Heavy Duty Machines: New Material Handling Solutions for Mining Operations

Written by William Nicholls | August 28th 2025

Mining operations run on tight schedules and even tighter margins. Equipment failures, weather setbacks, and logistical bottlenecks can turn a profitable day into an expensive loss.

That is why mining managers depend on a new generation of heavy-duty machines designed to perform despite the harshest mining conditions. The latest material handling solutions are built for maximum uptime, greater load capacity, and easier maintenance, giving operators the tools they need to keep production moving and meet ambitious targets.

The biggest challenges of the mining industry

Mining operations face more pressure points than ever. Production demands are increasing, regulations are tightening, and the shift toward the electrification of heavy mining equipment is changing how sites are planned and run.

At the same time, workers must work under strict safety requirements, meet environmental responsibilities, and control costs that can spike without warning. These conditions touch every stage of the operation, from extraction to transport to processing.

Worker health and safety

Mining remains one of the most dangerous industries in the world. On-site teams face hazardous environments with risks, such as cave-ins, rock falls, dust inhalation, and equipment accidents.

Safety becomes even harder to maintain in confined tunnels or remote underground locations where emergency response is limited.

Fatigue from long shifts, coupled with exposure to harmful noise, vibration, and diesel fumes, puts both short- and long-term health on the line.

For these very reasons alone, managers are looking for innovative material handling solutions that can tackle the heavy handling to minimize sick or injury leaves and workers’ compensation costs.

Environmental impact and regulations

Mining companies are under increasing stress to reduce greenhouse gas emissions, limit water use, and minimize land disruption. Tailings (the waste byproducts of mining) are one of the biggest environmental issues, requiring careful handling and containment. At the same time, stricter government policies and ESG regulations demand that mines adapt quickly or face penalties, reputational damage, and project delays.

Cost control and operational efficiency

Running a mine is expensive. Equipment maintenance, labour, and fuel are major cost drivers, and energy prices continue to fluctuate. Inefficient processes or unplanned equipment downtime can wipe out profits in a matter of hours. Staying profitable means controlling costs without sacrificing safety or production objectives.

Transition to electrification and decarbonization

The push toward electrification is reshaping the mining industry. Companies are expected to reduce diesel use and integrate electric machines into their fleets. This shift requires building charging infrastructure, ensuring battery performance in extreme heat or cold, and making legacy systems compatible with new electric equipment. Each step demands time, investment, and careful planning.

Talent shortage and workforce aging

Finding and keeping skilled workers is harder than ever. Many seasoned operators are approaching retirement, and fewer young workers are entering the field. On top of that, modern mining relies more on automated and digital equipment, which requires training existing staff members and attracting new hires with different skill sets.

Automation and technology integration

Automation, AI, and remote monitoring can boost productivity and safety, but adoption comes with challenges. Mines face high upfront costs, potential cybersecurity threats, and resistance from teams who are used to traditional ways of working. The transition demands both investment in technology and buy-in from the workforce.

Ore grade decline and resource depletion

As ore quality declines, more material must be moved and processed to extract the same amount of resource. This increases energy use, drives up costs, and generates more waste. The result is added strain on both operations and the planet, forcing companies to innovate just to maintain output.

From traditional heavy duty machines to modern material handling solutions

Ask any veteran in the industry, and they’ll tell you what it was like keeping the old fleet running. Machines guzzled fuel, broke down in the middle of shifts, and demanded constant maintenance just to stay operational. Employees worked around the limitations, knowing downtime could stretch for hours while production targets slipped further away.

Today, the landscape is changing. Mines are turning to modern material handling solutions developed to last longer, run cleaner, and deliver consistent performance. The difference between traditional equipment and newer heavy mining equipment is more than upgrades; it’s about redefining how work gets done in an industry where every minute counts.

| Conventional heavy-duty machines | Contemporary material handling solutions |

| Manual labour and high risk | Automated, remote-controlled equipment |

| Diesel emissions and ventilation needs | Electric material handling solutions with zero emissions |

| Slow, repetitive cleanup | Fast, efficient heavy handling |

| Limited access to confined areas | Compact heavy mining equipment that goes where others can’t |

| High-maintenance and costly downtimes | Reliable, low-maintenance heavy duty machines |

