Restoring history beneath Montreal:

The Square-Victoria Subway Station Project

Written by William Nicholls | July 8th 2025

In 2013, the experienced construction firm QMD faced a unique challenge: renovating Montreal’s historic Square-Victoria subway station, a vital transportation hub since the 1960s.

The project was not simple; it required extensive demolition and the rebuilding of concrete and ceramic walls and floors deep underground, with nearly 220 tons of heavy debris needing to be cleared from the site. Adding to the complexity: there were no elevators available, meaning all waste had to be transported manually up two flights, totalling 150 steps.

Underground realities and logistical barriers

The logistics of this project were truly daunting. Initial evaluations revealed significant obstacles with typical debris removal methods. Conveyors were quickly ruled out due to practical limitations; for example, small concrete blocks would roll unpredictably on the conveyor belts, causing jams and operational disruptions. What’s more, the extensive time required for assembling and disassembling conveyors made this method impractical.

The alternative—manual labor—was equally problematic. Hauling the debris manually using two small containers, each capable of carrying only 9 kg, presented serious safety concerns.

The sheer volume of debris meant that up to ten crew members would need to constantly climb stairs, risking injury and exhaustion. High labor costs, worker fatigue, and increased accident risk made manual removal an unacceptable solution.

Clearly, traditional approaches wouldn’t cut it for this demanding and high-risk project.

