HVAC Made Easy: Why you should use Zonzini's stair climbing robot

Written by William Nicholls | July 21st 2025

When you’re in the business of building services—HVAC, plumbing, or industrial electrical—you’re not dealing with easy jobs. You’re schlepping heavy equipment into commercial buildings, schools, hospitals, and industrial sites that often lack elevators and easy access.

And when it’s time to replace a rooftop unit or install a furnace in the basement, “good enough” doesn’t cut it. You need a tool that won’t fold under pressure. That’s where the Zonzini and Movex’s stair climbing robots come in.

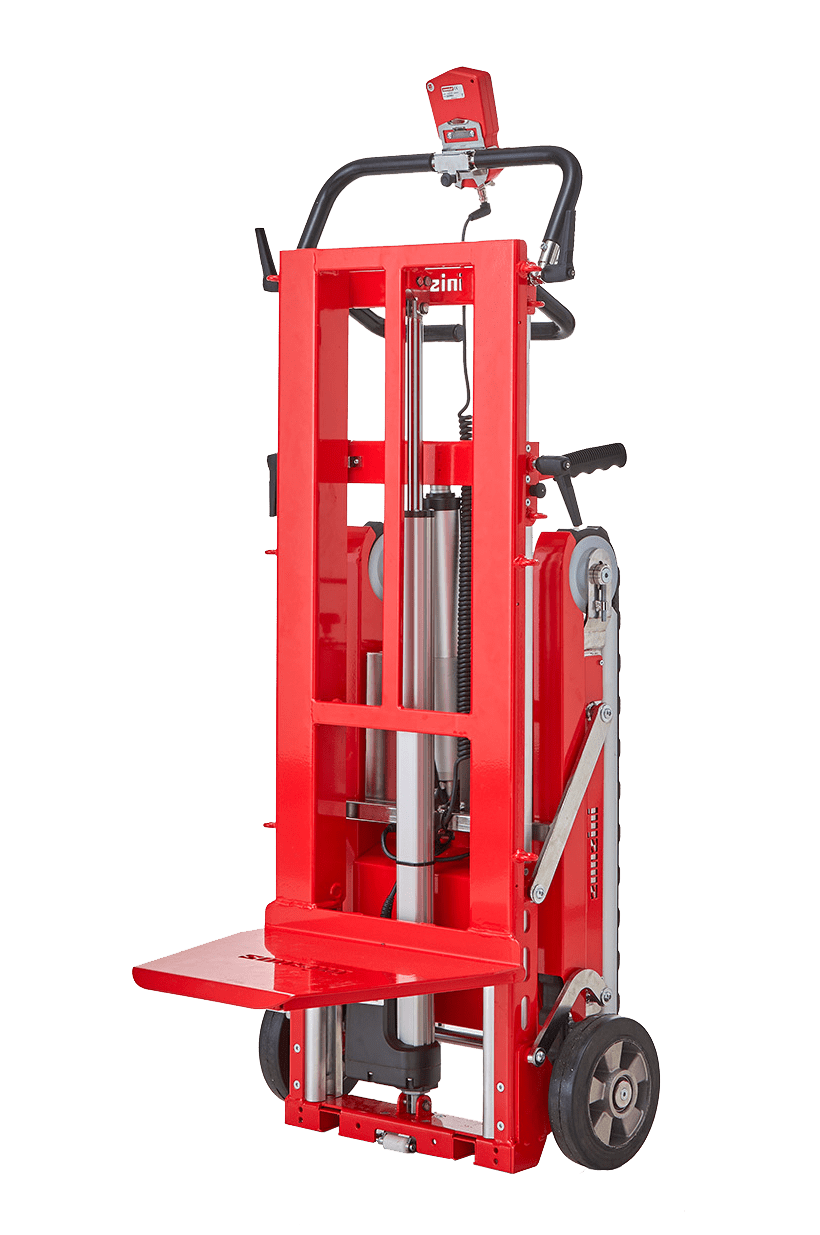

Zonzini’s Domino Plasmoid Stabilized

Built for the hard jobs other material-handling equipment cannot tackle, this machine turns difficult transportation challenges into manageable tasks. No elevators? No problem. Tight stairwells? Handled. Whether you’re installing a new HVAC system in a hospital or replacing an aging furnace in a heritage commercial building, the Domino Plasmoid takes the load…literally.

