Rent or buy heavy equipment: What really makes sense for your operation

Written by William Nicholls | November 19th 2025

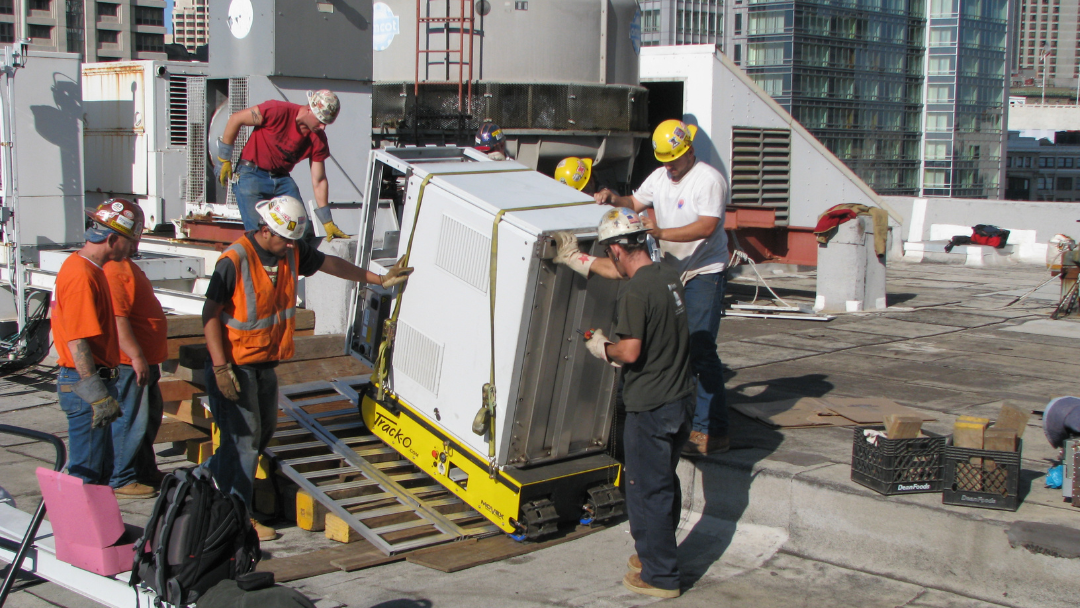

Every project manager faces this question at some point. You’ve got a contract to deliver, a deadline to respect, and a crew counting on you to make the right call. The job is demanding, the terrain unpredictable, and the margins often thinner than they should be.