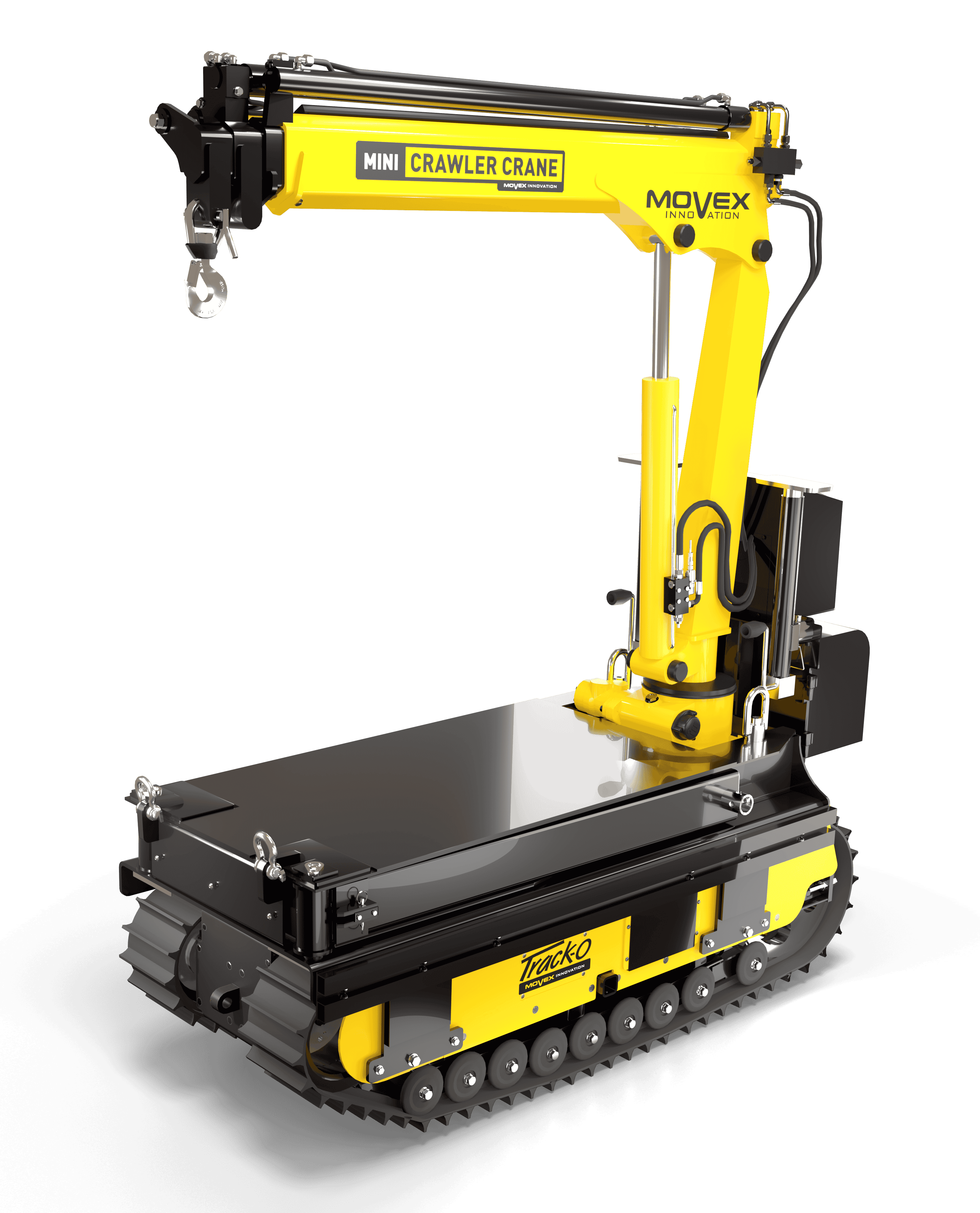

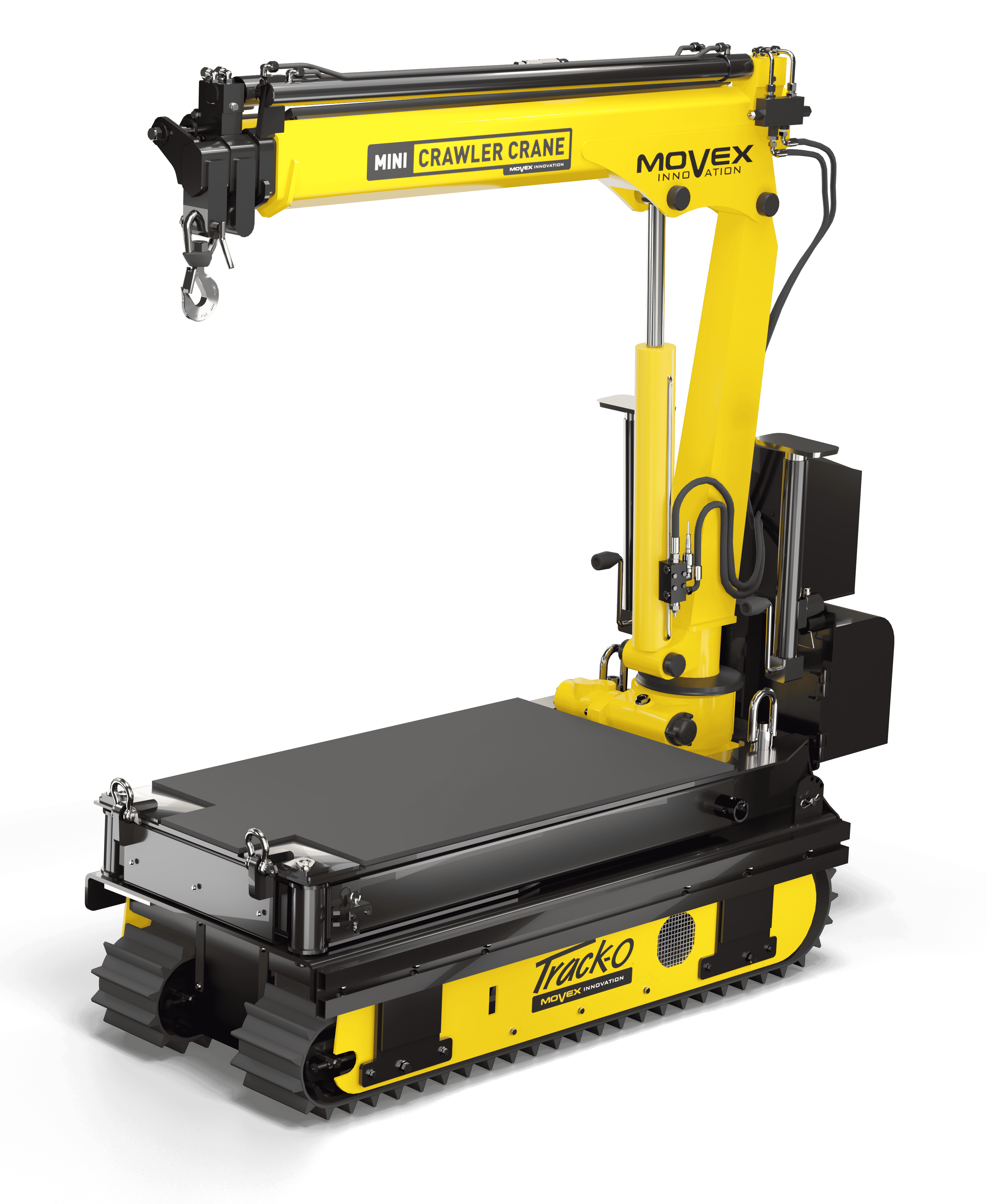

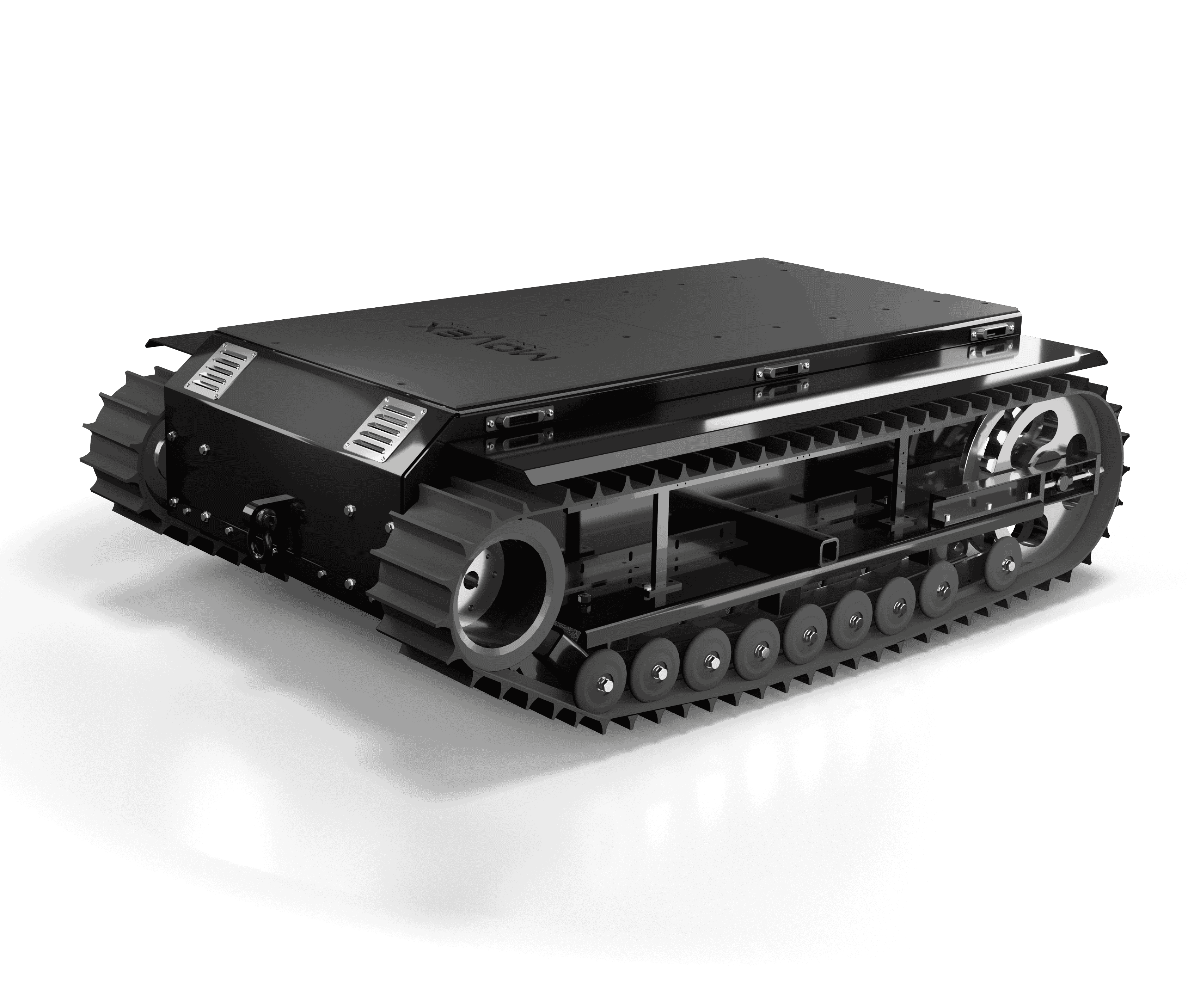

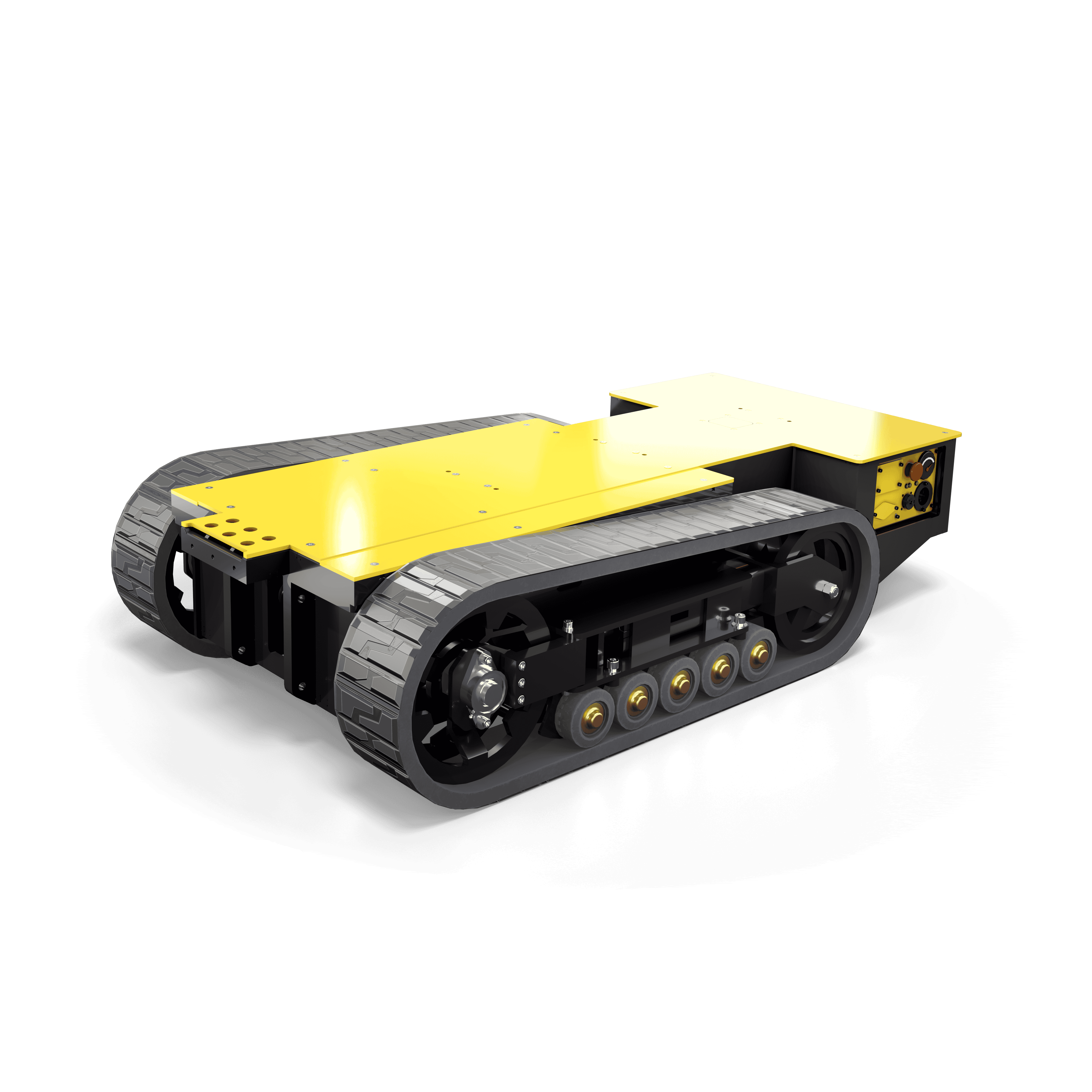

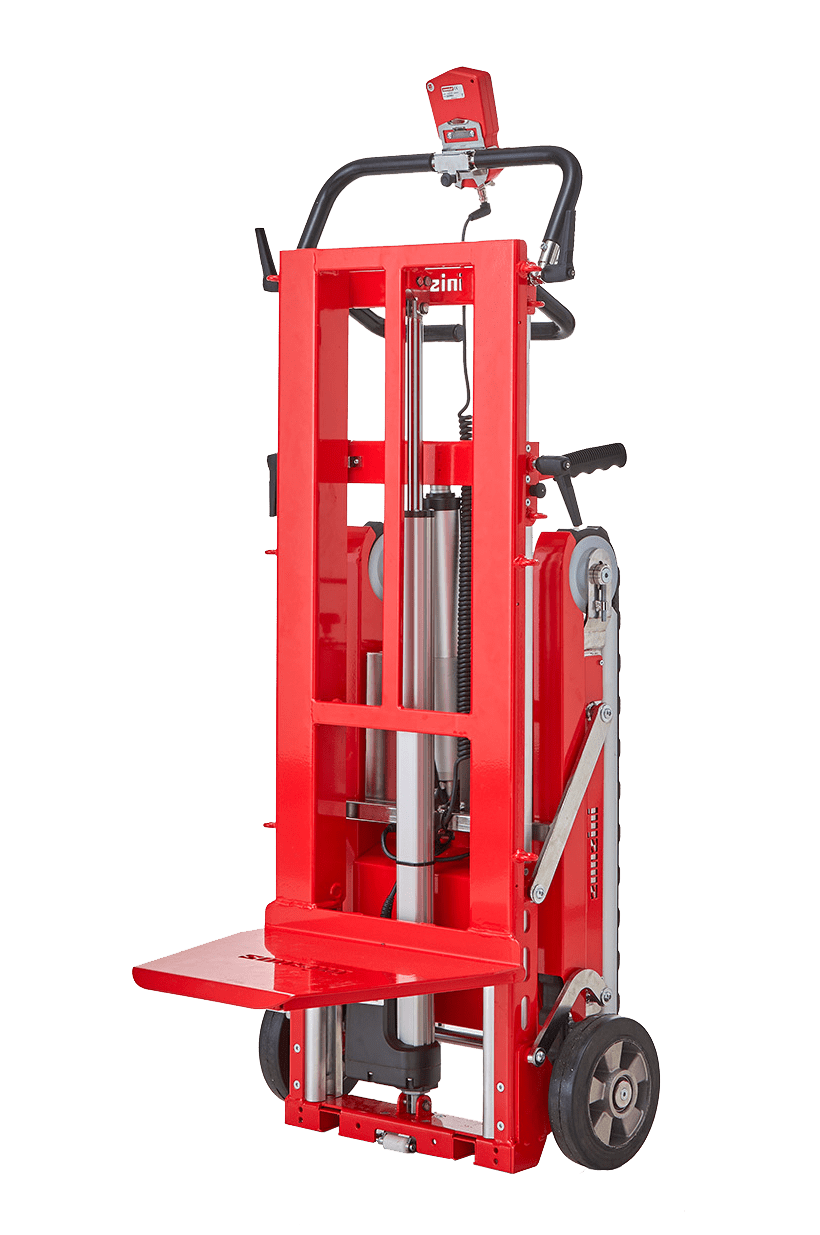

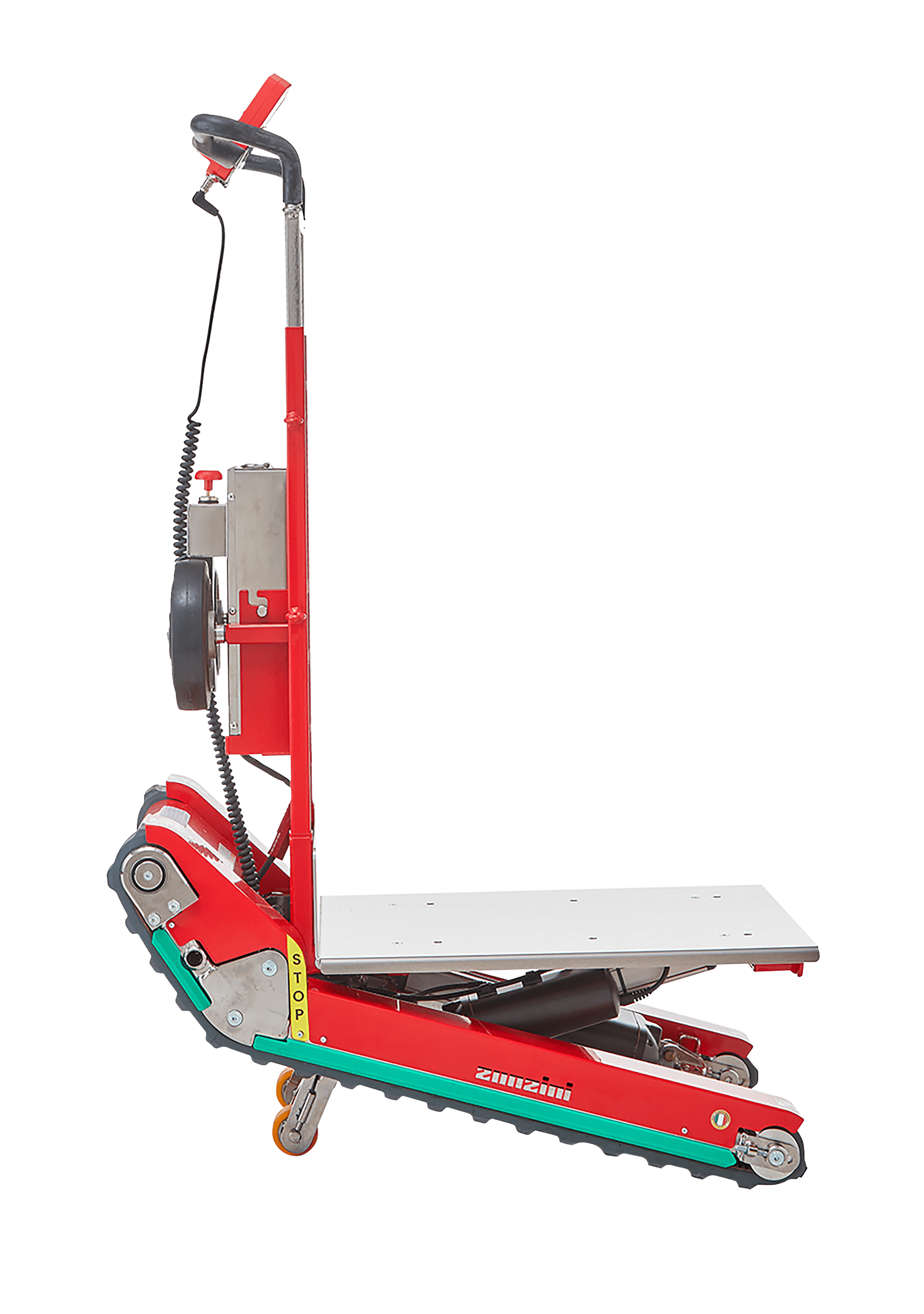

Discovering the Mini-Dumper advantage

To overcome these hurdles, QMD selected an innovative solution: the Mini-Dumper handling system from Movex Innovation. Designed specifically to manage heavy loads in tight indoor spaces and staircases, the Mini-Dumper offered precisely what the project team needed: safe, efficient, and consistent transport of materials.