In this article, we’ll explore how Zonzini’s Domino Plasmoid Stabilized helps mechanical contractors move heavy air conditioning units and heating systems safely, efficiently, and without requiring excessive manpower or risking injuries. It is a go-to stair climbing robot solution you may want to consider for moving HVAC material around.

Safety first: Preventing worker injuries

Let’s be real: lugging HVAC units up stairs is a recipe for injury. Most of these systems weigh anywhere from 100 to over 500 pounds. Some industrial models exceed the thousand-pound mark. That’s not “grab a buddy and muscle it up” territory. That’s back strain, knee damage, and shoulder blowouts waiting to happen.

One wrong move on the stairs can take a technician out for weeks or worse. And with growing labor shortages, no contractor can afford injured workers or rising compensation claims.

The Zonzini stair climbing robot removes the physical burden from your crew. No manual lifting. No dangerous pivoting on narrow landings. Just controlled, motorized stair climbing that makes brutal jobs safer to execute. Fewer injuries mean less downtime, lower insurance costs, and a team that’s still carrying out jobs by the end of the week.

Protect customers’ properties

It’s not just your team that’s at risk. Manually dragging massive HVAC or water systems up a staircase can wreck a client’s property in no time. Scratched floors, gouged drywall, cracked stair treads: those “oops” moments cost more than just a repair invoice. They cost customer trust.

Whether it’s a newly finished commercial space or a 40-year-old institutional building, your team is expected to leave it the way they found it. That’s tough to guarantee when you’re balancing 500 pounds of steel and wiring on a tight landing.

Zonzini’s Domino Plasmoid Stabilized provided controlled and smooth powered movement, securing its grip on each step. It drastically reduces the risk of bumps, slips, or sudden drops. That means fewer property damage claims and more repeat business.

Speed and efficiency

Manually hauling an HVAC unit up a flight of stairs can kill your schedule. Two or more workers can take up to 30 minutes or more wrestling with a single piece of equipment. That’s half an hour of grunt work that could’ve been spent doing actual installs.

With the Zonzini stair climbing robot, one technician can move the same unit solo, safely, and in a fraction of the time. No need to wait for extra hands or block off additional staff members for a single lift. Imagine the time and labour costs saved with, for example, air conditioner transportation in a huge, multi-unit dwelling construction project!

The immediate impact? Faster jobs, tighter turnarounds, and more installations on the books each and every day. When time is money (and in this industry, it always is), every saved minute counts.

Tackling challenging sites

Not every jobsite plays nice. HVAC units don’t always go into wide-open mechanical rooms with freight elevators. Sometimes they’re headed for a basement with a steep concrete stairwell, a third-floor attic with a narrow turn, or a retrofit in a century-old building that was never meant for modern infrastructure.

This is where traditional dollies and brute force hit their limits—and where the Domino Plasmoid stair climbing robot proves its worth.

Engineered for tight spots, steep angles, and awkward layouts, the robot handles what your manpower can’t muscle through. It maneuvers precisely, even on winding or uneven stairs, keeping the load stable and the job moving forward.

Improved professionalism

How you show up matters. When a customer sees your workers struggling with a thousand-pound HVAC unit up the stairs with a couple of straps and a prayer, it doesn’t exactly scream “professional.”

But when you roll in with purpose-built equipment like the Zonzini stair climbing robot, it sends a clear message: you take the job and their property’s condition seriously. It tells clients you’re modern, prepared, and committed to doing things the right way.

In a competitive industry where word of mouth is everything between winning or losing contracts, that kind of credibility gives you an edge.

Reduced labour costs

You really don’t want to hire skilled tradespeople just to move gear up a staircase. But when you don’t have the right equipment, that’s exactly where your payroll goes—into grunt work.

The Domino Plasmoid stair climbing robot cuts those wasted hours. Instead of tying up two or three techs for a single delivery or removal, one trained operator gets it done safely and efficiently. That frees up the rest of your team to do what they’re actually paid to do: install, wire, plumb, and troubleshoot.

Fewer labour hours per project. Less burnout. More value from every worker on site.

Adapting to a tight labour market

Good labour is hard to find and even harder to keep. When you’re running short-staffed, the last thing you need is a job that requires three people just to get a unit up a flight of stairs.

If you’re facing labor shortages, stair climbing robots help one person do the work of two or three, allowing your team to stay productive without increasing headcount.