Movex Innovation’s material handling solutions

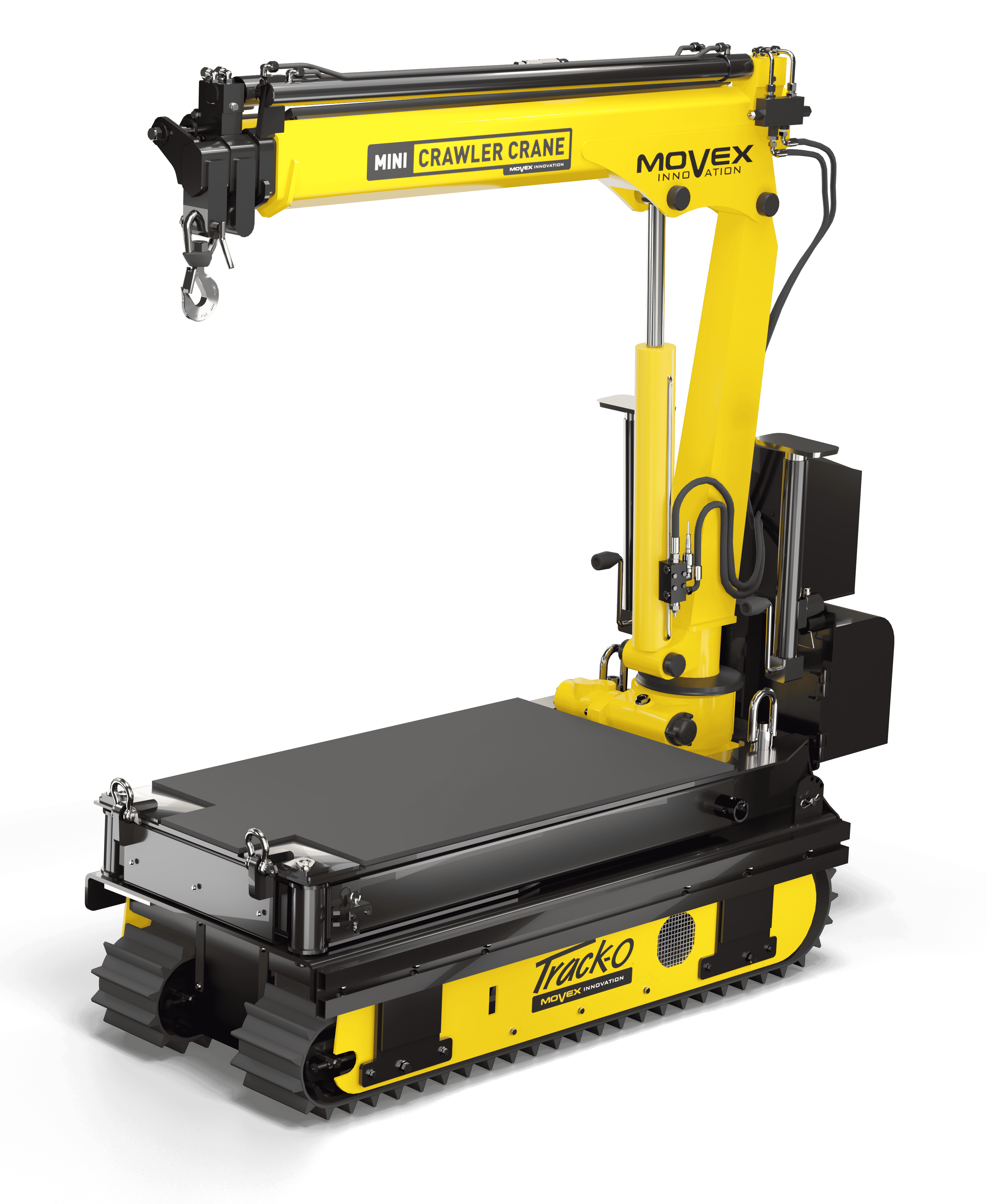

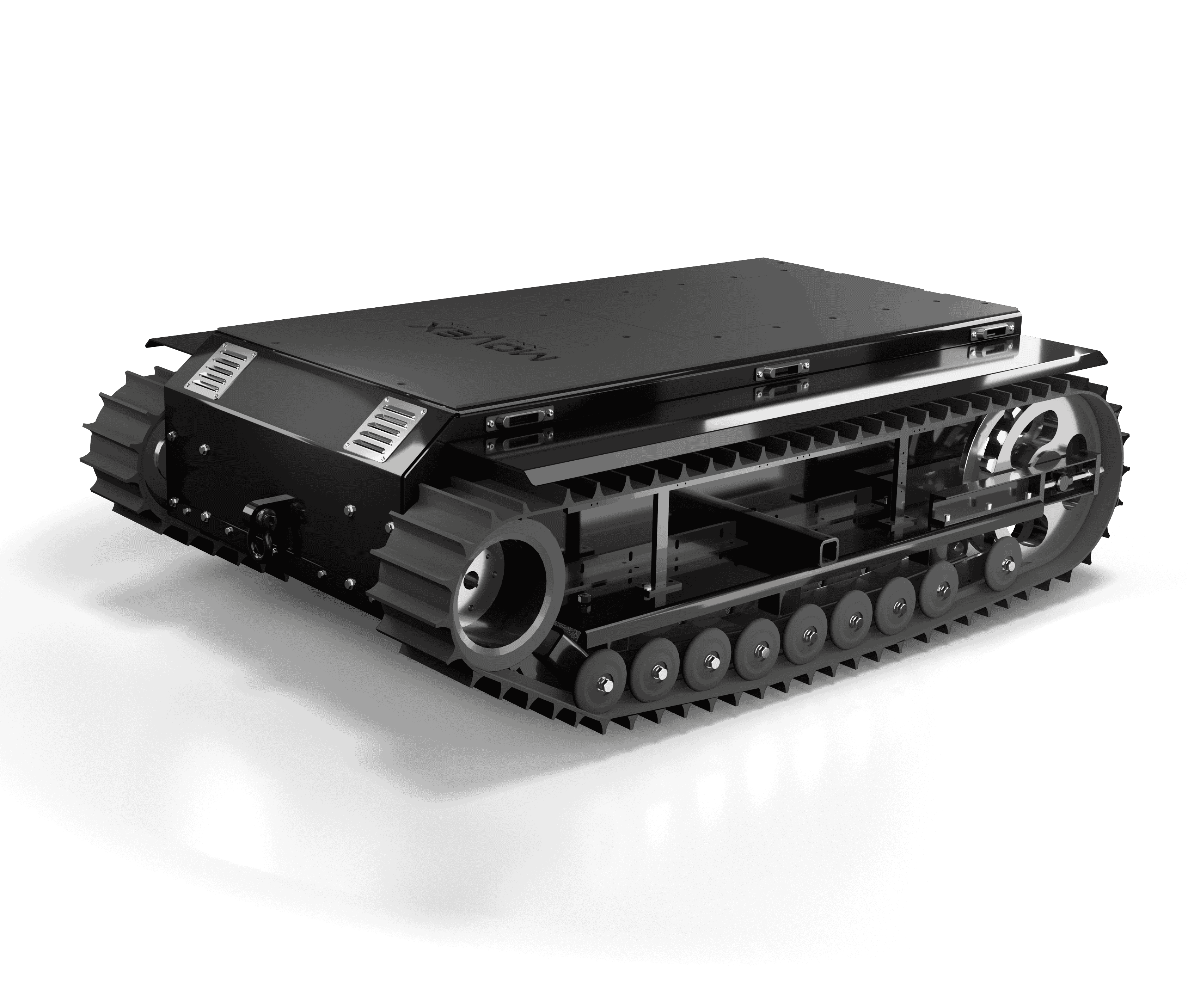

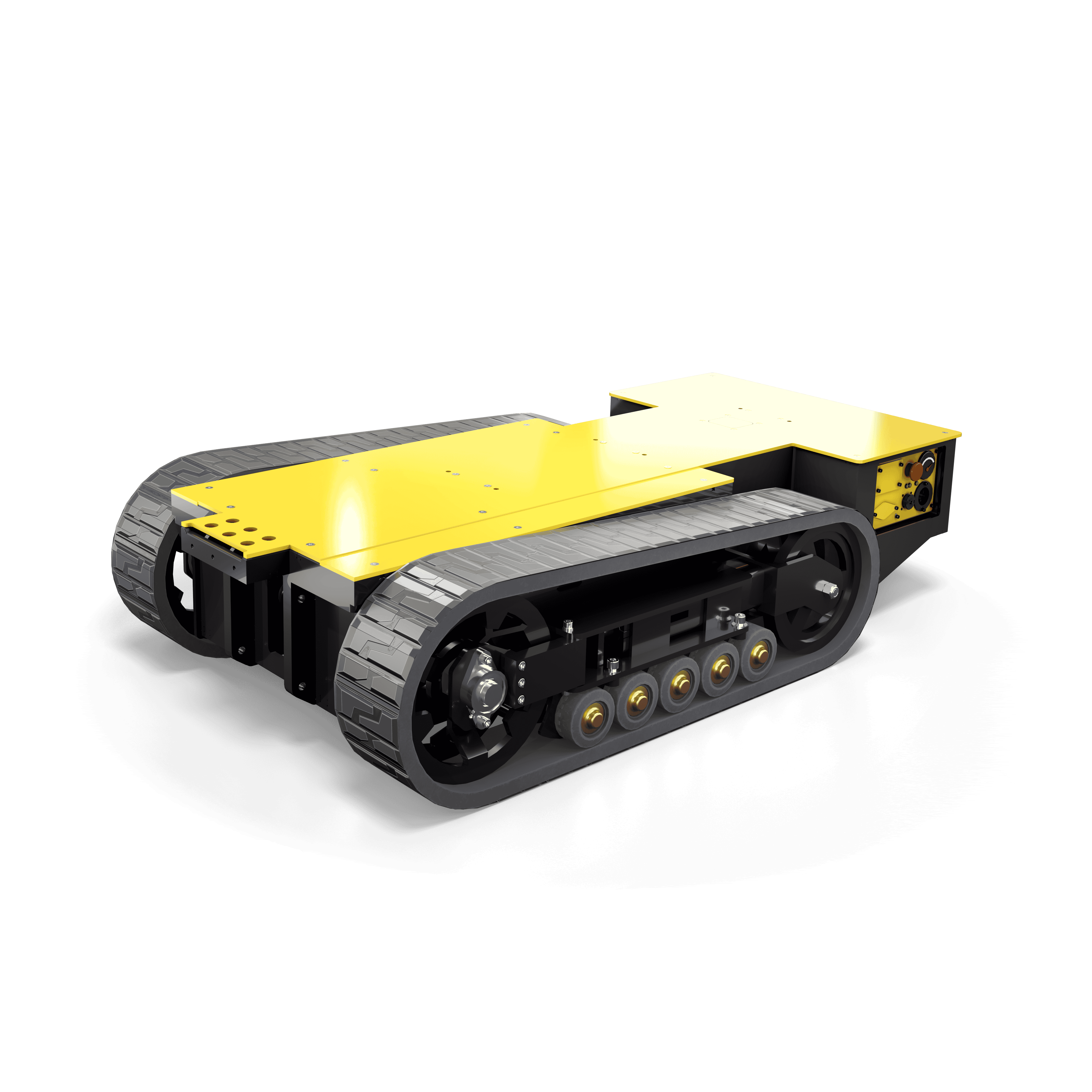

Movex Innovation designs equipment built for the realities of mining: tight spaces, steep inclines, and nonstop schedules. Our heavy duty machines combine compact design with high load capacity, giving teams reliable tools to move material safely and fast where traditional equipment can’t operate.

Here are the most popular heavy mining equipment in Movex Innovation’s material handling line-up:

- Mini dozers and mini loaders (M-27 and M-48) for cleaning up minerals and other bulk material under conveyors without stopping them. There is even a mini loader, the AL-27, for aluminum smelters.