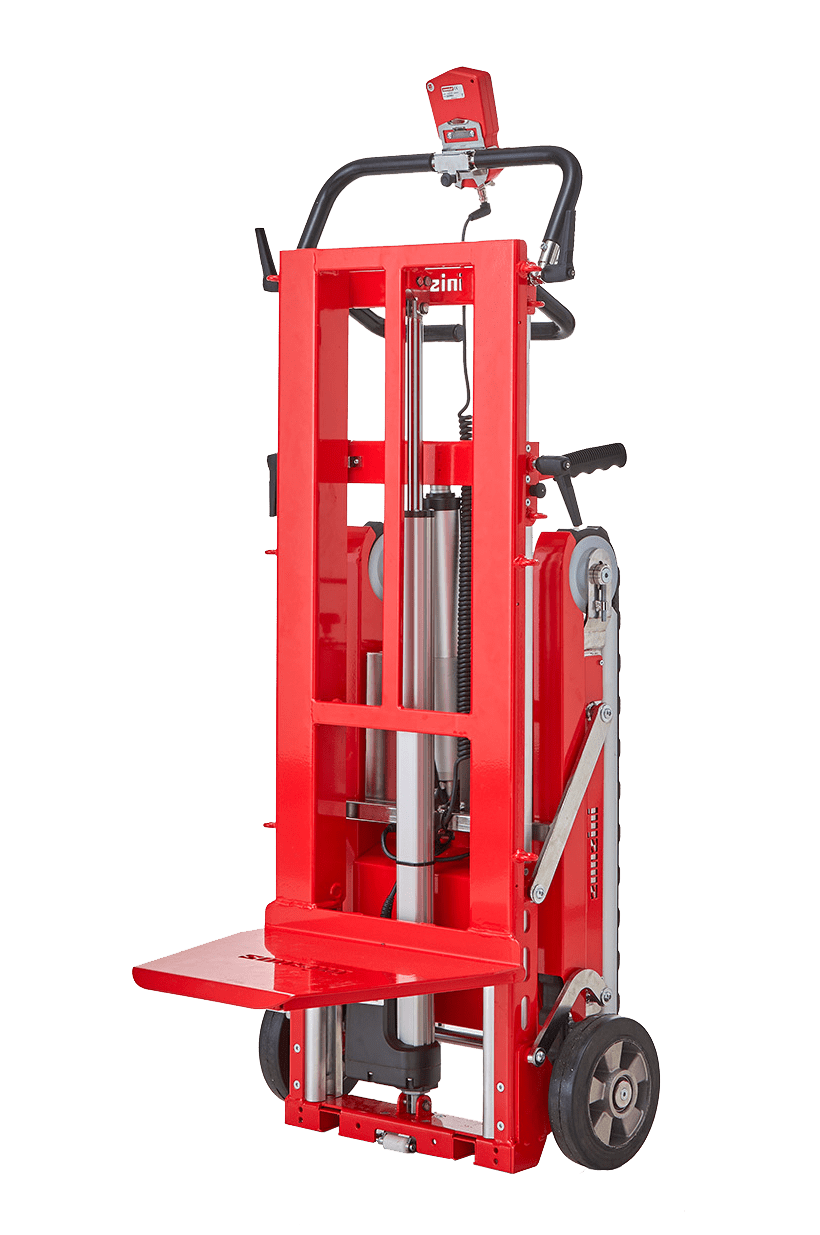

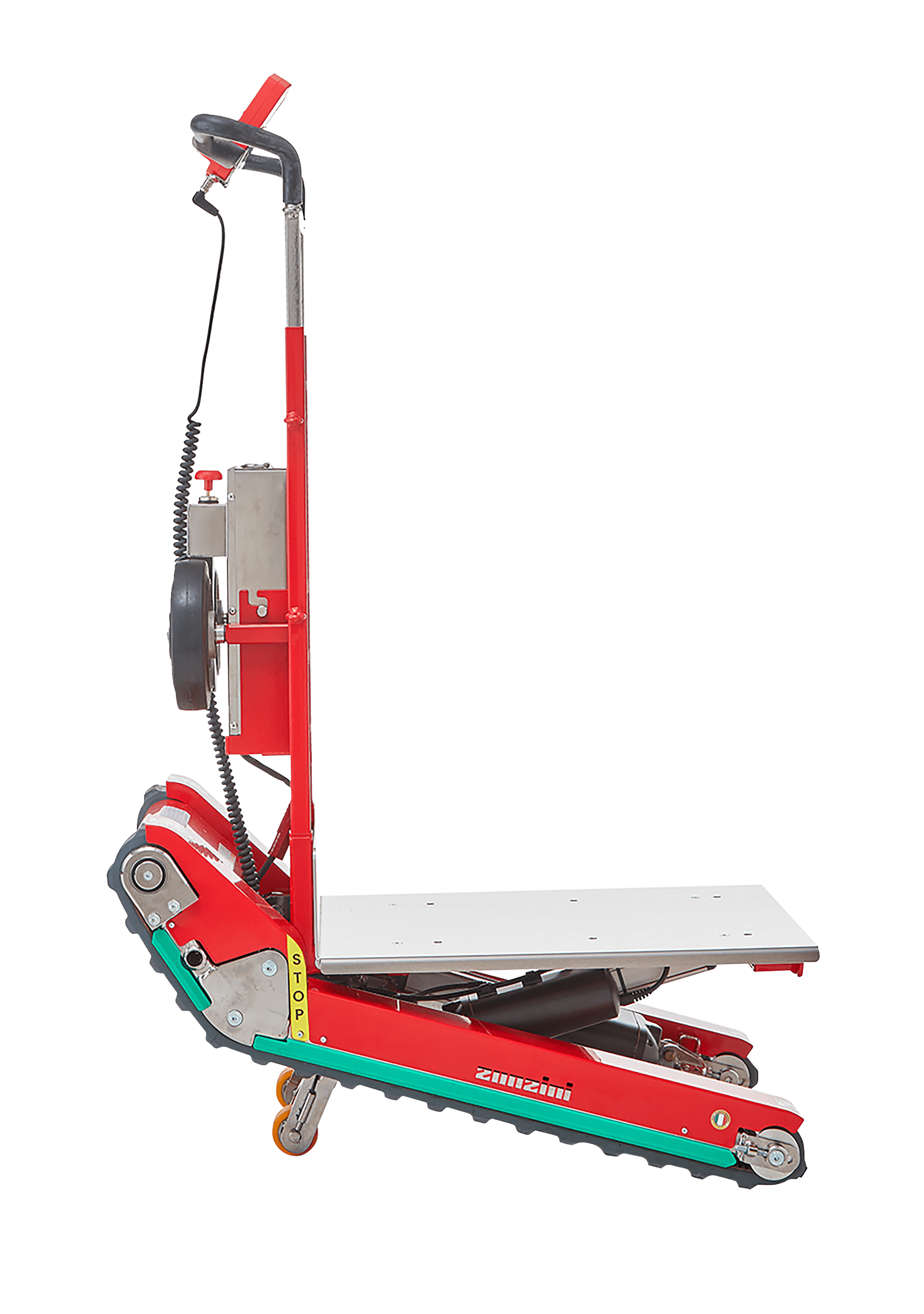

The material handling equipment you choose is more than a tool. It’s the backbone in every lift, haul, and move. So when the next project rolls in, how do you decide whether it’s better to rent or buy heavy equipment?

It is rarely a simple choice. The answer depends on how you work, how often you use your machines, how fast your projects turn around, and how much control you want over reliability and costs. The real decision is equal parts financial and strategic. And for many companies, it defines how efficiently they grow.

When renting keeps you ahead of the game

Imagine you are managing a job with tight timelines and a workload that suddenly doubles. You need an extra piece of heavy equipment on site by the end of the week. You do not have time to wait for approvals or financing. Renting lets you move immediately. One call, one delivery, and the machine arrives on time, inspected, maintained, and ready to perform. The project keeps moving. The team keeps working. The schedule stays on track.

That is the primary and most evident advantage of renting: flexibility. When you rent, you adapt to your workload rather than making your workload conform to your ownership. You can increase your material handling equipment when demand spikes, then scale back when it slows down. There are no long-term obligations, no monthly loan payments looming over you, and no idle machinery occupying space in a warehouse.

For small and mid-sized businesses, that agility can be a lifesaver. It allows you to take on new types of work or short-term contracts without overstretching your budget. Renting is also a great way to access specialized or next-generation machines that you might not need full-time yet. You can test out a specific model, see how it performs in your conditions, and make a more informed decision before purchasing.

Storage is another hidden cost that renting avoids. Not everyone has the facilities to safely park and maintain heavy machinery year-round. Renting means you can use what you need, when you need it, and return it when the work is done. The supplier handles maintenance, inspections, and transportation. You focus on what you do best: completing the job safely and efficiently.

When buying becomes the smarter play

Now picture a different story. You have several teams working at once. The same type of equipment is required on almost every job. You have rented that machine more times than you can count, and each month the rental invoices keep stacking up. At some point, you realize you could have already owned the machine outright. That is the turning point where ownership becomes the better investment.