Stair climbing robots: Tailored for different trades

The Domino Plasmoid stair climbing robots have been designed with building services in mind. Whether your crew handles HVAC, electrical, or plumbing work, this machine is built to meet the demands of your trade.

HVAC contractors

From furnaces and condensers to bulky air handlers, HVAC equipment is heavy, awkward, and often packed with sensitive components. The Domino Plasmoid keeps loads upright and stable, which is critical for systems containing refrigerants or compressors. And when access points are in basements or rooftops, their precise stair-climbing capabilities are a game-changer.

Electrical contractors

Transformers, switchgear, UPS systems, and battery banks are heavy and fragile. One bad bump on a stairwell and you’re looking at serious equipment damage. The stair climbing robot moves these units smoothly and securely, reducing shock and vibration. It’s a must-have for jobs in data centers, office towers, and other locations where elevators aren’t an option.

Plumbing contractors

Transporting a water heater down a tight stairwell is risky, leading to dented tanks and flooded floors. With the Domino Plasmoid Stabilized, you can move boilers, pressure tanks, and pumps cleanly and confidently, even in multi-story buildings. It protects both the equipment and the property, which means fewer callbacks and headaches.

Interested in learning more about the Domino Plasmoid?

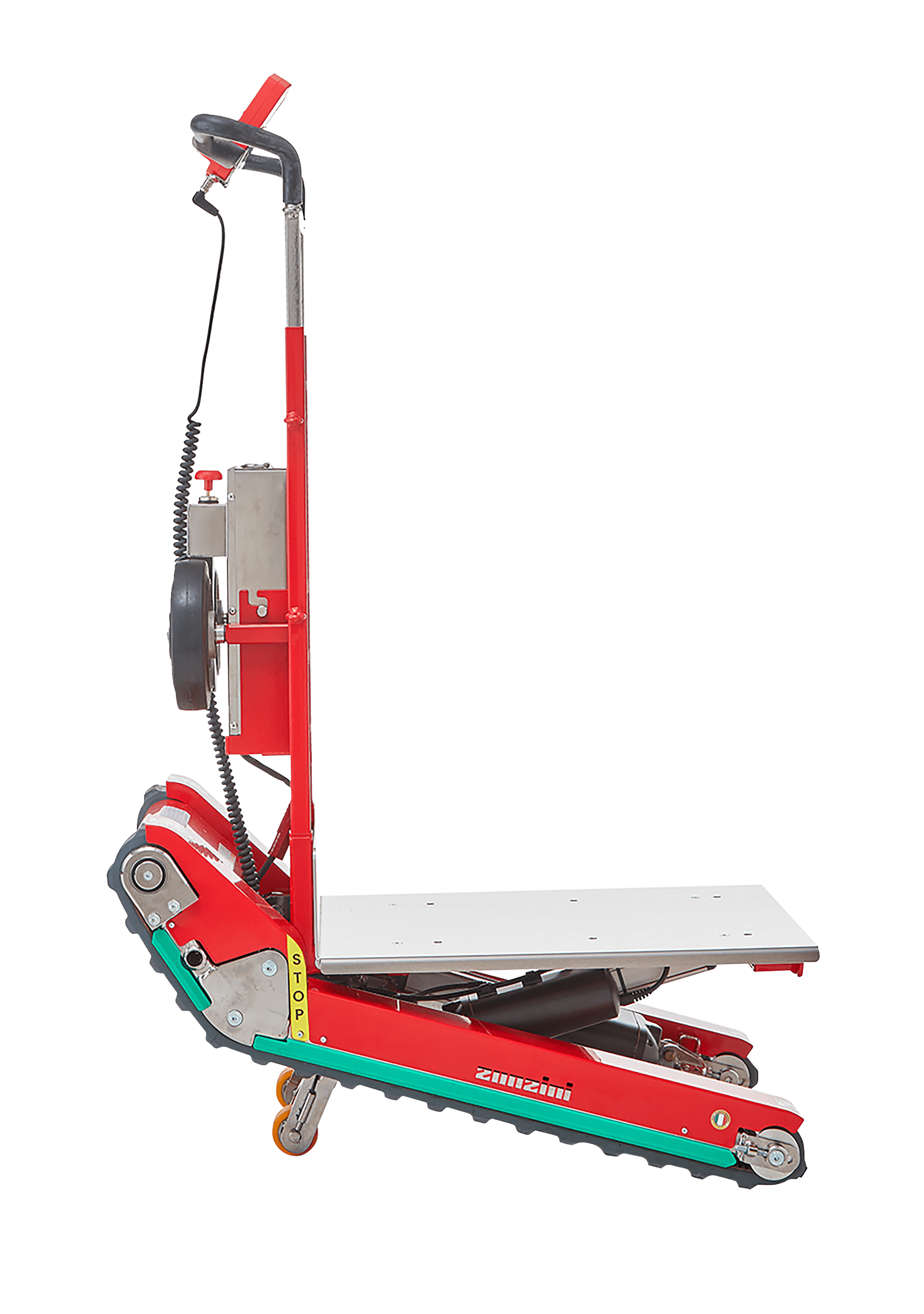

Choosing the right tool for the job: Domino Plasmoid or TT-66?

While many building service contractors can rely on the Zonzini Domino Plasmoid for the majority of their work, there are times when you may need material handling equipment that can handle heavier loads.