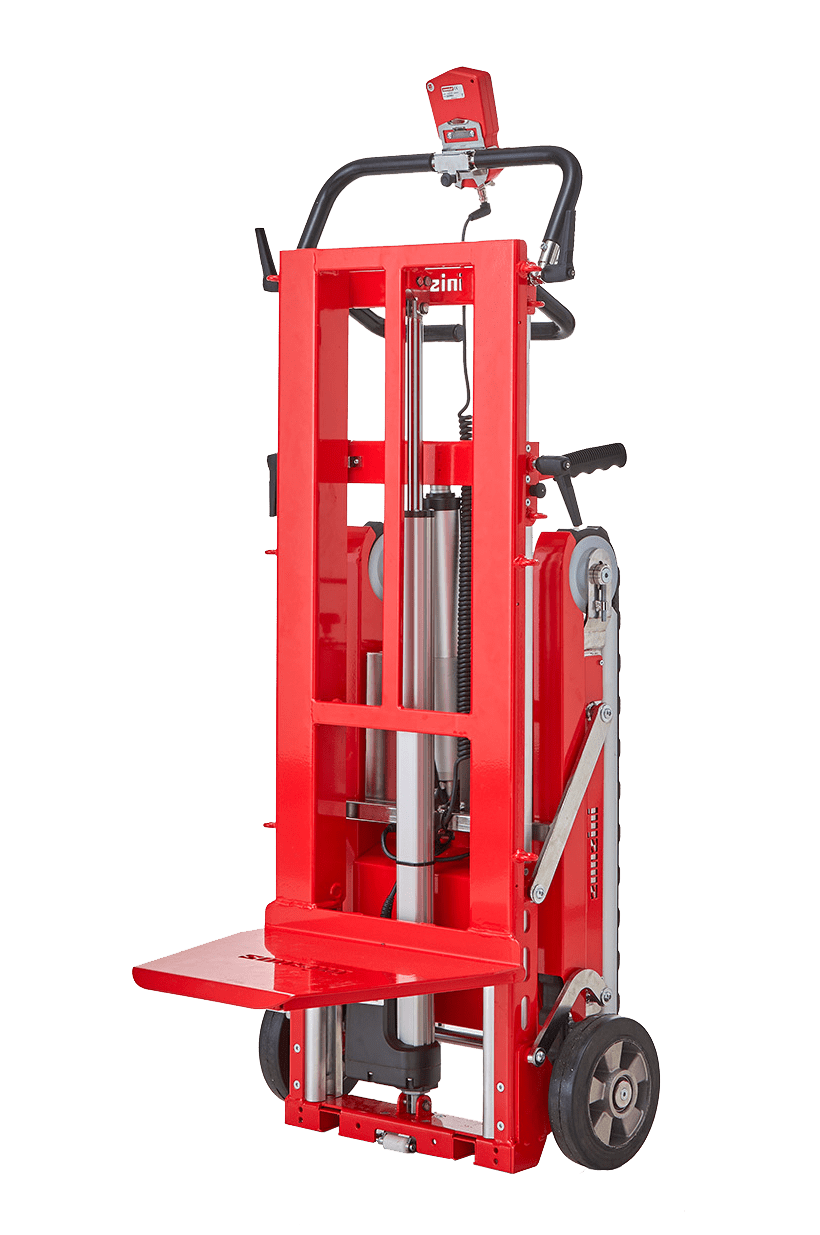

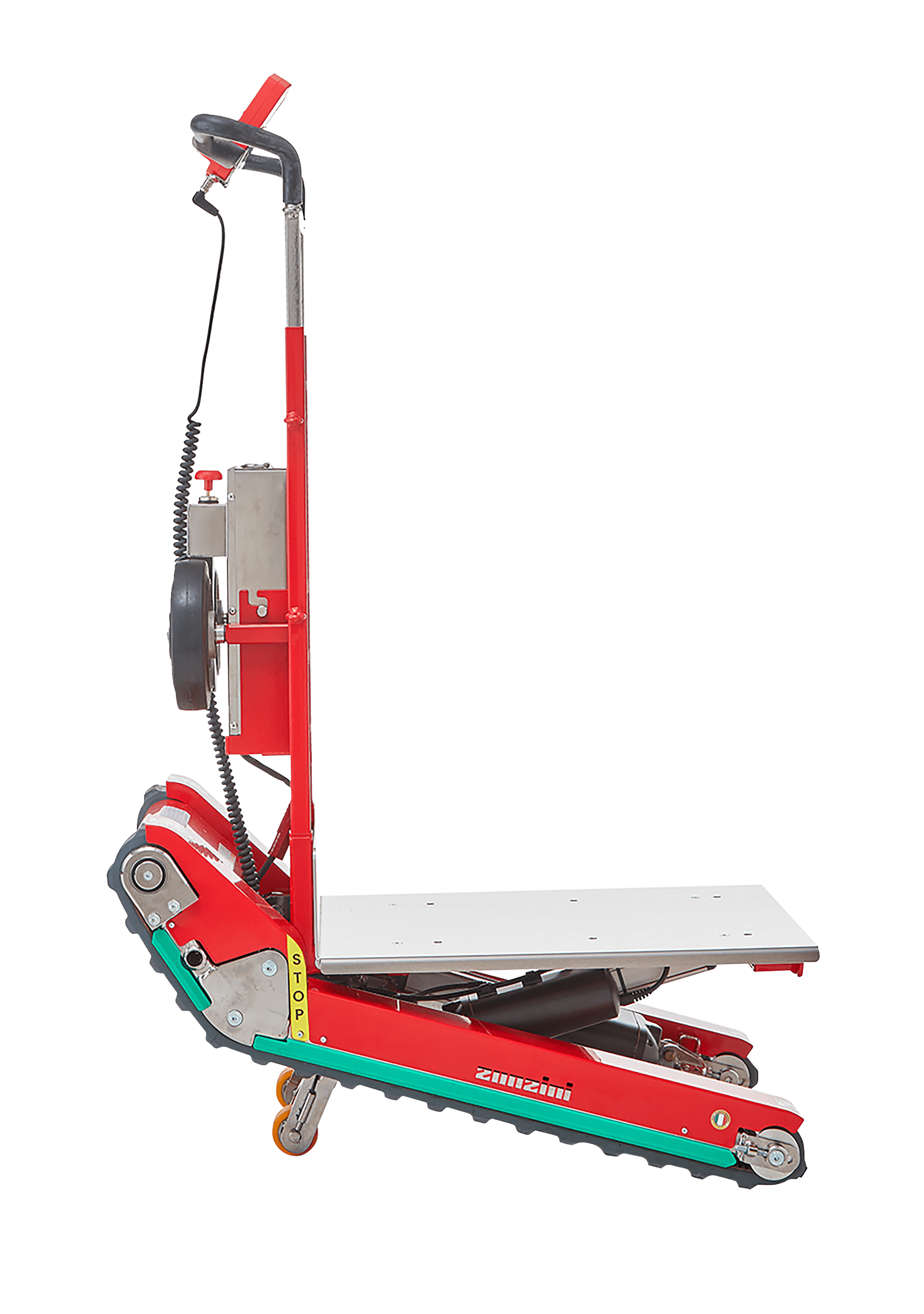

- Stairclimbers (TT-47 and TT-66) For transportation of mechanical parts for maintenance projects, and replacement of conveyor belt rollers, motors and bearings.