Buying gives you control. When you own your heavy equipment, you set the schedule, you handle maintenance on your terms, and you never have to wait for availability. You know your machine’s history, its strengths, and its weak spots. Your operators get to know it as well, which often leads to better performance and fewer mistakes. It becomes part of your daily routine, part of your team.

Owning also gives you financial leverage. Instead of paying for temporary access, you are building long-term value. That equipment becomes a tangible asset on your balance sheet, one that strengthens your borrowing capacity and increases your company’s overall value. Depending on your jurisdiction and accounting strategy, you may also benefit from depreciation or tax deductions that make ownership even more cost-effective over time.

For many companies, ownership is a statement of independence. It means you trust your capacity, your pipeline, and your people enough to invest in your future. When you roll your own machine onto a job site, you know exactly what you are bringing. You are not adjusting to someone else’s maintenance schedule or hoping the rented material handling equipment arrives in good shape. You are in full control of your tools, your time, and your results.

The real cost of material handling downtime

No matter how you plan your heavy-duty equipment strategy, one thing always comes at the highest cost: downtime. A machine that stops mid-project can cause a chain reaction of delays. Crews wait around. Deliveries are delayed. Clients become impatient. Profit diminishes hour by hour. Whether you’re renting or owning, if the machine fails, everyone loses time and money.

That is why reliability should always guide your decision. Renting from a trusted partner ensures you get equipment that is inspected and maintained before every delivery. You can trust that when it arrives, it is ready to perform. If something does go wrong, a good rental supplier can provide immediate replacements or on-site assistance to get you moving again.

Ownership, on the other hand, puts that responsibility squarely on you. It means developing a maintenance schedule that prevents breakdowns and ensures the longevity of the system. It means having technicians or trusted service providers who can react quickly when issues arise. This may sound demanding, but it also gives you full visibility into the health and performance of your heavy equipment. When properly managed, owned jobsite equipment can serve you for years and even retain resale value at the end of its cycle.