Throughout the 45-day project, the Mini-Dumper and its two specialized removable hoppers handled a total of 955 loads—around 22 loads each day—with each load weighing between 230 and 275 kilograms.

The debris was carried swiftly up the stairs and deposited into waiting concrete containers positioned conveniently at street level. In total, 19 large containers were filled with approximately 220 tons of construction waste.

Recognizing the intensive demands of the project, the project team equipped the Mini-Dumper with multiple battery packs and charging stations for a trouble-free and optimized operation for up to 14 hours daily.

Practical benefits and real-world results

The introduction of the Mini-Dumper o dramatically simplified the entire project. Instead of a large team struggling with heavy lifting, just two operators managed the entire debris removal process. This not only cut labor costs substantially but also allowed QMD’s skilled workers to focus their energies on higher-value tasks rather than manual handling.

The Mini-Dumper wasn’t just versatile. It quickly became indispensable. After effortlessly removing heavy debris, the stair climbing dumper smoothly transitioned to bringing fresh materials, such as ceramics and cement, into the depths of the station, keeping the renovation on track without missing a beat. Despite daily demands and tough working conditions, the system never faltered, proving its reliability day after day.

The Mini-Dumper also dramatically improved worker safety. By removing the need for strenuous manual labor on steep stairs, workers avoided physical strain and potential accidents altogether, ensuring that everyone finished each day safe and sound.

In sum, Movex’s Mini-Dumper made a truly tough job exceptionally manageable.

A blueprint for future success

The Square-Victoria subway station renovation is an inspiring example of how thoughtful planning, paired with the right tools, can make even the toughest jobs straightforward and safe. It shows that overcoming logistical challenges doesn’t require complicated solutions; often, it simply requires a smarter approach.

By turning high-stakes problems into clear solutions, QMD’s experience demonstrates the lasting impact of choosing the right material handling equipment for grueling jobs.

Tackling a complex job in a confined space?

Discover how the Mini-Dumper can make your next renovation safer, faster, and more efficient.

READ OUR LATEST CASE STUDIES AND NEWS