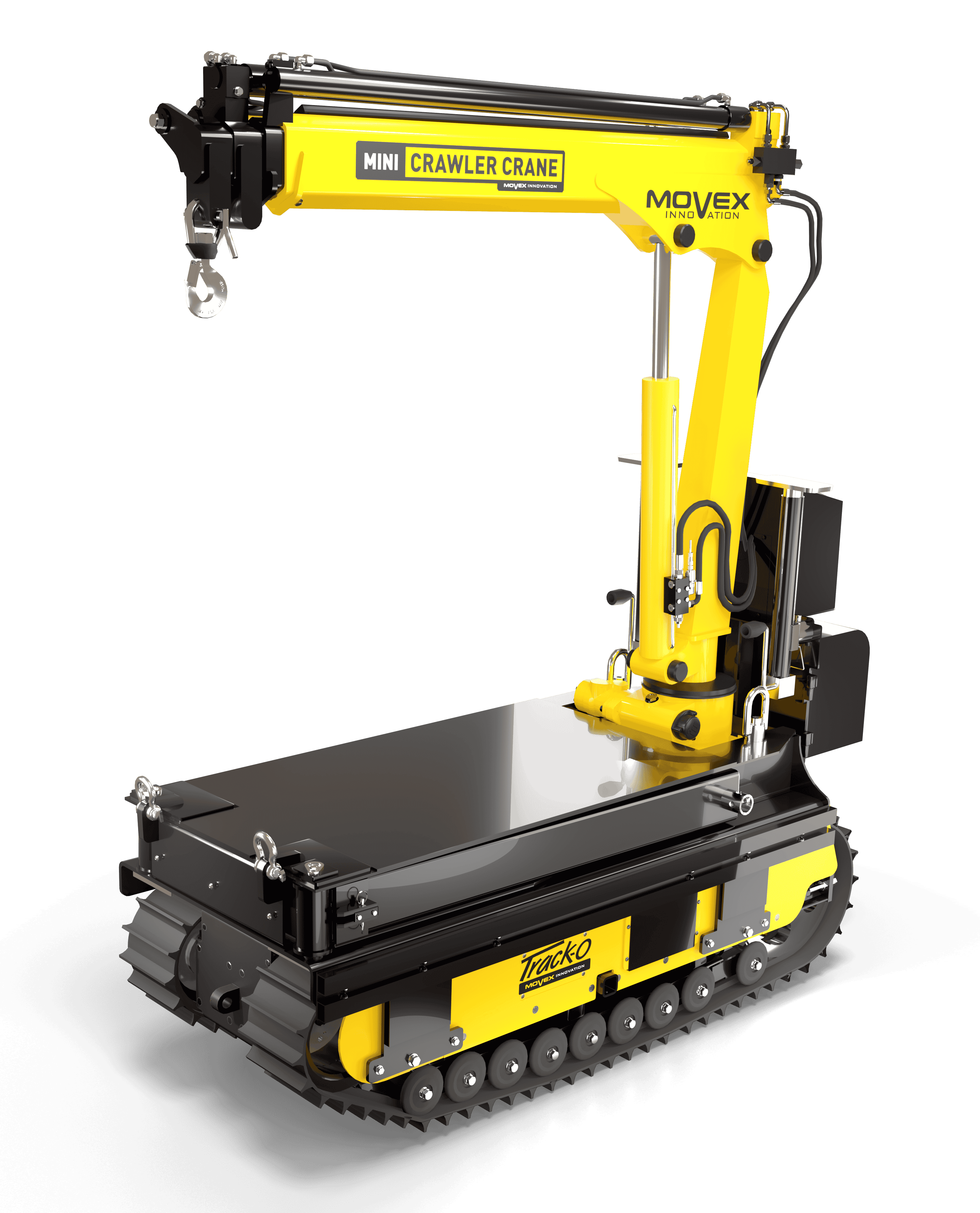

- Mini-Crawler Crane (XC-270) For the heavy handling of pumps, drive assemblies, shaft components and more.

Real-world impact of high-tech material handling solutions

At a mid-sized mine in Newfoundland, unplanned downtimes had become a constant headache. Every time the conveyors jammed with spilled ore, production had to be stopped so crews could clean the area by hand. On average, the mine was losing close to three hours of output per week. This was a period that resulted in hundreds of thousands of dollars in lost revenue each quarter.

When the site introduced compact heavy duty machines designed for cleanup under conveyors, the results were immediate. A mini loader was able to operate directly beneath the belts without shutting them down, keeping material flowing and cutting cleanup time in half. Managers noticed fewer delays, and workers appreciated not having to perform such repetitive, high-risk manual work.

The benefits carried over to maintenance as well. Instead of manually hauling components through narrow access points, operators started using a stairclimber from Movex Innovations’ line of material handling solutions. Jobs that once required six workers and several hours could now be completed in less than half the time with only two operators.

The overall impact was clear: steadier production, safer working conditions, and a measurable reduction in operating costs. For the mine, adopting new heavy handling equipment was not aimed at replacing the workforce; the company wanted to give its employees the right tools to do their jobs faster and safer.

A new era for heavy mining equipment

Mining has always adapted to survive—whether through new methods of extraction, safer work practices, or smarter equipment. What stands out today is the speed of change. Heavy duty machines and advanced material handling solutions are no longer optional; they’re the foundation of a more resilient operation. The sites that invest now in better heavy mining equipment will set the pace for how the sector looks in the decades ahead.

READ OUR LATEST ARTICLES