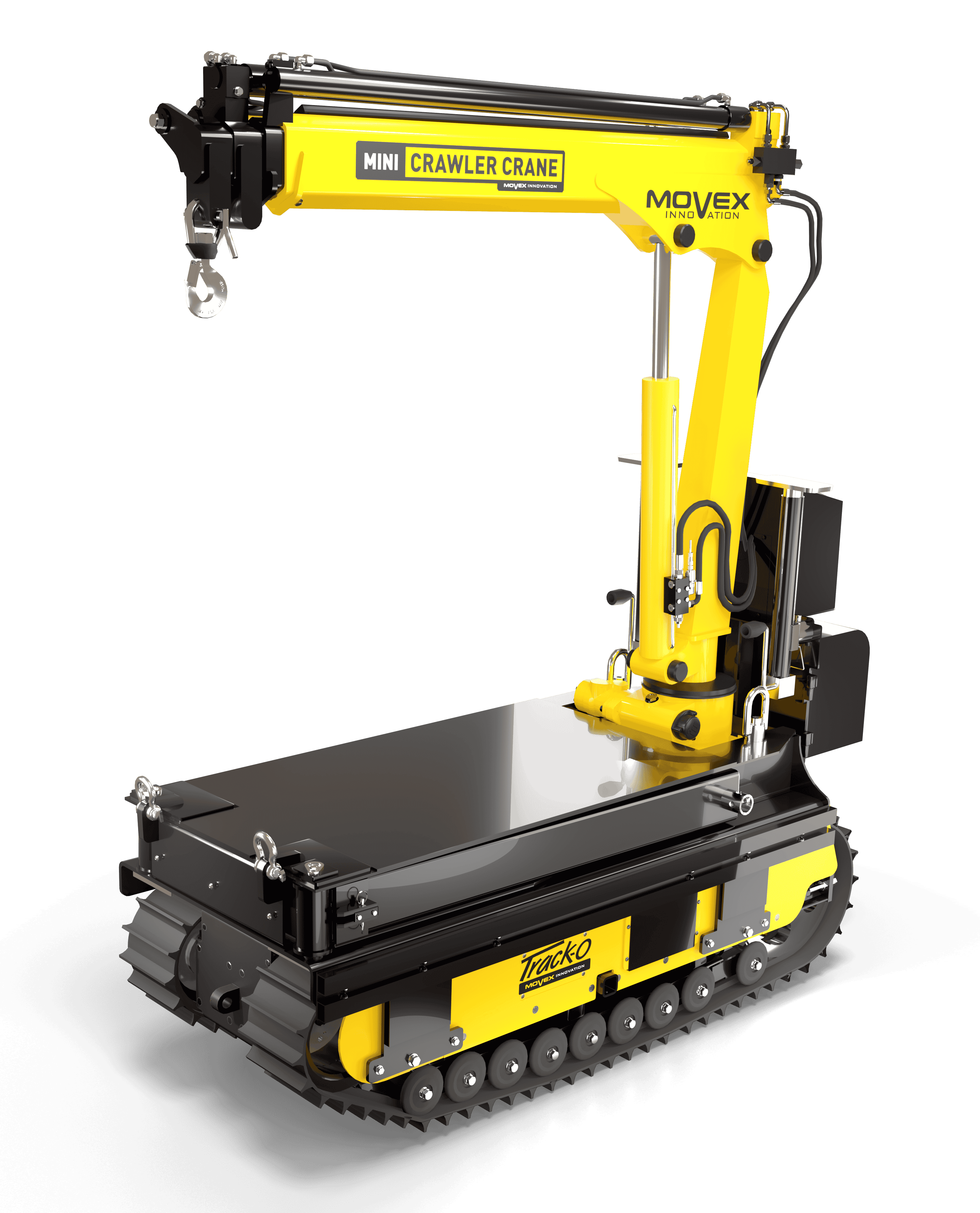

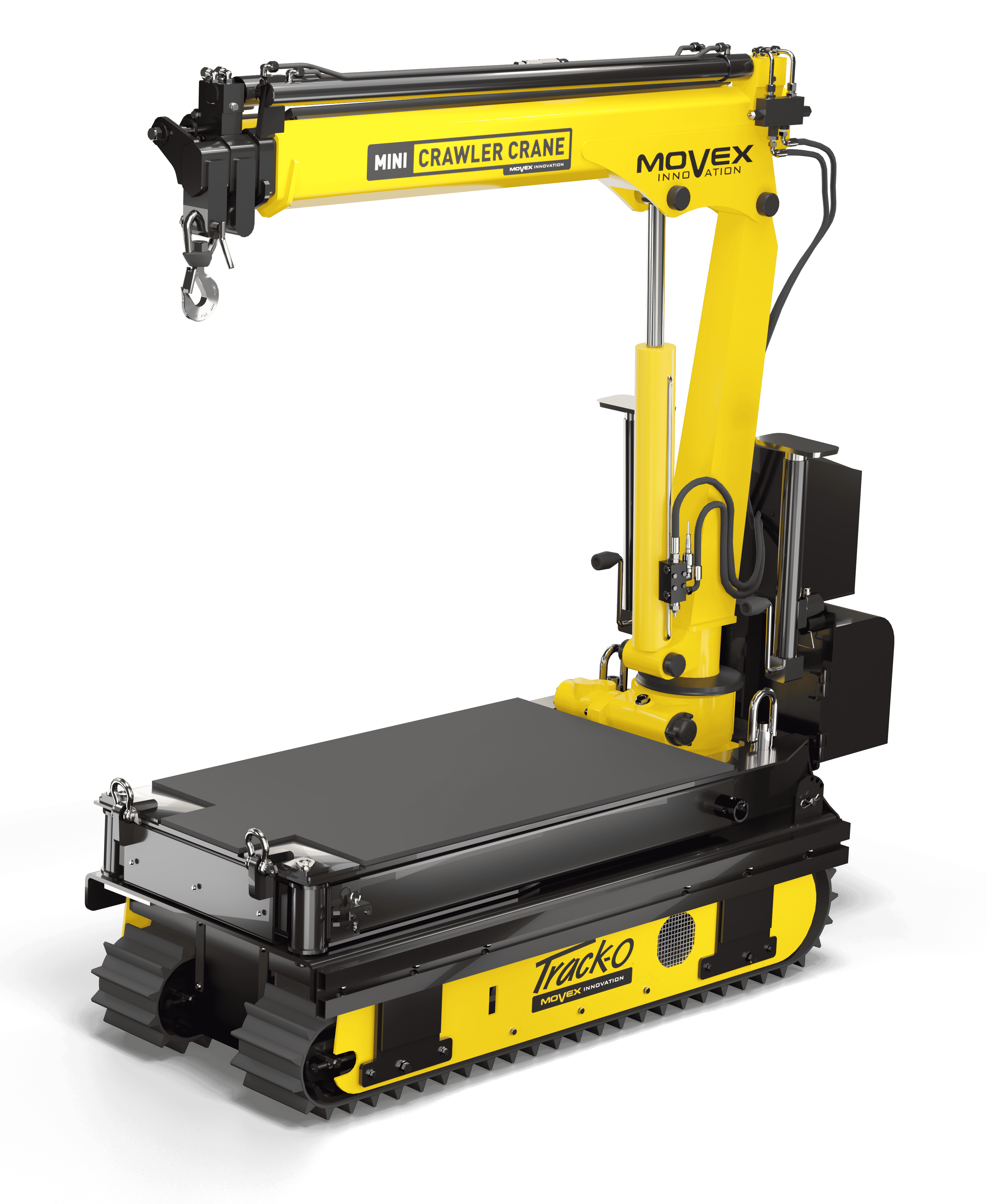

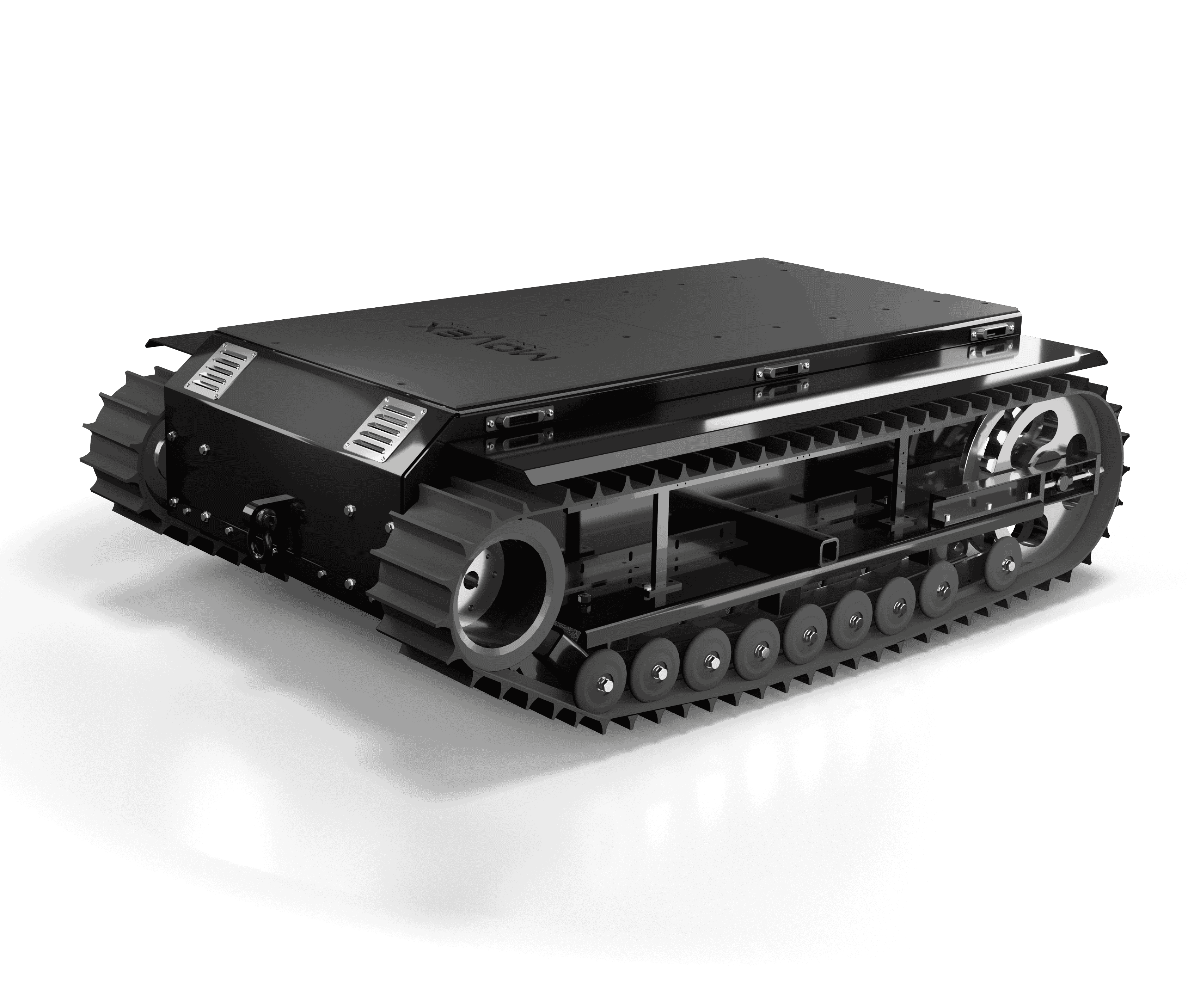

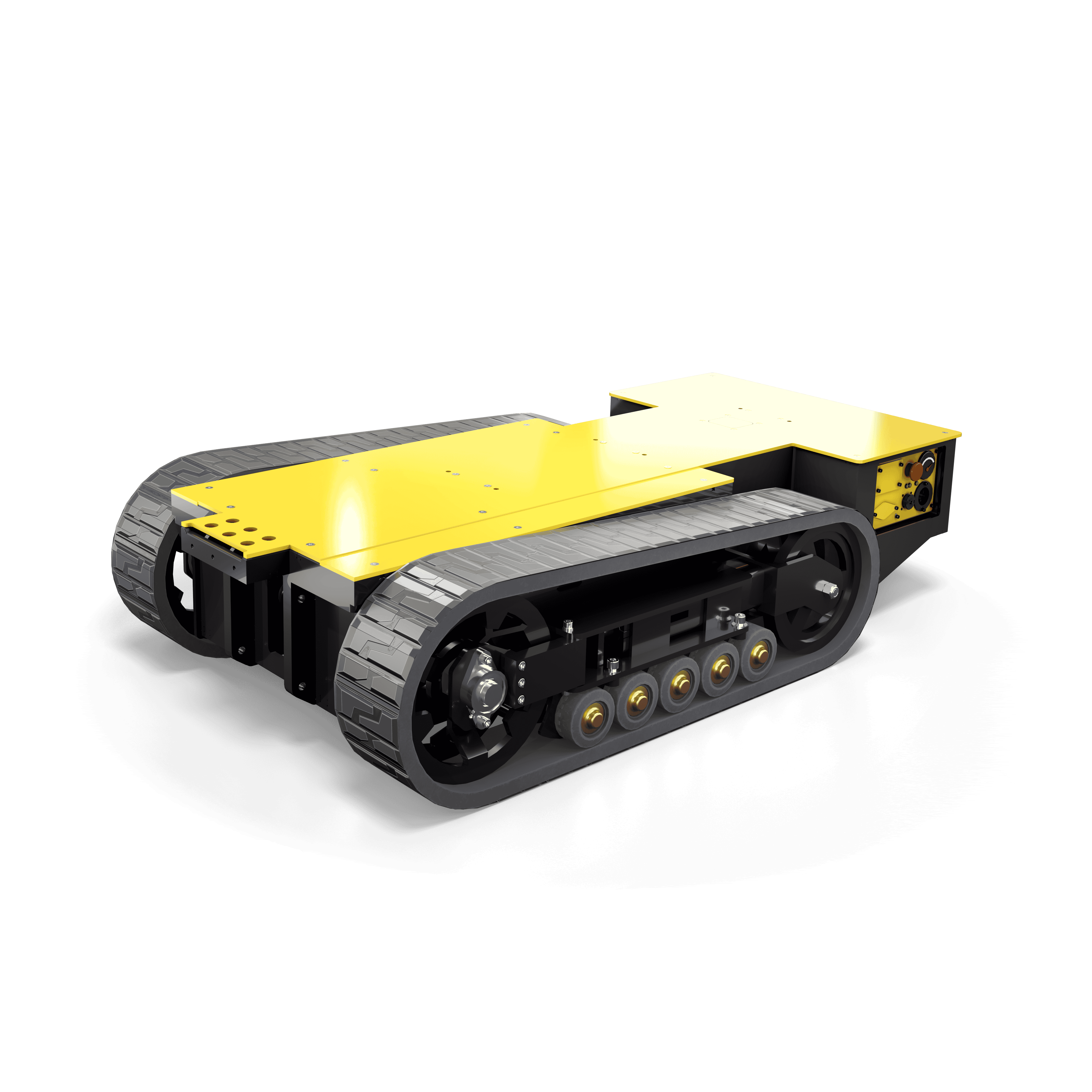

At Movex Innovation, we have seen both sides of the equation. We have witnessed crews immobilized because a machine failed on a Friday afternoon with no backup in sight. We have also seen operators who own and maintain their machines with such precision that they outperform fleets twice their size. It all comes down to preparation, discipline, and choosing the right partner to support you.

Finding the balance between flexibility and control