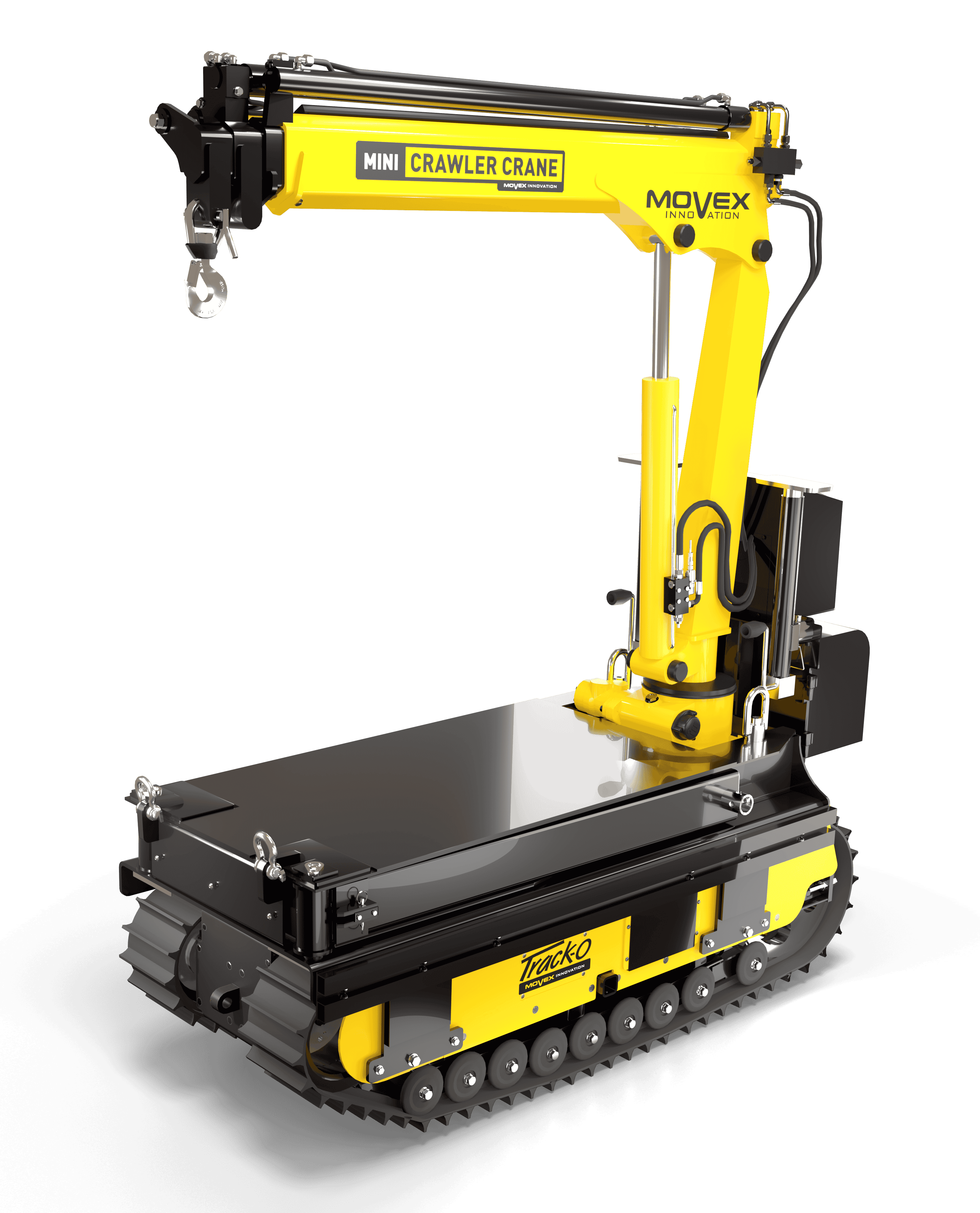

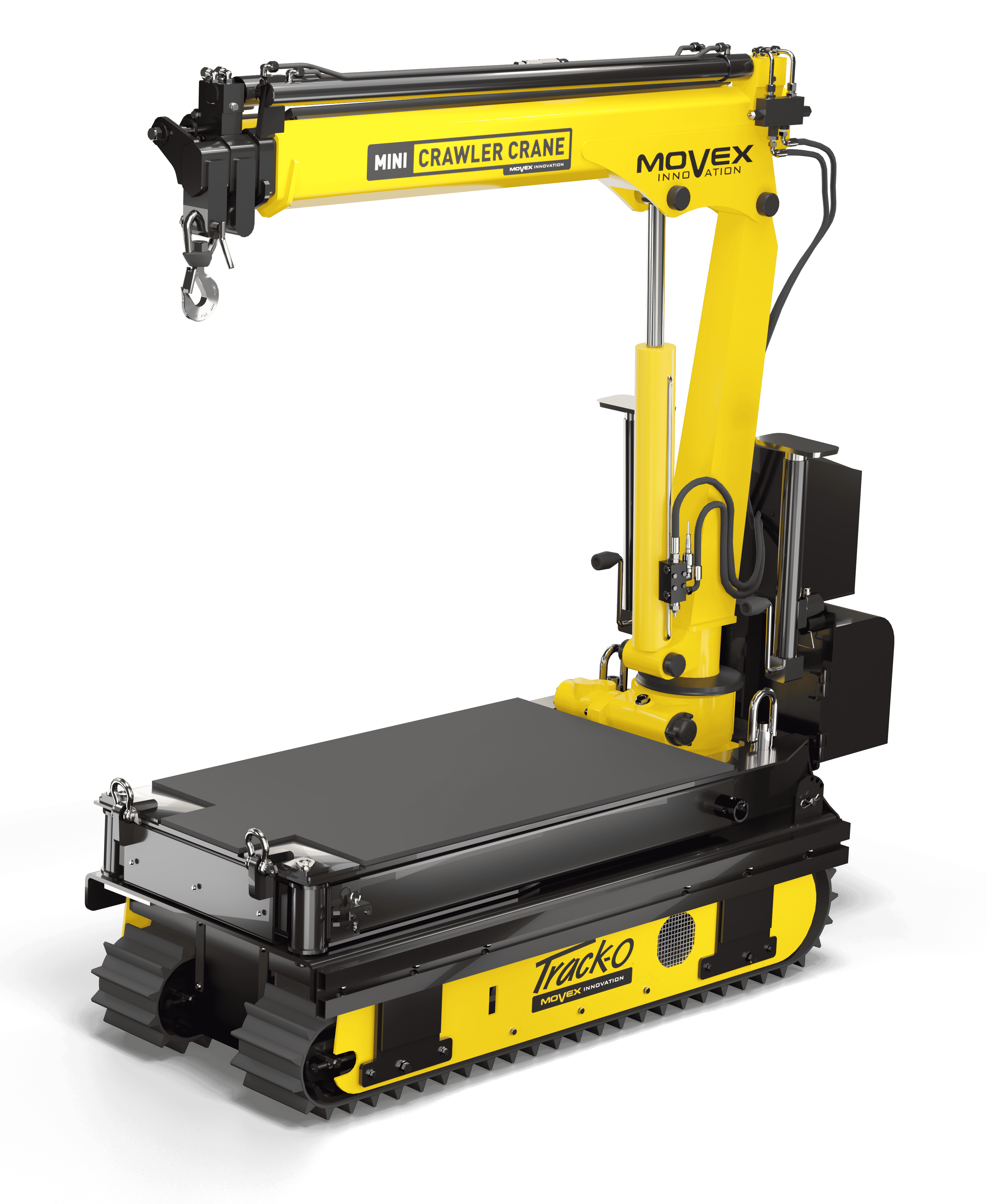

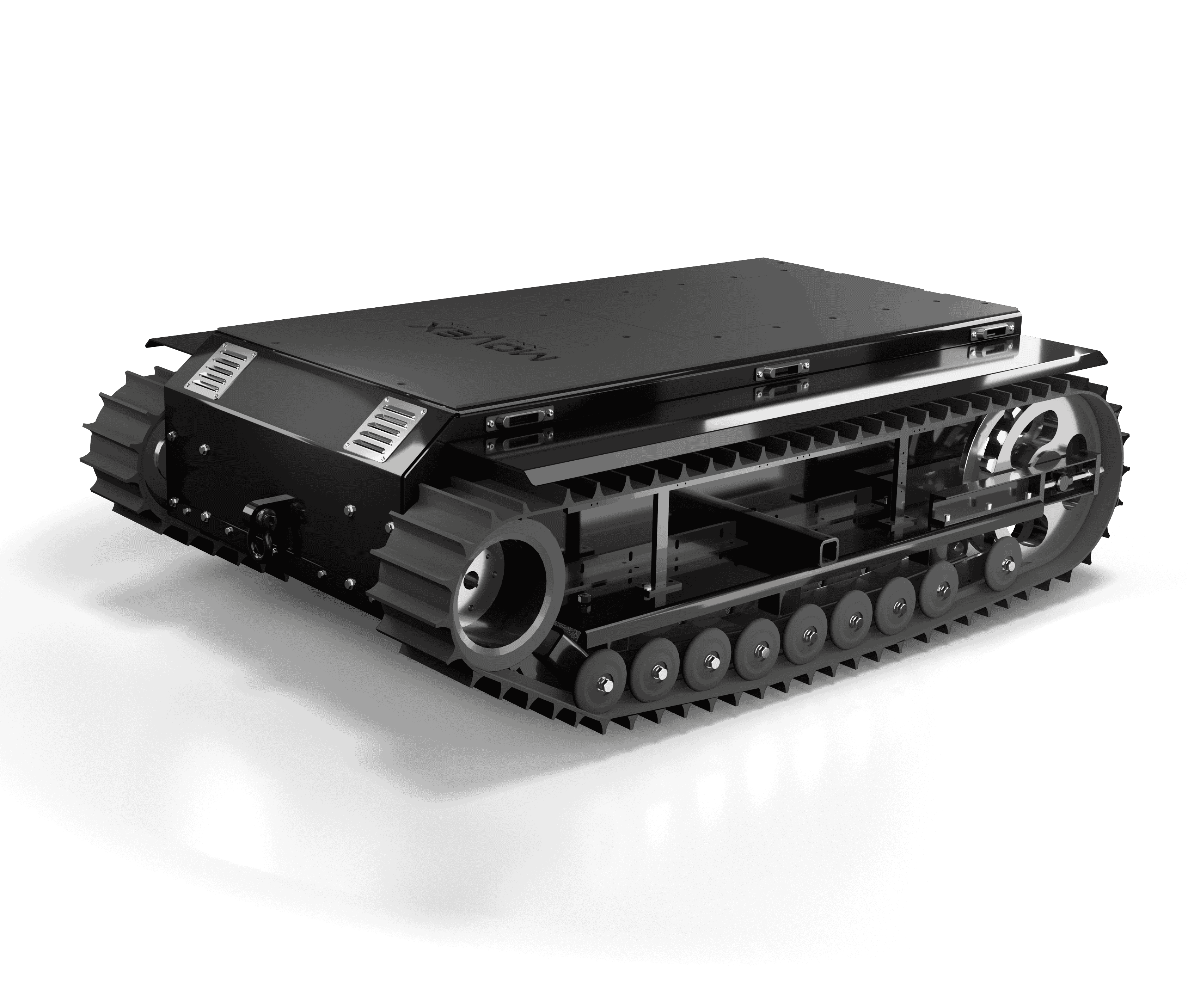

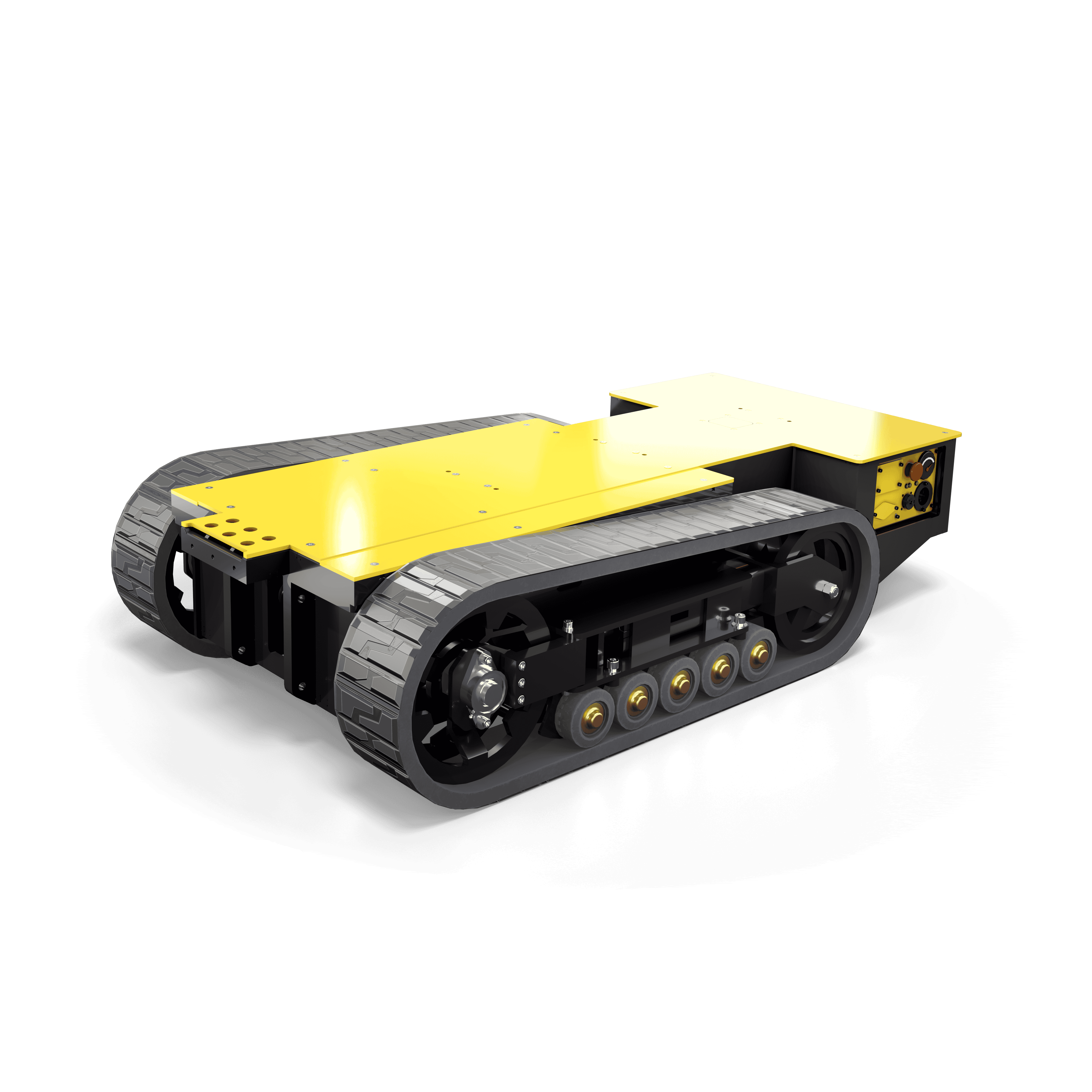

For loads under 880 lbs, the Domino Plasmoid gets the job done. But once you’re pushing 900 lbs or more, it’s time to bring in the heavy hitter: Movex Innovation’s TT-66 tracked carrier.

For oversized equipment and extreme-duty jobs, the TT-66 handles up to 1800 lbs with ease. This beast of a machine is built for steep, narrow staircases and brutal commercial environments where equipment weight, dimensions, and access are all working against you.

Here’s what sets the TT-66 apart:

- The stair climbing robot with the highest staircase load capacity on the market

- The sturdiest stair climber on the market, capable of transporting heavy staircase loads in harsh environments, such as mines and construction sites

- The best and safest stair climber for industrial applications

- The most customizable stairlift on the market, with over a hundred options and accessories

- High load capacity on flat surfaces

- Remote controlled

- Ultra-compact

- Electric / Zero emissions

Which stair climbing robot is right for you?

READ OUR LATEST ARTICLES