

Ultimately, electric hand trucks are changing worksite transport. Rather than relying on back-breaking labor or makeshift rigs, teams can turn to powered stair climbers that handle steep inclines, tight corners, and hefty loads with ease.

As a result, projects stay on schedule, workers stay safer, and heavy equipment finally has a smooth ride—no matter where the job needs to go.

It's time for you to explore how electric hand trucks can become breakthrough solutions for worksite transport.

READ OUR LATEST ARTICLES