Most businesses end up somewhere between both worlds. They buy the essential machines they use daily and rent others when project requirements fluctuate. This hybrid model provides the best of both options: control where it matters and flexibility where it counts.

If you handle repetitive jobs in predictable conditions, ownership brings long-term stability and savings. If your projects vary in scope, environment, or duration, renting prevents your capital from being tied up in machines that might sit idle. The key is knowing your workload patterns and calculating how much time each type of material handling equipment spends in action versus waiting in storage.

It also helps to look beyond the price tag. Consider the administrative effort, logistics, and training that come with both models. Renting can simplify operations when you lack manpower for maintenance or storage, while ownership can streamline decision-making once your business grows and your usage stabilizes. Both paths can be profitable when aligned with your reality.

Movex Innovation helps companies find that balance. We analyze usage data, maintenance costs, and safety requirements to identify when renting still makes sense and when ownership becomes inevitable. Sometimes, the right answer is not one or the other, but a gradual shift from rental to purchase as your operations evolve.

What it comes down to

The smartest operators look beyond the short-term cost and think in terms of uptime, predictability, and overall productivity. They understand that a reliable, safe, and well-supported piece of industrial equipment pays for itself in performance long before the numbers settle in a spreadsheet.

Not sure if renting or investing is the right call? We’ll help you do the math, compare your options, and find what fits your workflow best. Let’s make your next decision one that moves your business forward.

Let’s evaluate your project needs together

READ OUR LATEST ARTICLES